Camera module dispensing system based on turntable

A camera module and glue dispensing technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems that the glue dispensing path cannot be corrected immediately and in real time, and it is difficult to correct the glue dispensing path in real time, so as to achieve the goal of eliminating Noise, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

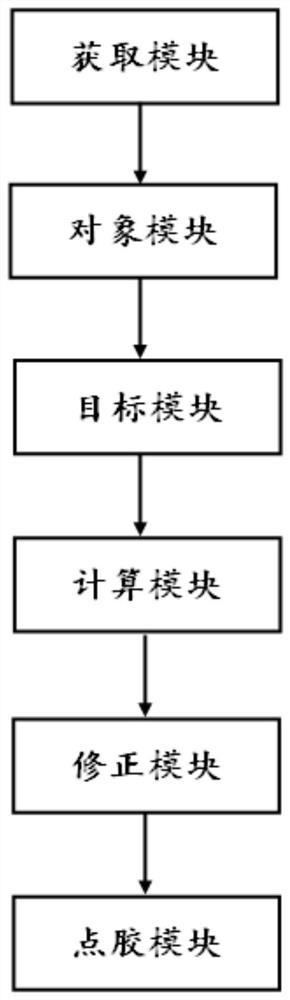

[0047] The embodiment of the camera module dispensing system based on the turntable of the present invention is basically as attached figure 1 shown, including:

[0048] The acquisition module is used to obtain dispensing path information according to the preset dispensing path;

[0049] The object module is used to obtain the object image coordinates of the object marking point in real time, the object marking point is located on the dispensing object, and the object image coordinates are the coordinates of the object marking point under the image coordinate system of the visual positioning camera;

[0050] The target module is used to obtain the target image coordinates of the target marking point in real time, the target marking point is located on the dispensing platform, and the target image coordinates are the coordinates of the target marking point under the image coordinate system of the visual positioning camera;

[0051] The calculation module is used to calculate t...

Embodiment 2

[0067] The only difference from Embodiment 1 is that the correction module further includes a filtering unit for filtering the dispensing path according to the second position information and the position information of the determined nodes. Specifically, the first step is to connect the point corresponding to the first position information of the undetermined node and the nearest definite node of the undetermined node into a first straight line according to the preset filter multiplier value, and fit the definite node into a second straight line . The second step is to calculate the angle between the first straight line and the second straight line, and increase the filter multiplier value when the angle is greater than the angle threshold. For example, calculating the angle between the first straight line and the second straight line includes: converting the position information of the determined node and the first position information of the undetermined node into Cartesian...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com