A hollow split conductive plastic potentiometer

A conductive plastic, split-type technology, applied in the direction of sliding contact resistors, etc., can solve the problems of shaft deviation, accuracy and service life not as expected, high shaft accuracy requirements, etc., to achieve the effect of large tolerance and reduced installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

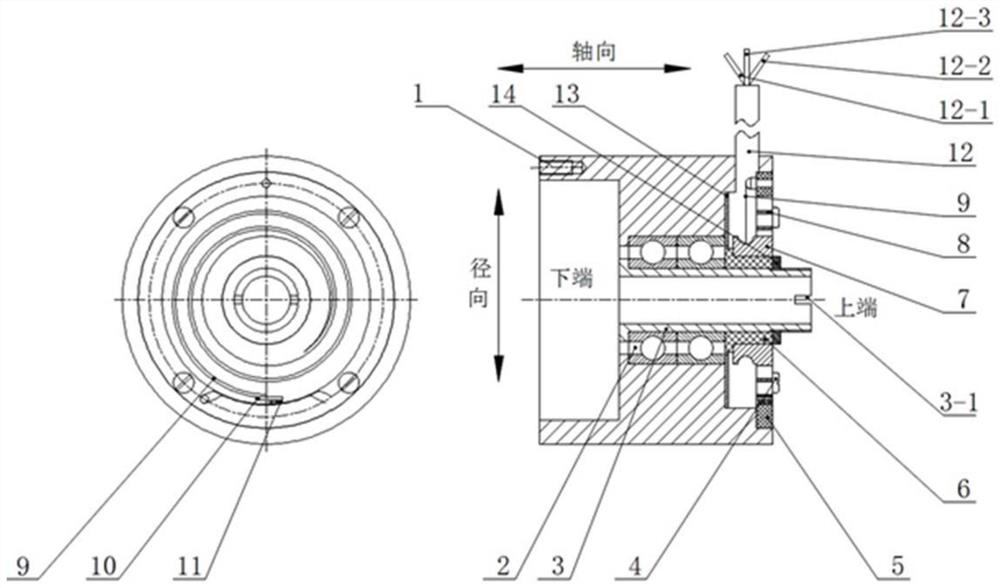

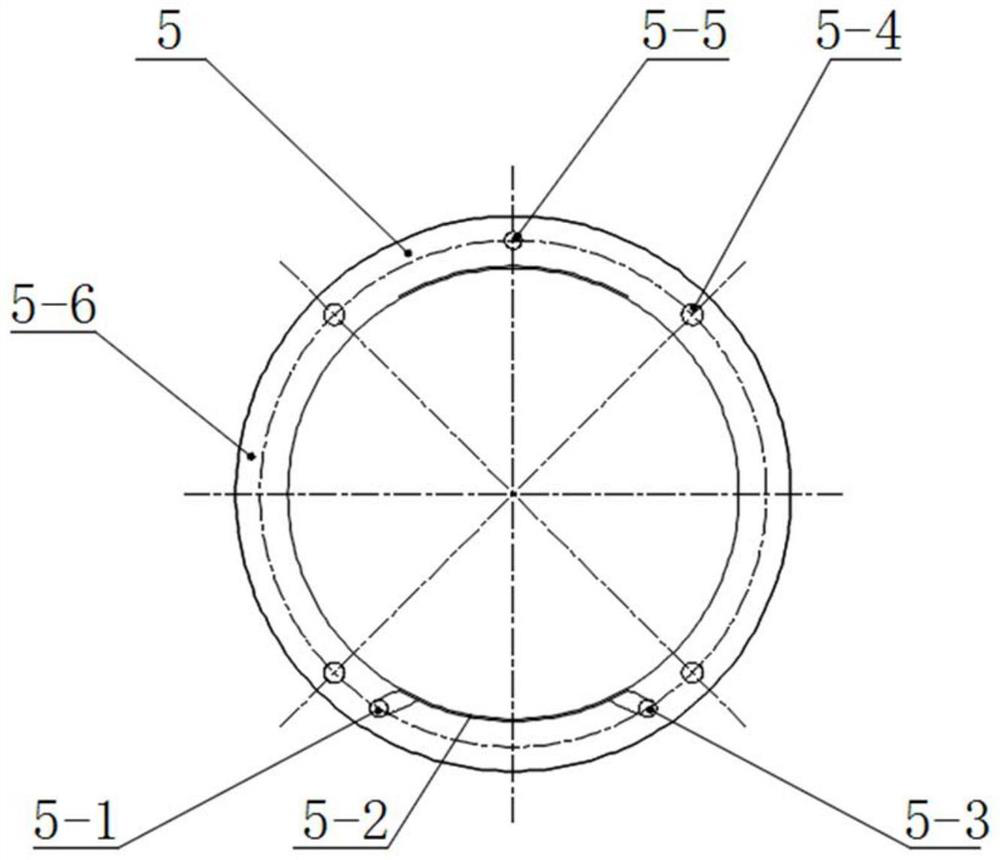

[0021] A hollow split-type conductive plastic potentiometer, which is installed separately and uses a hollow hollow shaft to design cables, air passages, and transfer shaft channels. The number of spring coils, pitch, radial elastic deformation, and radial elastic pressure The torque design enables the planar spring to meet the working requirements of the potentiometer. At the same time, an arc-shaped resistor body made of conductive plastic is arranged in the conductive matrix, which reduces the required installation accuracy and ensures large radial and axial clearance tolerances. Split installation can be realized, such as figure 1 As shown, including base-1, bearing-2, hollow shaft-3, screw-4, conductive base-5, insulating bushing-6, conductive ring-7, plane spring-8, current collector-9, contact spring Sheet-10, brush-11, lead-out cable-12, block-13, pressing block-14, of which:

[0022] The base is fixed on the external mechanism through the threaded hole set at the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com