Inspection robot rail for coal mine fully mechanized face and rail traveling method

A technology for inspection robots and fully mechanized mining faces, which is applied to supporting machines, mechanical equipment, railway inspection vehicles, etc. It can solve the problems of difficult disassembly and assembly of rails and poor walking of inspection robots, and achieves convenient installation and disassembly, which is beneficial to mines. Equipment management, making simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention will be described completely and clearly below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, not all of them.

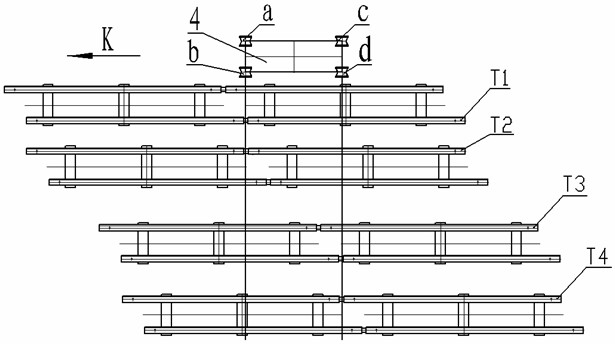

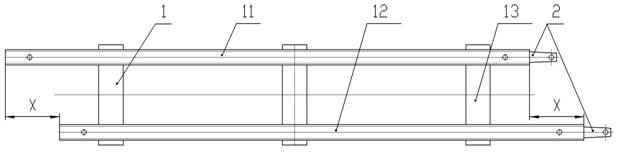

[0023] The invention provides an inspection robot track for fully mechanized coal mining face, such as figure 1 As shown, it includes a track body 1, a taper pin 2, and a bolt 3; the track body 1 is welded by a round tube a, a round tube b, and a connecting plate 13, and the round tube a and the round tube b are staggered by a certain distance X.

[0024] figure 2 As shown, the distance L of the overlapping section of the two rail bodies 1 is 1.5 times the diameter D of the rubber wheel of the inspection robot.

[0025] image 3 As shown, the tapered pin 2 is inserted into the round pipe a and the round pipe b, and the tapered pin 2 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com