Outdoor low-voltage enclosed load isolation switch

An isolating switch and closed technology, which is applied in the field of outdoor low-voltage closed load isolating switches, can solve problems such as ineffective protection of lines and equipment, potential safety hazards of maintenance lines, and damage to knives or contacts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

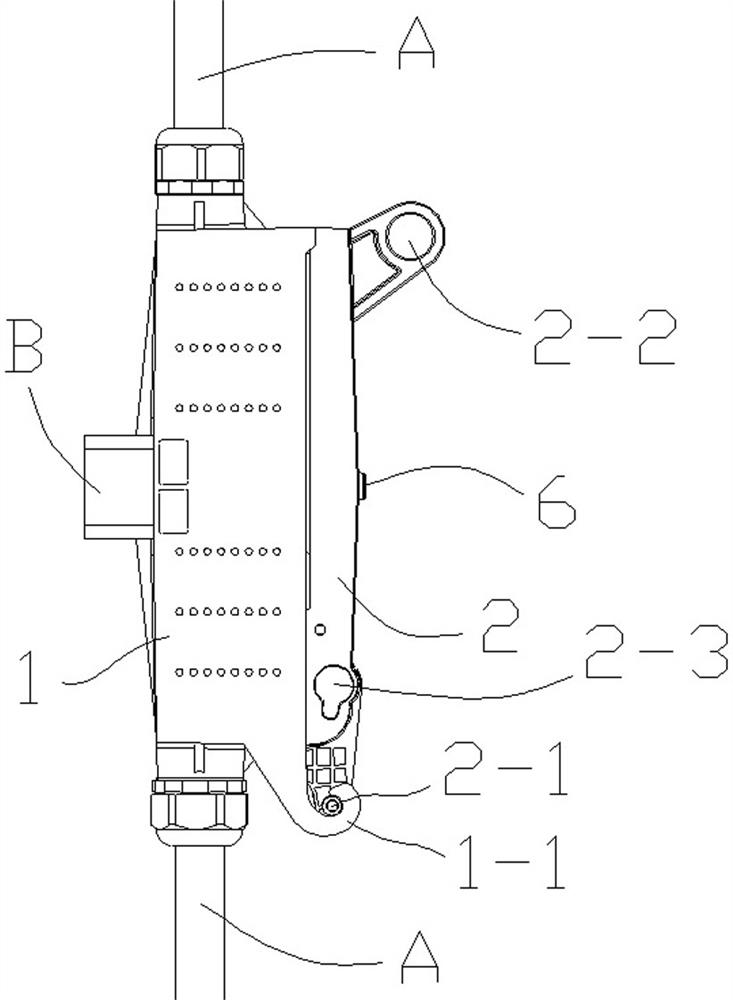

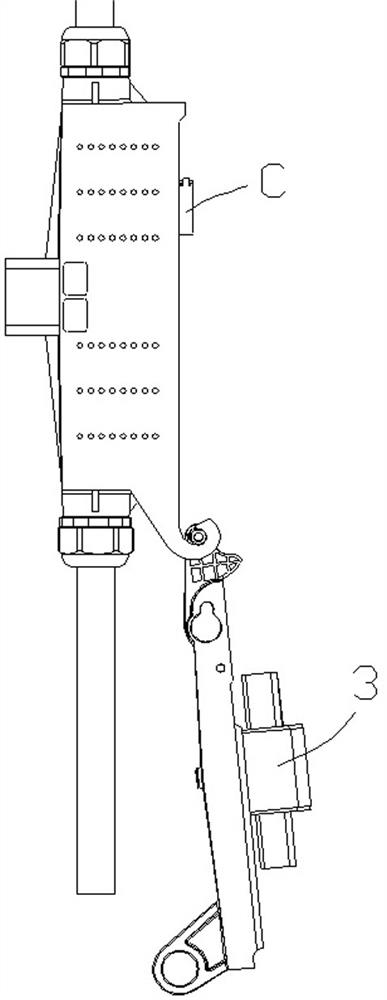

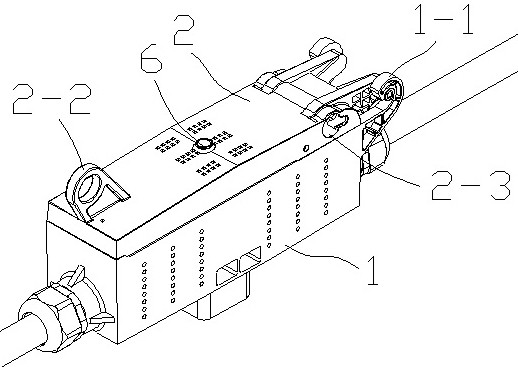

[0028] An outdoor low-voltage enclosed load isolating switch is structured as follows: the outdoor low-voltage enclosed load isolating switch is composed of a box body 1, a cover body 2, a fuse 3, two connection terminals 4 and two static contacts 5;

[0029] The fuse 3 is a knife-shaped fuse; the outer wall of the middle of the fuse 3 is connected to the inner side of the cover body 2;

[0030] The static contacts 5 are arranged on the bottom surface of the inner cavity of the box body 1 , and the positions of the two static contacts 5 are in one-to-one correspondence with the two contact blades on the fuse 3 ; the connection terminals 4 are arranged in the box body 1 . On the bottom surface of the cavity, the two terminals 4 are isolated from each other; the terminal 4 includes a contact connection end and a wire connection end, the contact connection end is electrically connected with the static contact 5, and the two connection terminals 4 are connected with the two static ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com