Leakage plugging method for multi-layer casing damage section of oil well

A plugging method and oil well technology, which is applied in the direction of earthwork drilling, wellbore/well components, sealing/isolation, etc., which can solve the problem of long operation period, intubation that cannot ensure smooth insertion of bridge plugs, and inability to perform casing leveling. push process and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

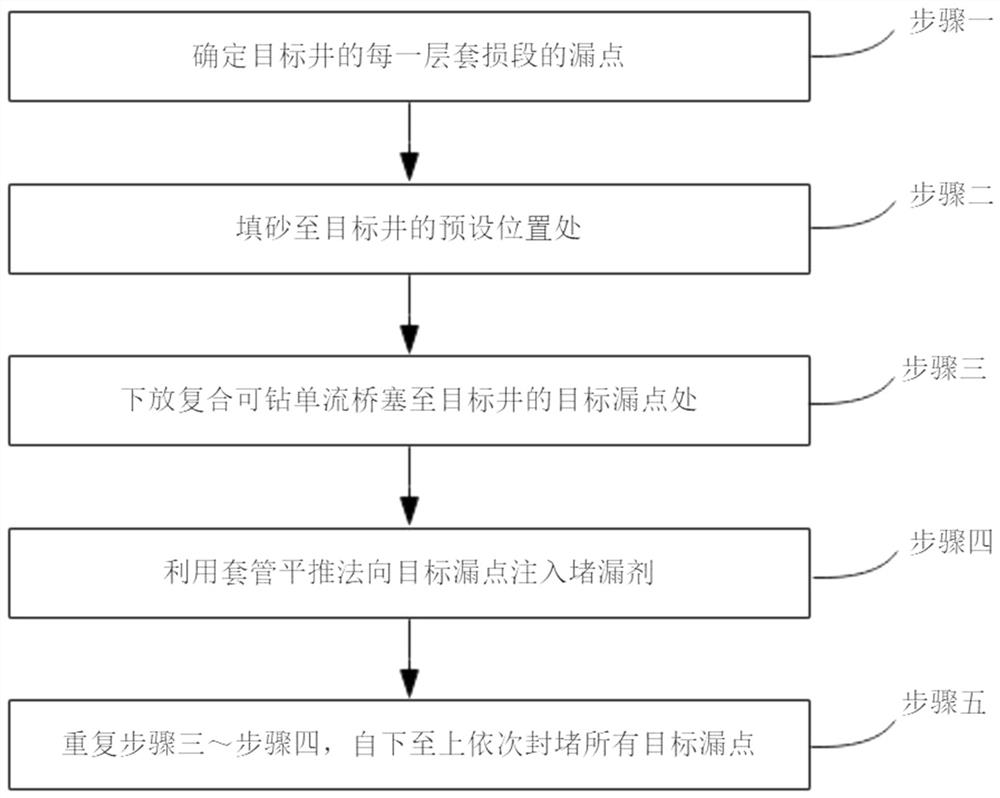

[0051] The first embodiment of the present invention relates to a plugging method for a multi-layer casing damaged section of an oil well, comprising the following steps:

[0052] Step 1, determining the leakage point of each casing damage section of the target well;

[0053] Step 2, filling sand to the preset position of the target well;

[0054] Step 3, lowering the composite drillable single-flow bridge plug to the target leakage point of the target well;

[0055] Step 4: Inject the plugging agent into the target leak point by using the casing horizontal push method;

[0056] Step 5, repeat steps 3 to 4, and block all target leaks sequentially from bottom to top.

[0057] According to the plugging direction from bottom to top, the casing damage section of each layer is plugged sequentially. According to the time sequence, the composite drillable single-flow bridge plugs installed are sequentially numbered as the first composite drillable single-flow bridge plug, and the s...

no. 2 approach

[0062] This embodiment relates to a plugging method for a multi-layer casing damage section of an oil well, including the following steps:

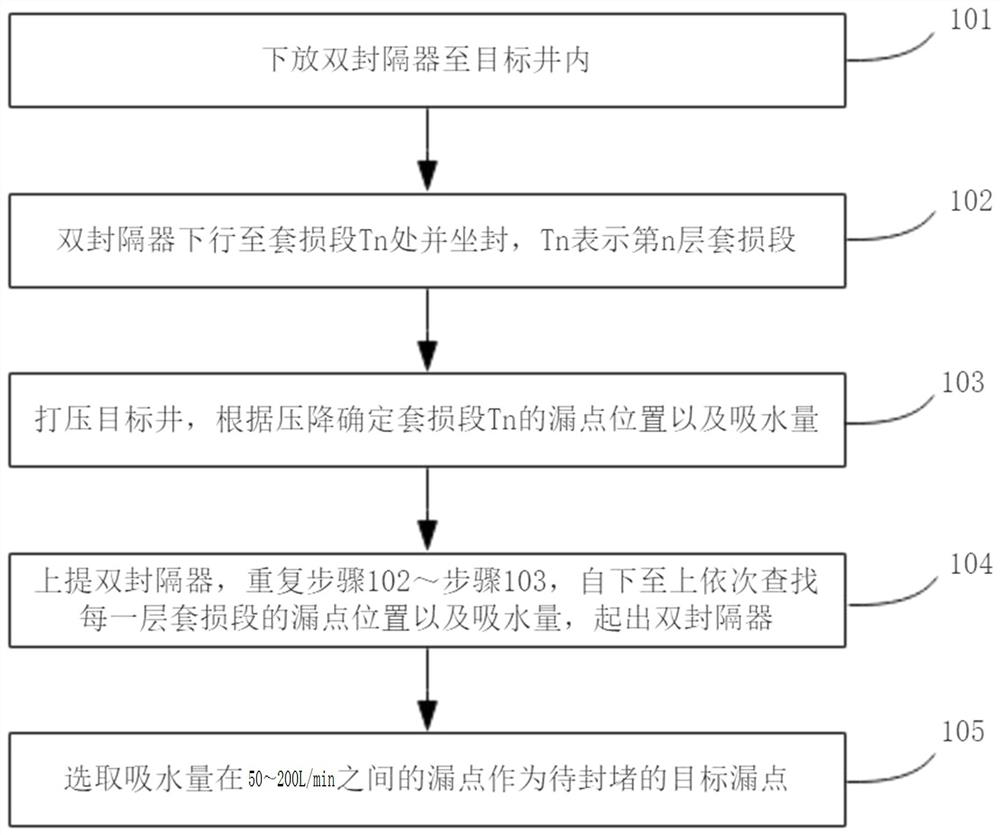

[0063] Step 1, determine the leakage point of each casing damage section of the target well, see figure 2 , including:

[0064] Step 101. lowering the double packer into the target well;

[0065] Step 102. The double packer goes down to the casing damage section Tn and sets, where Tn represents the casing damage section of the nth layer;

[0066] Step 103. Depress the target well, and determine the location of the leakage point and the water absorption of the casing damage section Tn according to the pressure drop;

[0067] Step 104. Lift up the double packer, repeat steps 102 to 103, search for the leakage point location and water absorption of each casing damage section from bottom to top, and pull out the double packer after the search is completed;

[0068] Step 105. Select a leak with a water absorption of 50-200 L / min as the tar...

no. 3 approach

[0095] In this embodiment, the following two wells have been tested using the plugging method of the multi-layer casing damage section of the oil well, specifically as follows:

[0096] The leak plugging operation was carried out in Well Luo X, which had 3 sections of casing damage after engineering logging.

[0097] The plugging resin plugging system is an epoxy resin plugging system, including E44 epoxy resin, triethylenediamine, and urotropine, and the three ratios are 100:12:1.

[0098] The plugging operation of the well is carried out, and the process is as follows:

[0099] Step 1: Double seal to confirm the leakage point and water absorption of each section;

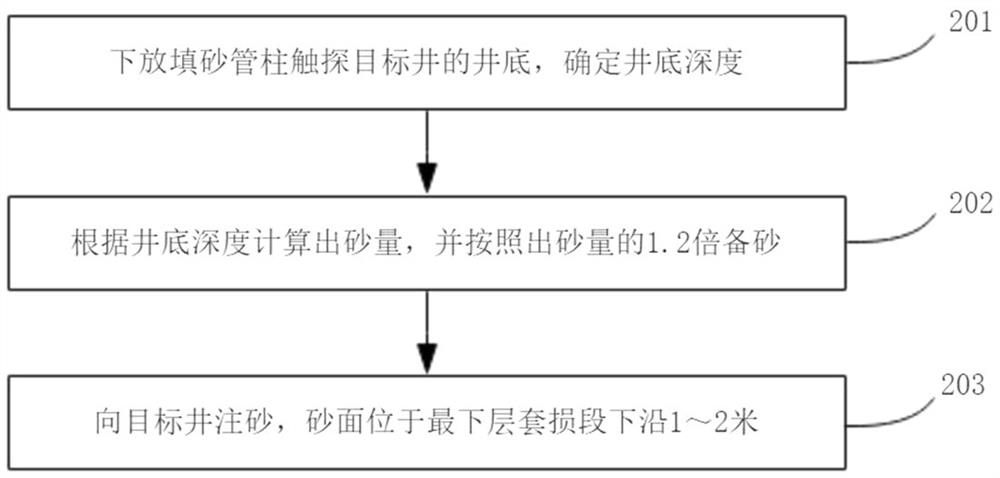

[0100] Step 2: Fill sand, the sand surface is located 1 meter below the lower edge of the casing damage section at the lowest end;

[0101] Step 3: Run the composite drillable single-flow bridge plug through the oil pipe operation, the lower edge of the bridge plug is located 1 meter above the upper edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com