Welding machine management system and method for steel structure welding

A management system and welding machine technology, which is applied in the general control system, welding equipment, welding accessories, etc., can solve the problems that the welding machine workers and welding machines do not have a suitable management plan, so as to enhance the safe production environment, facilitate piece counting, strong retroactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

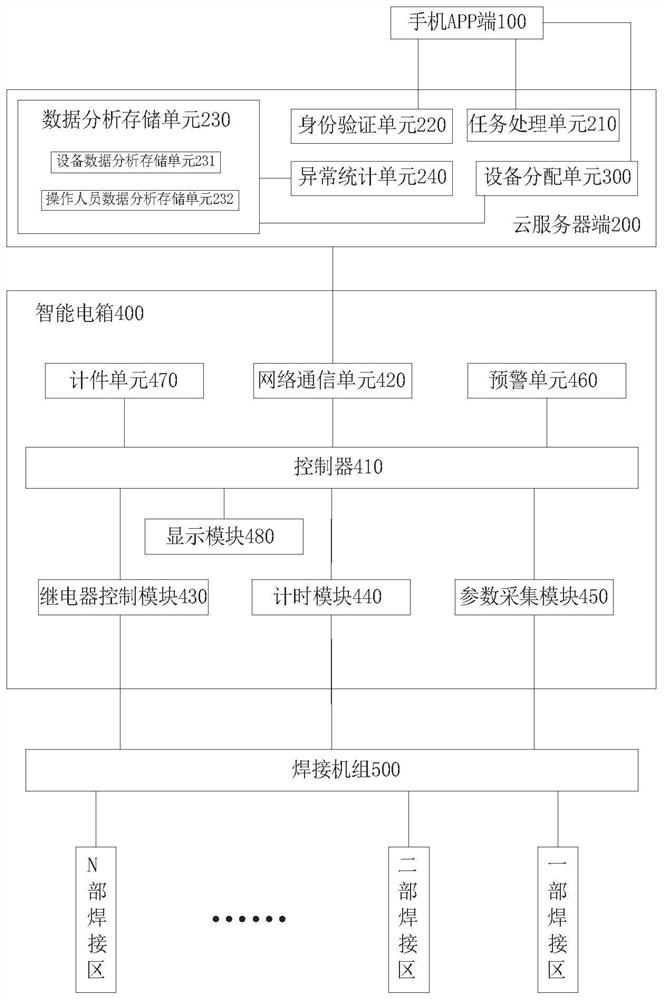

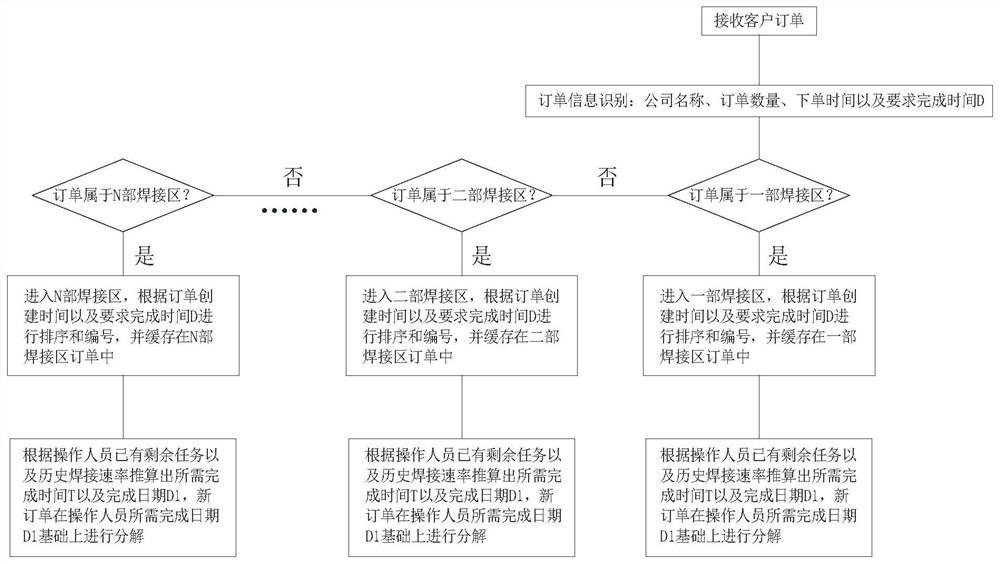

[0046] See figure 1 and figure 2 , the present invention includes a mobile phone APP terminal 100 for receiving tasks and identity verification, a cloud server terminal 200 communicating with the mobile terminal, a device allocation unit 300 for matching and adjusting between equipment and operators, uploading data information, and receiving The smart electric box 400 of the order and the welding group 500 that is made up of a plurality of welding zones; The APP end of the mobile phone establishes a communication connection with the cloud server end 200 through wireless communication; Each welding zone in the welding group 500 is composed of multiple electric welding The unit is composed of different welding zones and the corresponding welding tasks are different; the electrical signal interval of each electric welding machine includes a power-off interval, a standby interval, a working interval and an abnormal interval.

[0047] More specifically in this embodiment, the sma...

Embodiment 2

[0058] The difference between the present invention and Embodiment 1 is that when the electric welding machine is in the standby zone, the current value corresponding to the electric welding machine is about 1 / 10 of the working current, the voltage value is 380V, and the output power is 1 / 10 of the output power during operation. / 10 or so;

[0059] When the electric welding machine is in the working range, the current value corresponding to the electric welding machine is 50-300A, the voltage value is 380V, and the output power is 10KW-50KW;

[0060] When the electric welding machine is in the abnormal interval, the corresponding current value of the electric welding machine is greater than 300A, the voltage value is 380V, and the output power is greater than 50KW.

Embodiment 3

[0062] On the basis of Embodiment 1, the present invention optimizes that the smart electric box 400 further includes a piece counting unit 470 ; the piece counting unit 470 is connected to the controller 410 .

[0063] More specifically in this embodiment, the piece counting unit 470 is a weighing and piece counting unit, which can calculate the number of welds completed by the operator according to the weight of a single piece of weldment that is initialized in the system; for weldments with the same specification, that is The operator can divide the total weight of the welded parts by the weight of a single piece of welded parts from the start of the machine to the end of the machine, and can count the pieces by superimposing the single pieces to obtain the number of welded parts and directly input them into the cloud server 200 through the controller 410 ; For weldments with different specifications, the pieces are counted directly by superposition of single pieces: For examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com