Ball valve for sampling, natural gas hydrate fidelity sampler and sampling method

A sampler and ball valve technology, applied in the sampling field of energy development, can solve the problems of limited pressure holding effect, complex sealing process and sealing structure of natural gas hydrate sampler, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

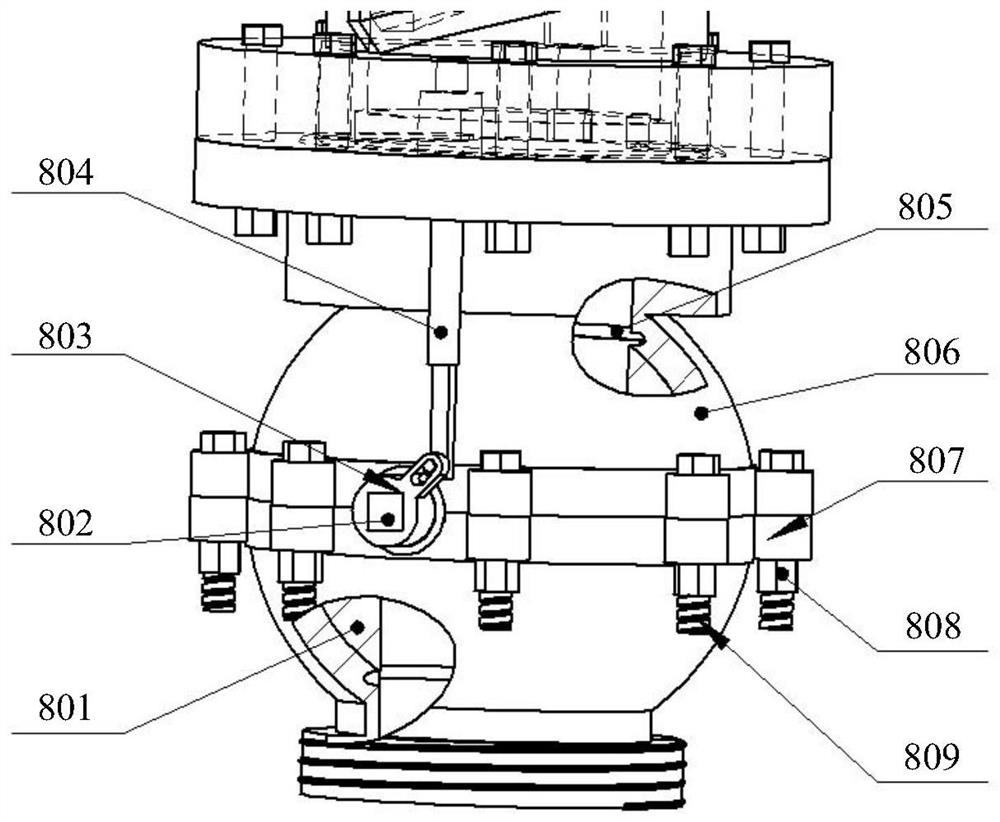

[0048] Such as figure 1 and figure 2 A ball valve for sampling is shown, which includes a matching shell and a valve core 801, the valve core 801 is fixedly connected with a pin 802 that is partially located outside the shell, and the part of the pin 802 that is located outside the shell cooperates with the steering head 803; The first piston 804 that drives the steering head 803 to rotate. One end of the bolt 802 is fixedly connected with the valve core 801, and the other end protrudes out of the casing; and the end of the bolt 802 outside the casing is polygonal, and the steering head 803 includes a square hole matching the polygon; the steering head 803 is sleeved on the bolt 802 outside. Sealing rubber rings 805 matching with the valve core 801 are provided on both ends of the housing.

[0049] In this embodiment, the pressure accumulator in the fidelity sampler is used as the power source of the first piston 804. The pressure accumulator releases pressure to push the ...

Embodiment 2

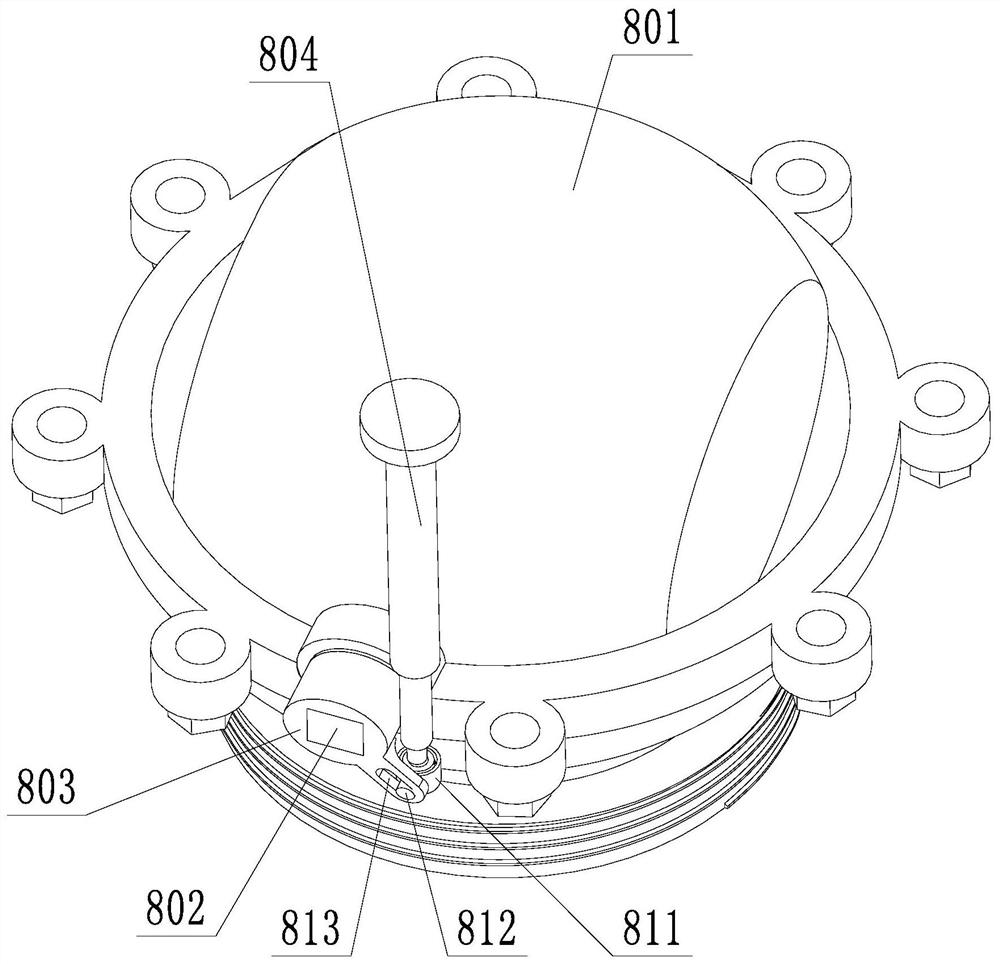

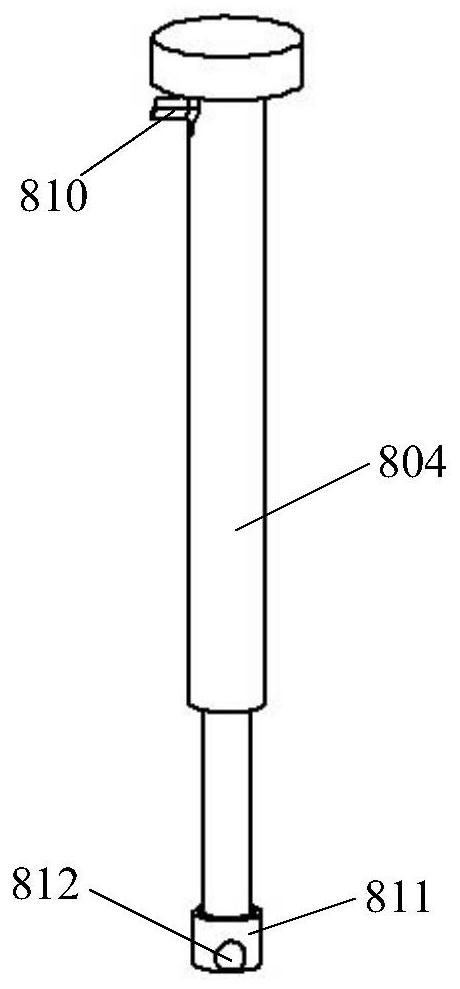

[0052] Such as Figure 1 to Figure 3 In the shown ball valve for sampling, on the basis of Embodiment 1, a boss 810 is set on the first piston 804, and a spiral track matching the boss 810 is set on the housing, and the boss 810 slides and fits in the spiral track The output end of the first piston 804 is connected to the bearing 811, the bearing 811 is fixed with the guide post 812, the steering head 803 is provided with a waist-shaped hole 813 matching the guide post 812, and the guide post 812 is slidably fitted in the waist-shaped hole 813.

[0053] When the present embodiment works, the first piston 804 moves downward as a whole. Due to the limitation of the boss 810, it can only rotate downward along the spiral track on the housing, and the output end of the first piston 804 is fitted with a bearing, so the upper end of the first piston 804 The guide post can not be rotated, but still keeps going straight down. The guide post moves in the waist-shaped hole and at the sam...

Embodiment 3

[0055] Natural gas hydrate fidelity sampler, such as Figure 4 As shown, it includes a sleeve 9, a pilot drill 7 located at the lower end of the sleeve 9, and an inner cylinder 4 located inside the sleeve 9. The lower end of the inner cylinder 4 is connected to the claw 5 and the valve 6 in turn, and a pressure accumulator is arranged inside the sleeve 9. 3. The valve 6 is a ball valve for sampling, and the first piston 804 is powered by the pressure accumulator 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com