Semi-closed double-jet-airflow arc extinguishing lightning protection device without air gap and application thereof

A jet airflow, semi-closed technology, applied in the direction of spark gaps, electrical components, spark gap components, etc., can solve the problems of multi-chamber arc extinguishing sensitivity, low durability, and arc extinguishing dead zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

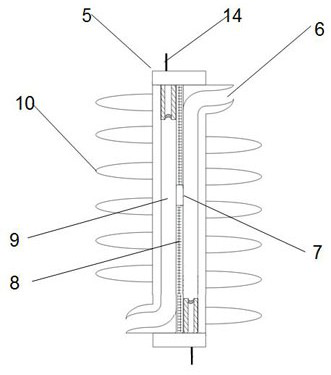

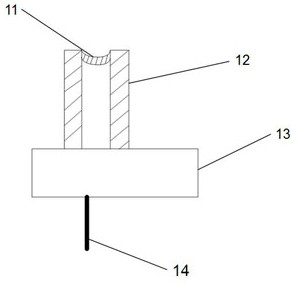

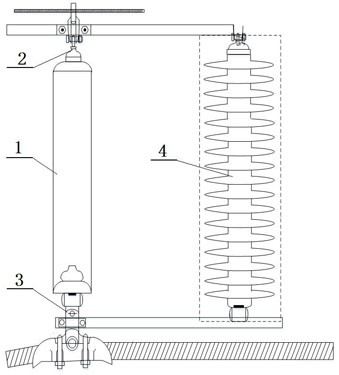

[0032] Such as figure 1 As shown, a semi-closed double-jet airflow arc extinguishing and lightning protection device without air gaps includes an arc extinguishing body 4 and a jet air flow assembly 5; the interior of the arc extinguishing body 4 is a hollow structure, and in the middle The position is also provided with a partition 8 longitudinally, and the partition 8 divides the inner space of the arc extinguishing body 4 into two groups of jet air passages 9, and the partition 8 is provided with a wall electrode 7; the jet air passage on the left side An air jet assembly is fixedly installed at the upper end of the upper end of the arc extinguishing body, and an air jet nozzle extending to the side of the arc extinguishing body is installed at the lower end; an air jet nozzle extending toward the side of the arc extinguishing body is installed at the upper end of the jet air flow channel on the right side, and a jet air flow assembly is fixedly installed at the lower end ;...

Embodiment 2

[0037] Such as Figure 4 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the wall electrode 7 uses a compressed arc extinguishing tube. The compression arc extinguishing tube adopts a ceramic tube, and an arc-guiding metal ball is placed in the middle of the tube.

Embodiment 3

[0039] Such as Figure 5 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the wall electrode 7 uses a recoil tube. The recoil pipe is a semi-closed pipe with one end open and the other end connected to the lightning pole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com