Engine driving device

An engine-driven and passive technology, applied in the field of mechanical transmission, can solve the problems of inability to realize fast power engagement and disengagement switching, complicated mechanism, and increased overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

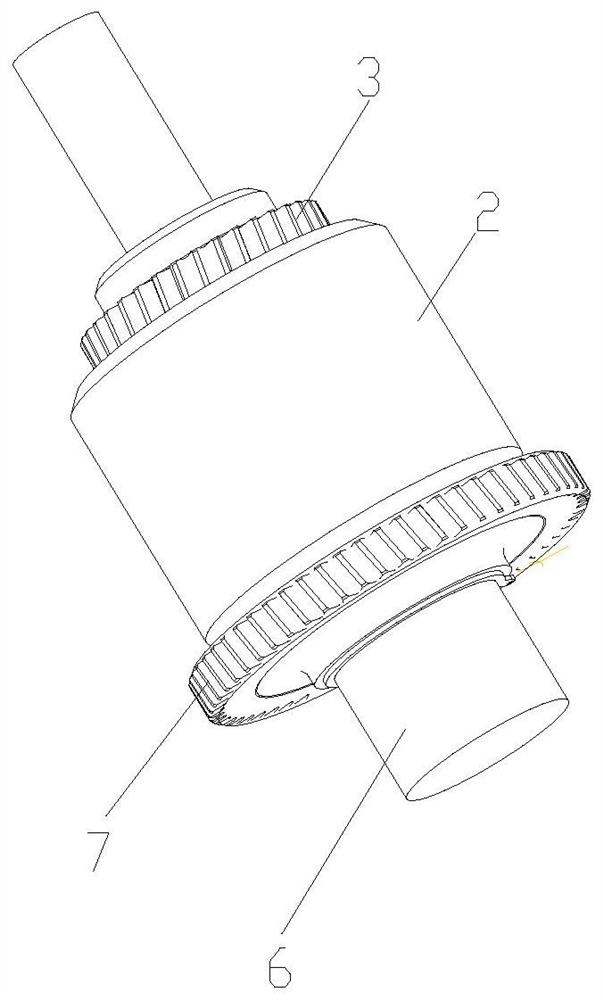

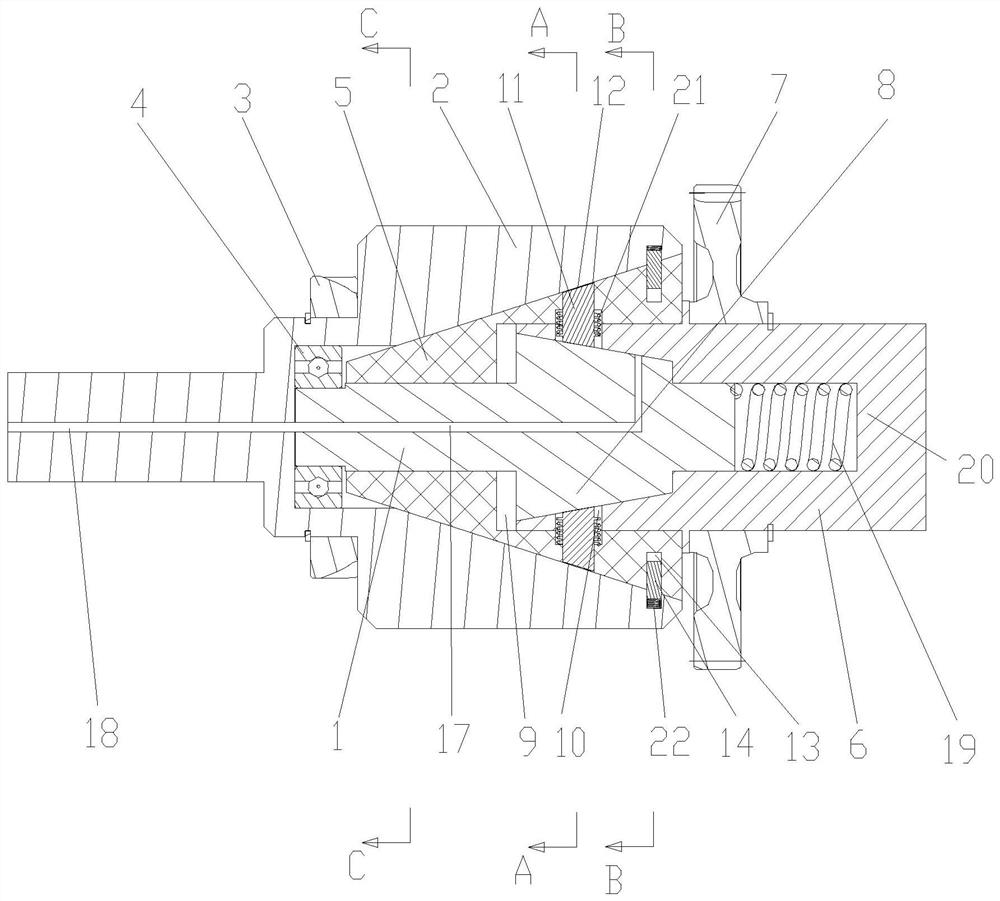

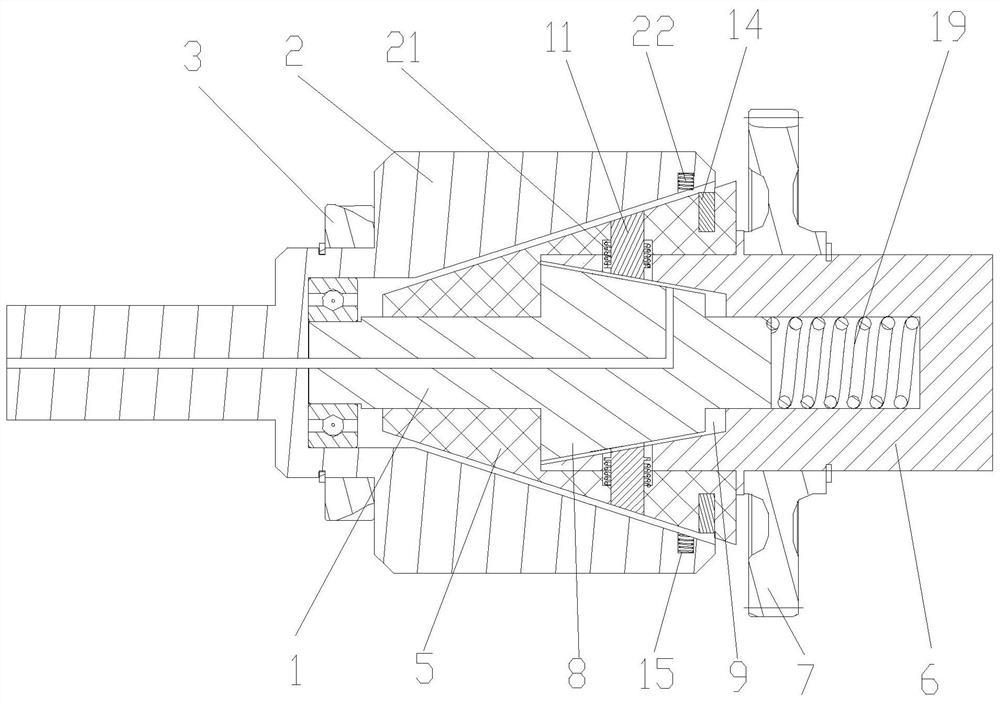

[0031] see Figure 1 to Figure 6 , the present embodiment discloses an engine driving device, including an active part and a passive part.

[0032] The driving part includes a driving shaft 1, a driving sleeve 2, and a driving wheel 3, and the axis direction of the driving shaft 1 is set as a left-right direction. The driving shaft sleeve 2 is rotatably fitted on the driving shaft 1, and the driving wheel 3 is fixedly sleeved on the left end of the driving shaft sleeve 2, and the inner hole of the driving shaft sleeve 2 is a tapered inner hole which is small on the left and large on the right. Wherein, the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com