Thick mash yellow rice wine fermentation process

A fermentation process and rice wine technology, which is applied in the field of fermented rice wine with thick mash, can solve the problems of large production water consumption, poor flavor of wine body, complicated procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

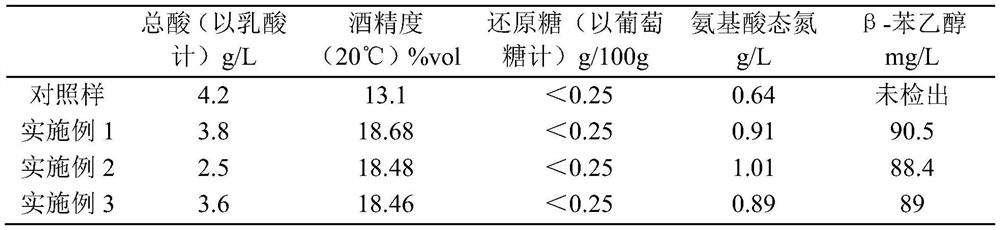

Embodiment 1

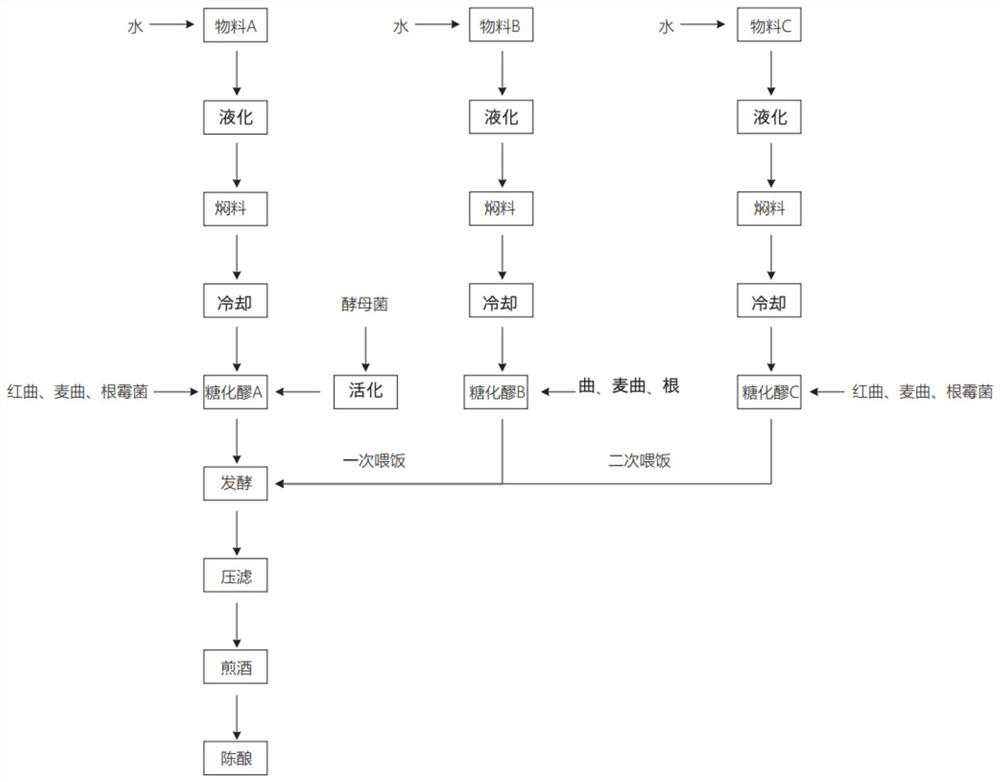

[0030] S1. The material A is made into mash A, the material B is made into mash B, and the material C is made into mash C.

[0031] After the glutinous rice (or rice) is checked and accepted, the dust, stones and other impurities contained in the glutinous rice are removed through a dust collector and a vibration sieve. The material after removing glutinous rice is divided into three parts, namely material A, material B and material C. The weight ratio of material A, material B and material C is 1:1:1.

[0032] The process of making the material A into a mash A comprises the following steps:

[0033] P1. Liquefaction: Take material A and water and put them into the liquefaction tank at a weight ratio of 1:1.8, then add α-amylase with a total weight of material A of 1‰, turn on the steam and start stirring, slowly raise the temperature to 94°C and maintain it for 1 hour to fully liquefaction.

[0034] P2. Stewing material: keep warm at 95°C for 0.5h, turn off the steam and s...

Embodiment 2

[0048] S1. The material A is made into mash A, the material B is made into mash B, and the material C is made into mash C.

[0049] After the glutinous rice is checked and accepted, the dust, stones and other impurities contained in the glutinous rice are removed by a dust collector and a vibration sieve. The material after removing glutinous rice is divided into three parts, namely material A, material B and material C. The weight ratio of material A, material B and material C is 1:0.8:1.2.

[0050] The process of making the material A into a mash A comprises the following steps:

[0051] P1. Liquefaction: Take material A and water and put them into the liquefaction tank at a weight ratio of 1:1.9, then add α-amylase with a total weight of 0.5‰ of material A, turn on the steam and start stirring, slowly raise the temperature to 85°C and maintain it for 1.2h to make it fully liquefied.

[0052] P2. Stewing material: keep warm at 96°C for 0.6h, turn off the steam and stew th...

Embodiment 3

[0066] S1. The material A is made into mash A, the material B is made into mash B, and the material C is made into mash C.

[0067] After the glutinous rice is checked and accepted, the dust, stones and other impurities contained in the glutinous rice are removed by a dust collector and a vibration sieve. The material after removing glutinous rice is divided into three parts, namely material A, material B and material C. The weight ratio of material A, material B and material C is 1:1.2:0.8.

[0068] The process of making the material A into a mash A comprises the following steps:

[0069] P1. Liquefaction: Take material A and water into the liquefaction tank at a weight ratio of 1:2, then add α-amylase with a total weight of 1.5‰ of material A, turn on the steam and start stirring, slowly raise the temperature to 90°C and maintain it for 0.8h to make it fully liquefied.

[0070] P2. Stewing material: keep warm at 98°C for 0.4h, turn off the steam and stew the material for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com