Prefabricated external wall panel waterproof assembly structure and assembly process thereof

A technology of prefabricated wall panels and assembly structures, which is applied in the direction of building components, building structures, building insulation materials, etc., can solve the problems of inability to achieve a good waterproof effect and the decline in the effective load bearing capacity of prefabricated exterior walls, and achieve increased waterproofing , Increase the effect of waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

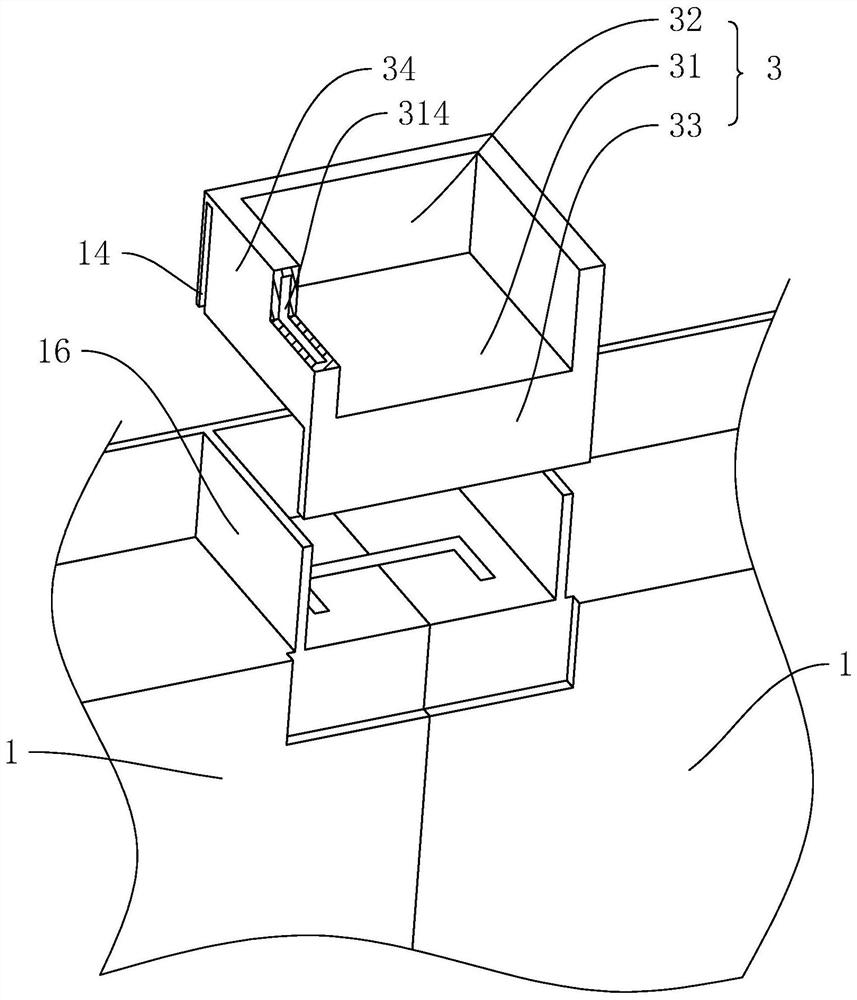

[0038] The application will be described in further detail below in conjunction with the accompanying drawings.

[0039] A prefabricated exterior wall panel waterproof assembly structure disclosed in the present application is used to increase the waterproof effect between adjacent prefabricated wall panels 1 on the same horizontal plane.

[0040] Such as figure 1 and figure 2 As shown, it includes a prefabricated wall panel 1 and a water retaining member 2 arranged between adjacent prefabricated wall panels 1 on the same horizontal plane. The side walls of the prefabricated wall panels 1 close to the adjacent prefabricated wall panels 1 are provided with vertically arranged Water retaining groove 11, water retaining groove 11 runs through the upper and lower end surfaces of prefabricated wall panel 1, and water retaining member 2 is arranged vertically, which is inserted in the water retaining groove 11 of adjacent prefabricated wall panel 1 at the same time. At this time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com