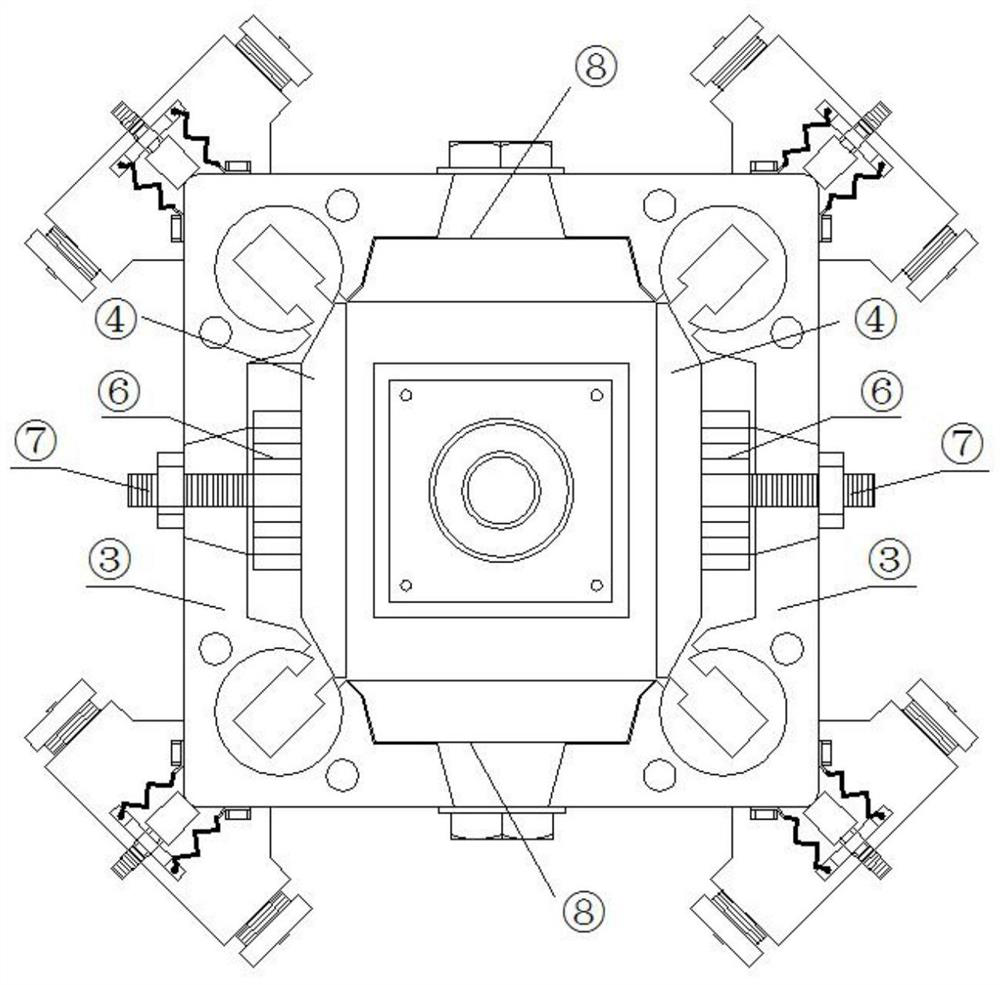

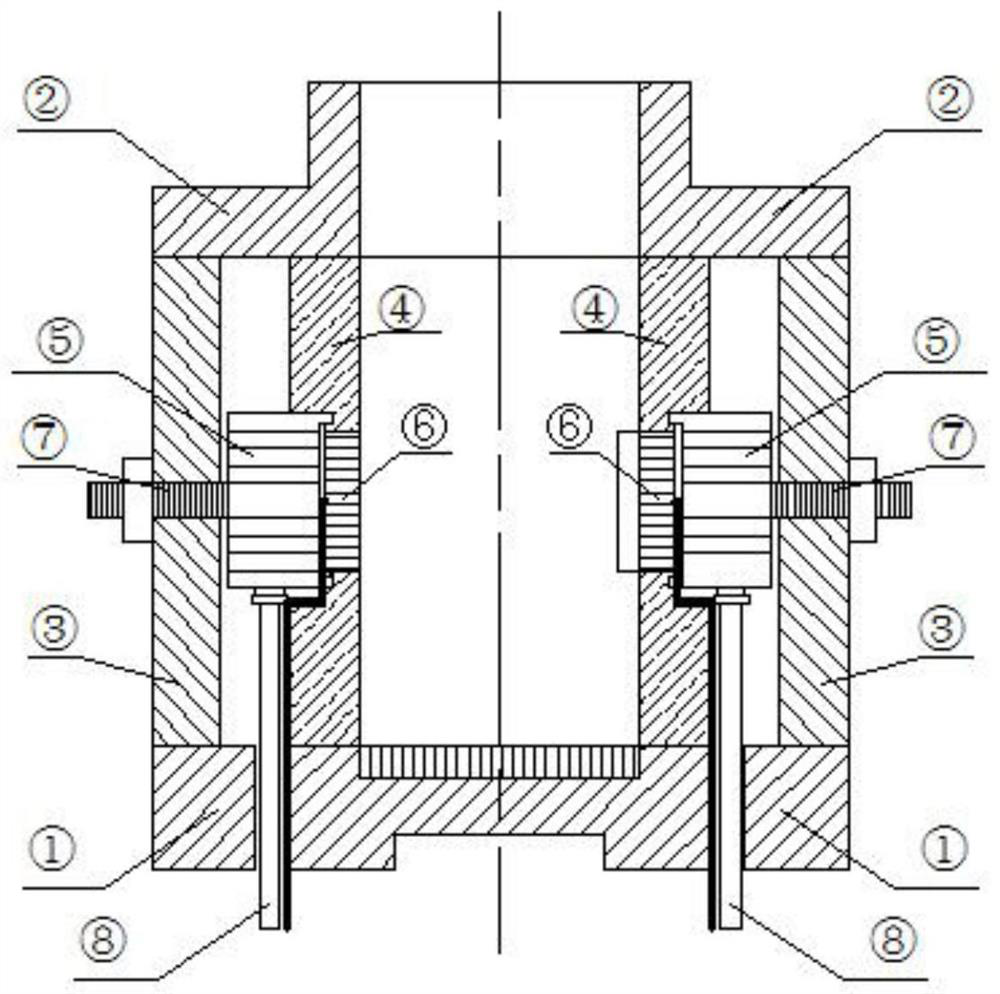

Automatic loading and unloading hydraulic plane strain test device

A plane strain and testing device technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems that the main stress adjustment depends on manual labor and the accuracy is difficult to ensure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

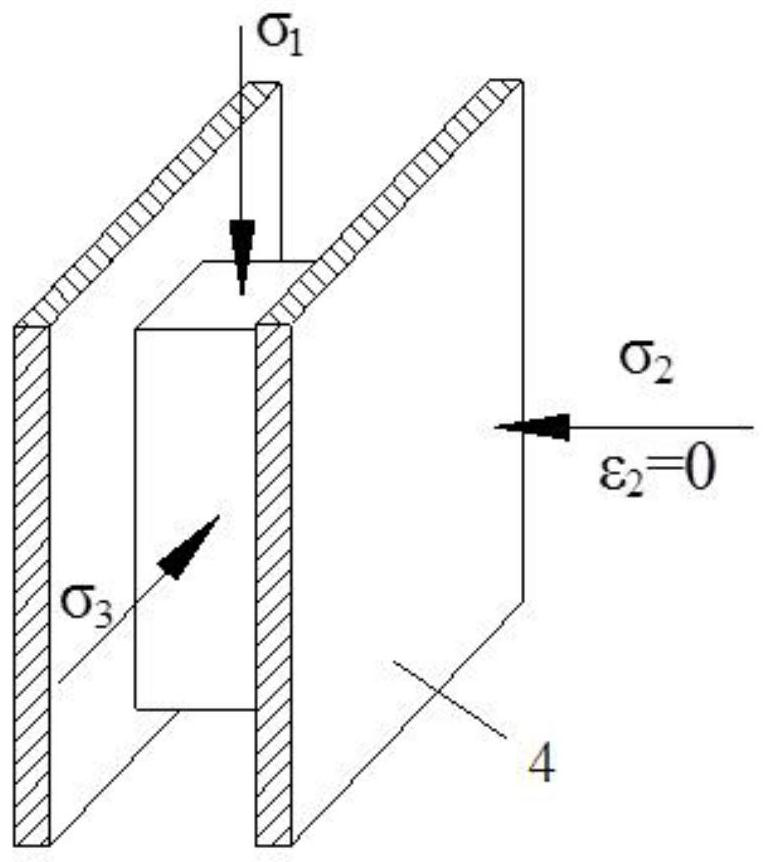

[0044] Put the soil to be tested into the plane stress strain chamber surrounded by the baffle 4 and the hydraulic bladder 8, open a hole in the center of the two symmetrical baffles 4 and insert a steel string type earth pressure cell 6 in each. After the sample is installed, in the pressure chamber 3 in the plane strain direction, the hydraulic ultra-thin jack 5 is rotated and fixed on the pressure chamber through the M10 loading bolt 7 with a length of 40mm, and two pairs of concave smooth rigid baffles 4 are placed vertically. And the two wings of the jack 5 are embedded in the groove on the back of the smooth rigid baffle plate 4 to fix the hydraulic ultra-thin jack 5. The method of applying confining pressure in the direction of the small principal stress is consistent with the operation of the existing true triaxial instrument; cover the top cover of the pressure chamber 2. Push the hydraulic ultra-thin jack 5 to elongate through computer operation, so that the smooth ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com