Feeding mechanical hand

A manipulator and material feeding technology, which is applied in the field of manipulators, can solve problems such as broken tiles, insufficient feeding, and waste of tiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

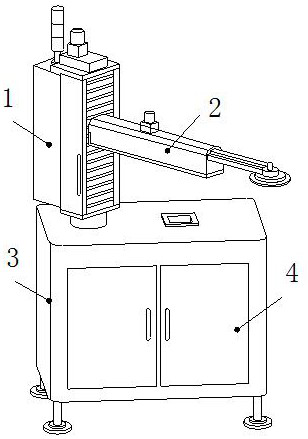

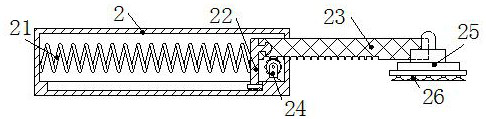

[0029] The invention provides a feeding manipulator, the structure of which includes a rotating column 1, a mechanical arm 2, a base 3, and a locker 4. The bottom of the rotating column 1 is movably engaged with the upper wall of the base 3, and the mechanical arm 2 is mounted One side of the rotating column 1, the front side of the base 3 is provided with a locker 4, and the mechanical arm 2 includes a telescopic spring 21, a positioning block 22, a telescopic rod 23, a runner 24, a grabbing head 25, and a suction block 26, The left end of the telescopic spring 21 is embedded in the left inner wall of the mechanical arm 2, the left side of the positioning block 22 is welded to the right end of the telescopic spring 21, and the bottom of the positioning block 22 is connected to the inner bottom of the mechanical arm 2 through a gap. The telescopic rod 23 The left end is embedded and fixed on the right side of the positioning block 22 and runs through the right wall of the mecha...

Embodiment 2

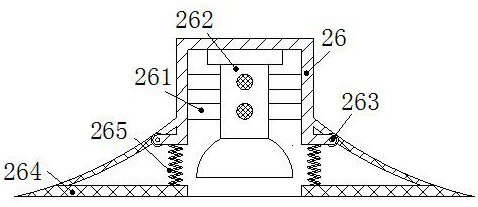

[0035] In the figure, the suction block 26 includes a fixed rod 261, a suction cup 262, a rotary block 263, a cleaning plate 264, and a limit spring 265. One end of the fixed rod 261 is welded to the inner wall of the suction block 26, and the suction cup 262 is embedded in the fixed At the other end of the rod 261, the turning block 263 is connected to the inner wall of the suction block 26 through bolts, the cleaning plate 264 is embedded in the bottom of the suction block 26, and the limiting spring 265 is welded between the limiting spring 265 and the turning block 263 , the bottom of the suction block 26 can rotate around the rotating block 263, and the elasticity of the limit spring 265 makes the cleaning plate 264 have elastic force, which is beneficial to squeeze the cleaning plate 264 to clean the tiles when sucking the tiles, so that the suction cup 262 can suck tile surface.

[0036]In the figure, the cleaning board 264 includes a sponge board b1, a brush b2, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com