Pepper drying equipment

A technology of drying equipment and chili peppers, which is applied in the direction of sounding equipment, food preservation, instruments, etc., can solve the problems of weather influence, increased production costs, troubles, etc., and achieve the effect of reducing noise and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

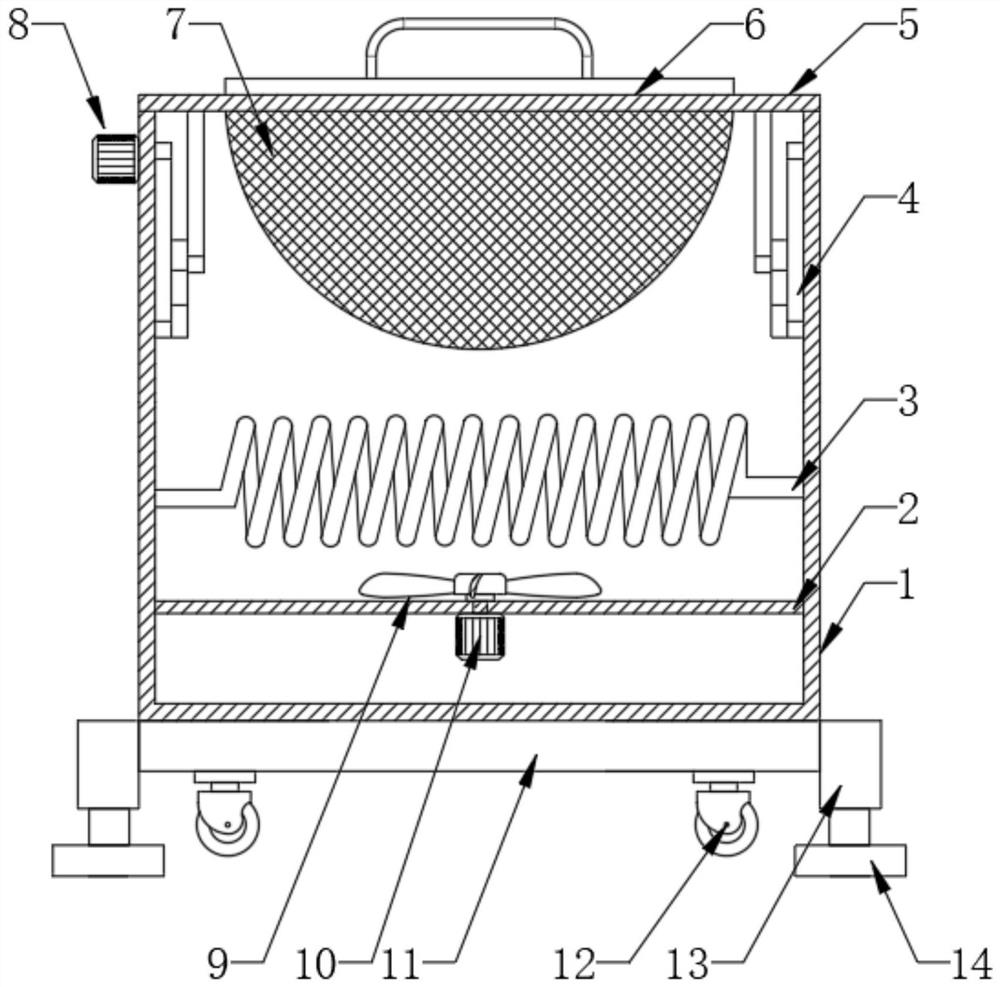

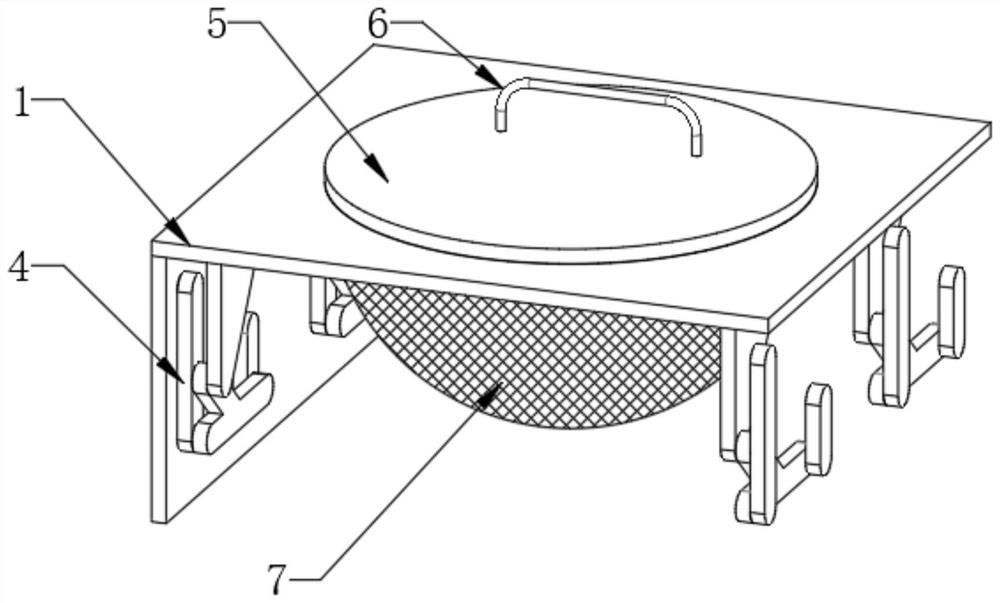

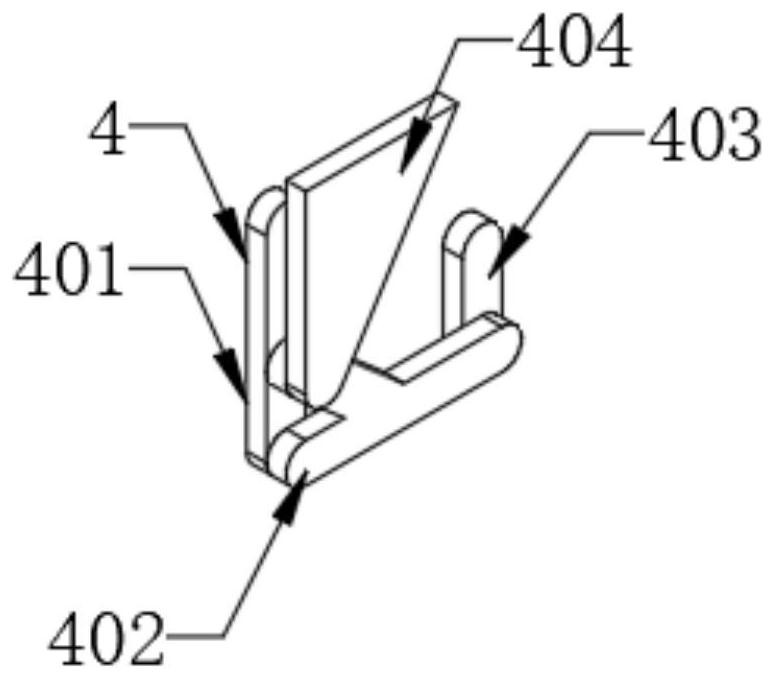

[0026] refer to Figure 1-3 , a pepper drying equipment proposed by the present invention includes a box body 1, a motor 8 is fixed on one side of the box body 1 by screws, and the motor 8 is connected to a shaking mechanism 4 through a coupling, and the shaking mechanism 4 includes a second Three connecting rods 403, the bottom end of the outer wall on one side of the third connecting rod 403 is rotatably connected to the second connecting rod 402, and the outer wall on one side of the second connecting rod 402 is rotatably connected to a support block 404, and one side of the second connecting rod 402 The outer wall is rotatably connected with a first connecting rod 401, and the top end of the outer wall on one side of the first connecting rod 401 forms a rotational fit with the box body 1, and the end of the third connecting rod 403 away from the second connecting rod is connected with the motor 8 through a coupling .

[0027] In the present invention, the support block 40...

Embodiment 2

[0030] refer to Figure 4 , a pepper drying equipment, compared with Embodiment 1, this embodiment also includes four to six equidistantly distributed springs 15 fixed on both sides of the top outer wall of the box body 1 by screws.

[0031] Working principle: When the equipment is working, the top plate 5 will hit the box body 1 and generate noise. The spring 15 exists, which can convert the dynamic potential energy generated by the top plate 5 into elastic potential energy and release it at the same time, which can reduce the generation of noise and reduce the noise. The damage of the small top plate 5 to the casing 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com