Treatment method for sliding of high slope of fragmented bulk solid on surface layer of deep-layer strong-dumping deformation body

A deformation body and slope technology, applied in excavation, construction, infrastructure engineering, etc., can solve the problems of weak foundation deformation, long construction period, and high safety risks, to prevent shallow sliding, shorten construction time, and reduce safety. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below.

[0038] After the initial landslide on the slope, there may be safety risks of multiple consecutive landslides in the follow-up. The emergency plan for slope landslides should be activated on the site in time, people in the dangerous area should be evacuated in time, warning signs should be set up, and traffic control should be implemented. On the premise of ensuring safety, organize professional technical personnel to investigate and understand the engineering geological conditions of the slope, the slope landslide situation and the slope support situation around the landslide body, etc., and make a preliminary judgment on the stability of the slope. Treat according to the method of the present invention again.

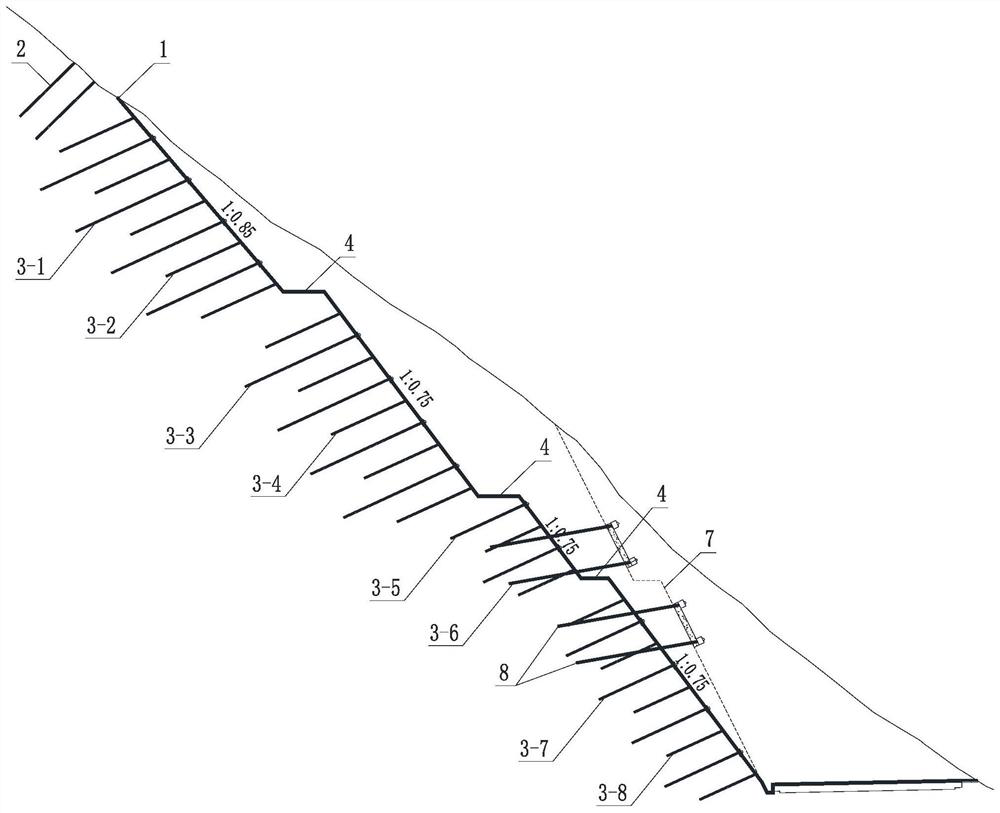

[0039] The treatment method of the present invention for the slump of a high slope with a deep layer of strong toppling deformed body, the surface layer of which is fragmented and scattered, comprises th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com