Fitting system

A bonding system and a technology of pressing parts, applied in the field of bonding systems, can solve problems such as high cost of bonding trial and error, long time, affecting bonding quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described below with reference to the accompanying drawings in the embodiments of the present invention.

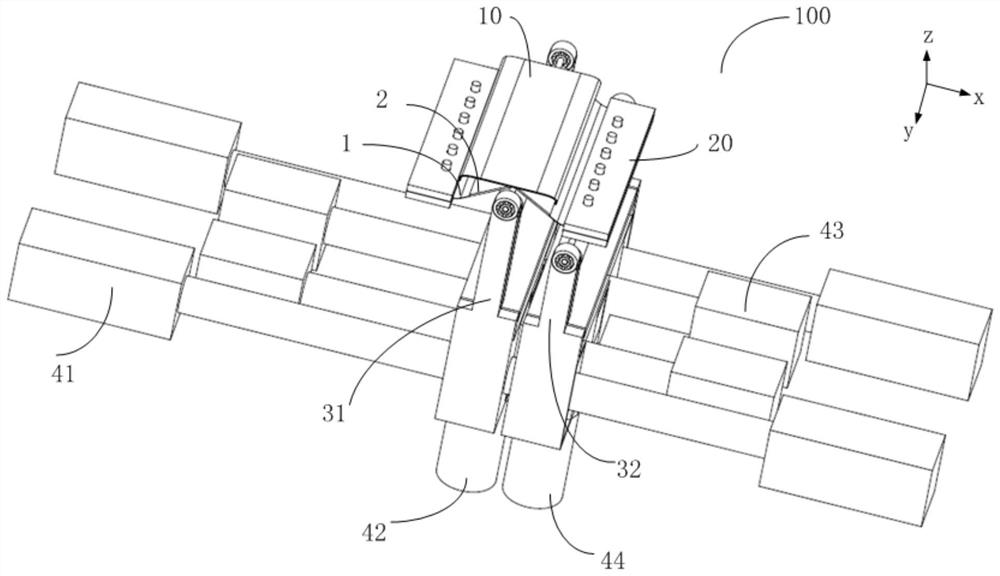

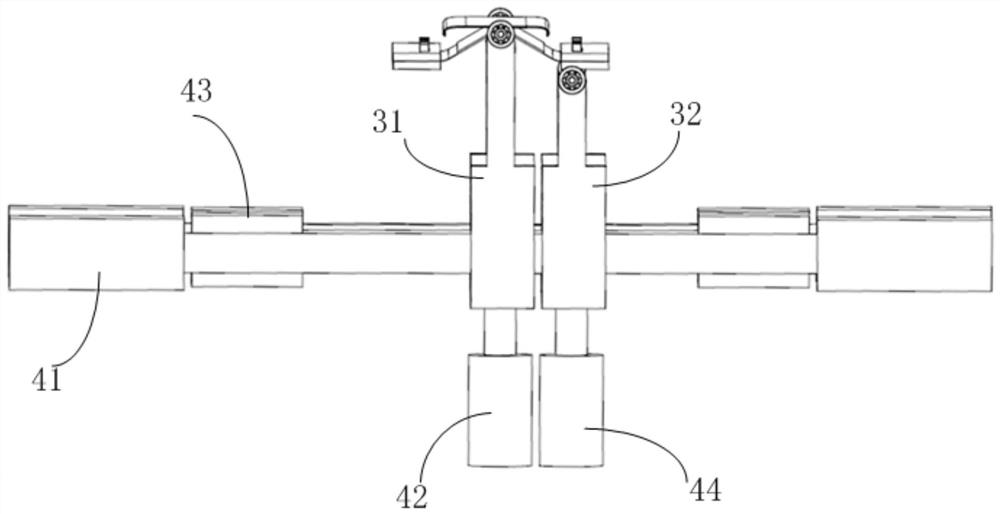

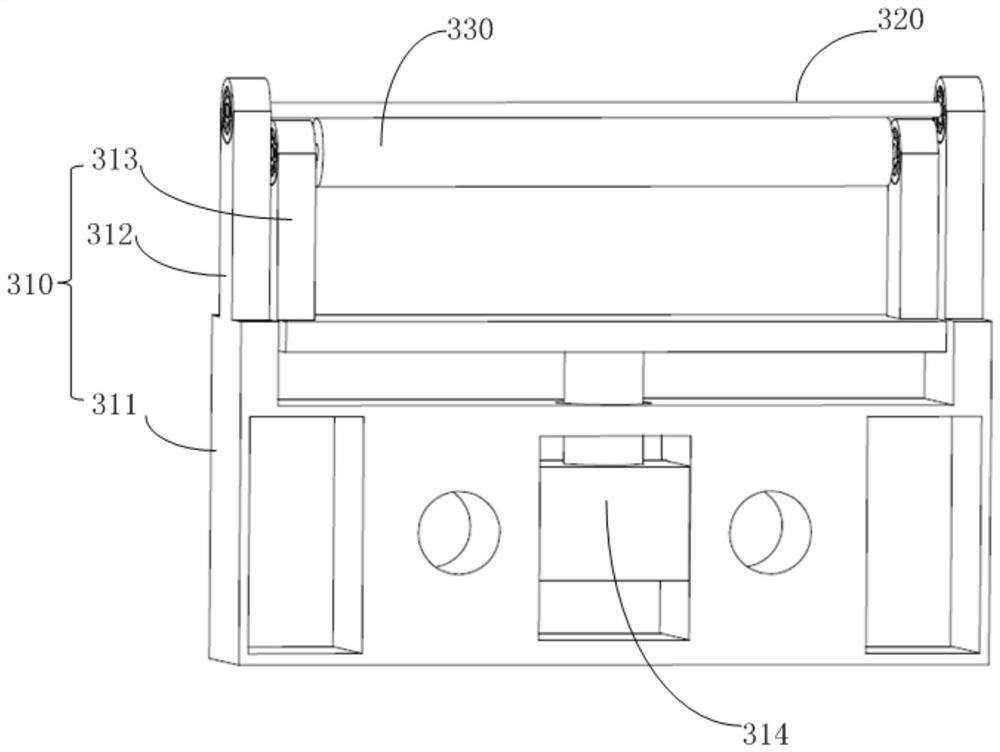

[0038] like figure 1 and figure 2As shown, the embodiment of the present invention provides a bonding system 100 for bonding a curved cover plate and a flexible film 2. The bonding system includes a cover plate fixing member, a roller pressing mechanism and a carrying film control mechanism; The cover plate fixing part 10 is used to fix the curved cover plate, and the curved cover plate includes a straight central area and arc edge areas on the opposite side edges; Parts 31, 32, and two groups of roller driving devices connected to the two roller pressing parts 31, 32 respectively, such as image 3 As shown, each of the roller pressing parts 31, 32 includes a fixed frame 310 and a first roller assembly 320 arranged on the fixed frame 310; each set of roller driving devices includes a horizontal displacement drivin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com