Inner wall pre-repairing pipeline for petroleum transportation

A pre-repair, pipeline technology, applied in the direction of pipe components, pipes/pipe joints/fittings, machinery and equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

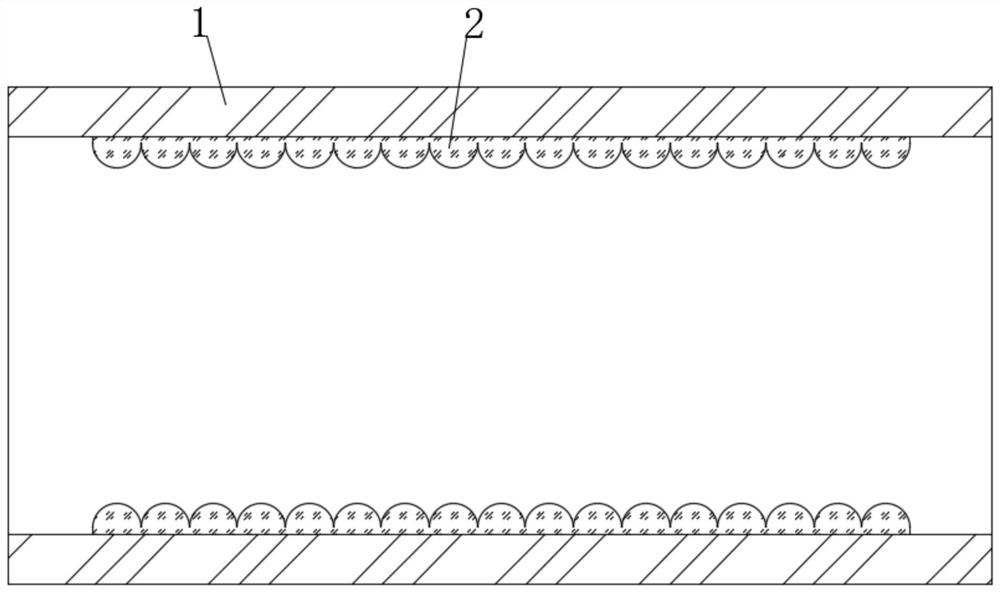

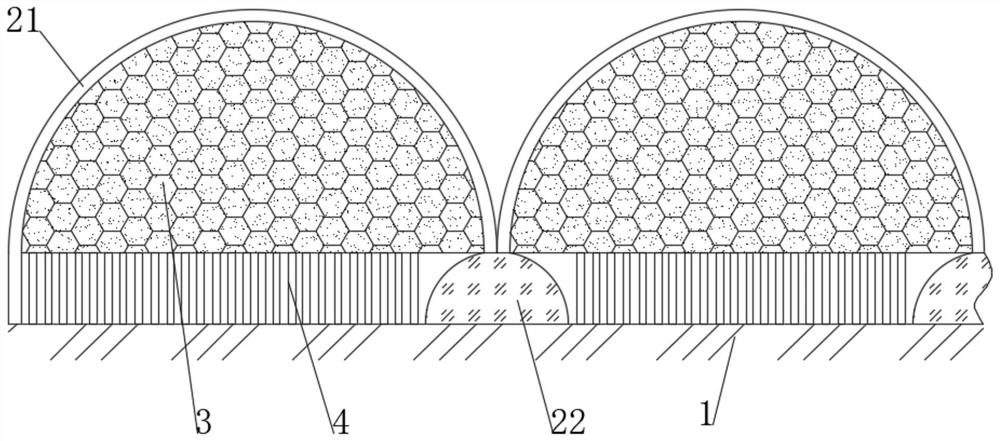

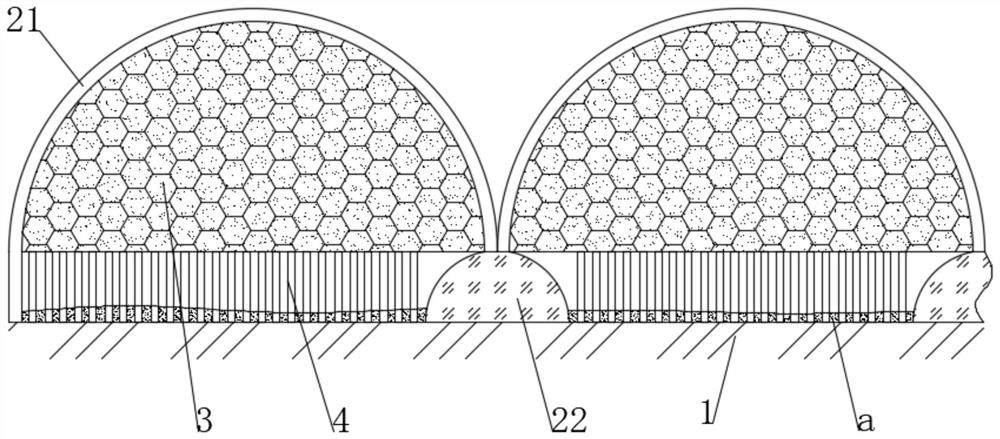

[0041] see figure 1 , a pre-repaired inner wall pipeline for oil transportation, comprising a pipeline body 1, the inner wall of the pipeline body 1 is fixedly connected with a pre-repaired undulating ring layer 2, please refer to figure 2 The pre-repair undulating ring layer 2 includes a plurality of evenly distributed inner convex layers 21, two adjacent inner convex layers 21 are in contact with each other, and the ends of the outermost two inner convex layers 21 that are far away from each other are fixedly connected to the inner wall of the pipeline body 1 An outer concave ball 22 is fixedly connected between one end of two adjacent inner convex layers 21 in contact with the inner wall of the pipeline body 1, and the inside of the inner convex layers 21 close to each other is fixedly filled with a powder overflow layer 3, and the powder overflow layer 3 is connected to the pipeline. A plurality of evenly distributed spill rods 4 are fixedly connected between the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com