Bearing retainer convenient to disassemble and assemble

A technology for easy disassembly and assembly of bearing cages, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., and can solve problems such as difficult removal of bearing cages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

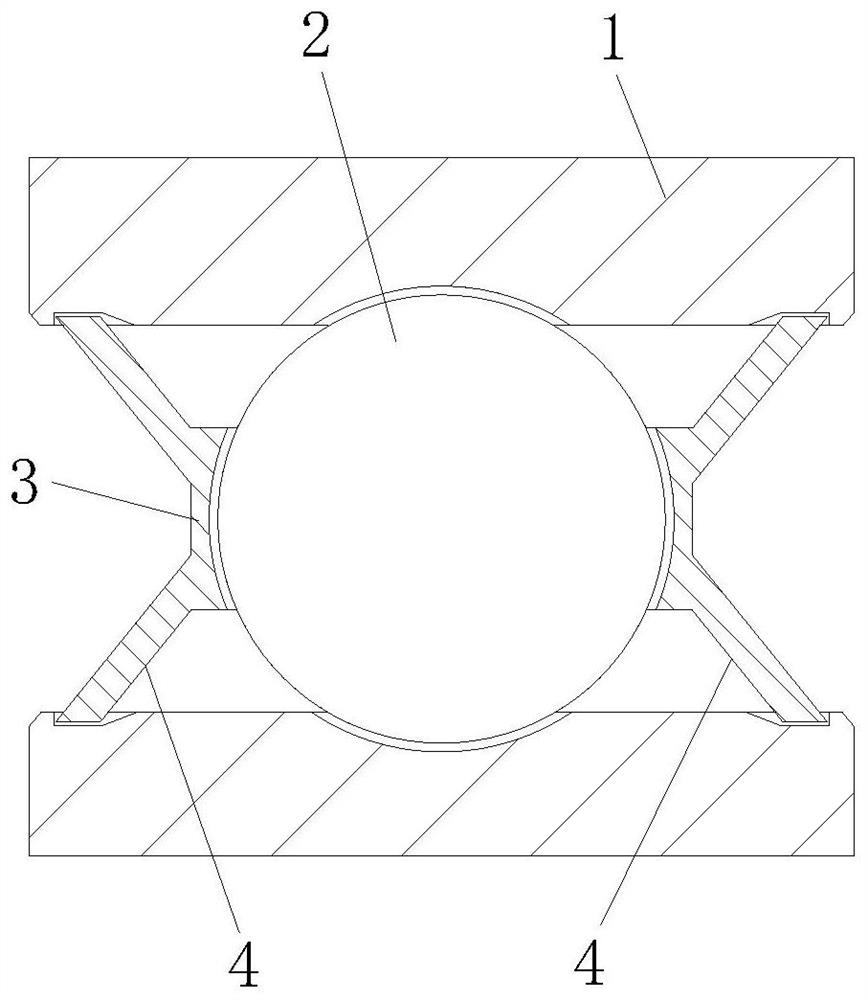

[0028] Example 1, please refer to Figure 1~3 , a bearing cage that is easy to disassemble and assemble, including a cage body 3 that surrounds the balls 2 laterally, and a flying plate 4 that reaches the shaft frame 1 is integrally formed on the cage body 3, and the flying plate 4 is used as a plugging shaft frame 1 and The sealing setting between the balls 2 is used to prevent foreign matter such as dust from entering the balls 2 and affecting the normal rotation of the balls 2, thereby affecting the overall service life of the bearing. Considering the friction between the fly plate 4 and the axle frame 1, Therefore, it is recommended that the flying plate 4 be made of nitrile rubber, and be fixed with the metal cage body 3 by embossing. The cage body 3 is provided with an arc-shaped groove 5 at the position close to the ball 2 for contact with the ball 2. Close to each other to facilitate the rolling of the ball 2;

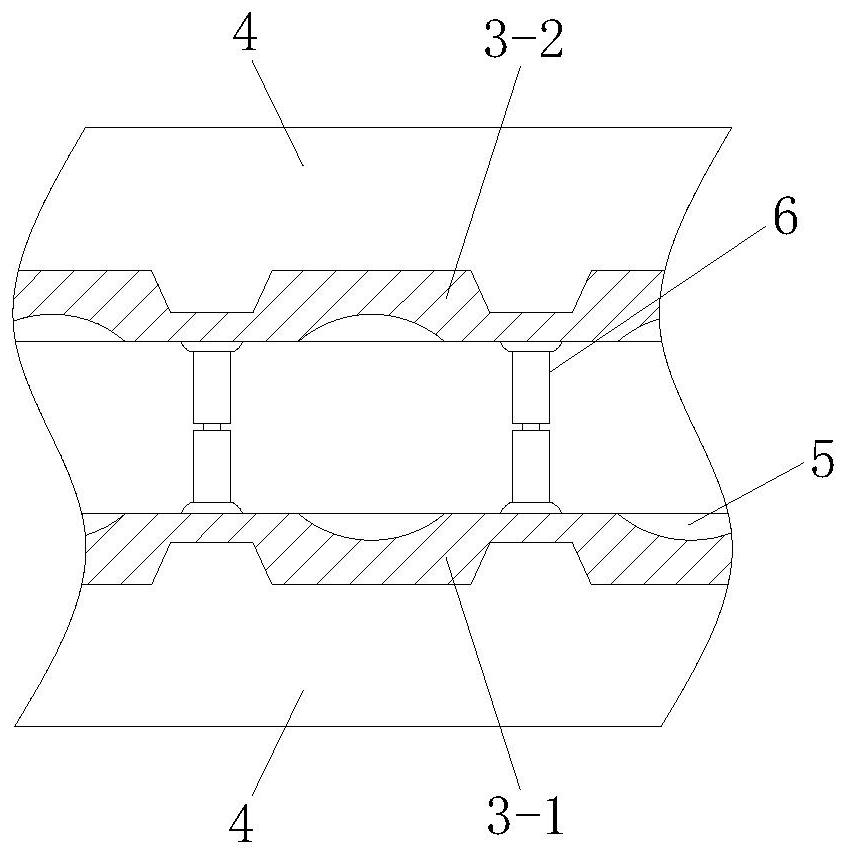

[0029] The cage body 3 includes a front frame body 3-1 a...

Embodiment 2

[0030] Example 2, please refer to Figure 1~4 , a bearing cage that is easy to disassemble and assemble, including a cage body 3 that surrounds the balls 2 laterally, and a flying plate 4 that reaches the shaft frame 1 is integrally formed on the cage body 3, and the flying plate 4 is used as a plugging shaft frame 1 and The sealing setting between the balls 2 is used to prevent foreign matter such as dust from entering the balls 2 and affecting the normal rotation of the balls 2, thereby affecting the overall service life of the bearing. Considering the friction between the fly plate 4 and the axle frame 1, Therefore, it is recommended that the flying plate 4 be made of nitrile rubber, and be fixed with the metal cage body 3 by embossing. The cage body 3 is provided with an arc-shaped groove 5 at the position close to the ball 2 for contact with the ball 2. Close to each other to facilitate the rolling of the ball 2;

[0031] The cage body 3 includes a front frame body 3-1 a...

Embodiment 3

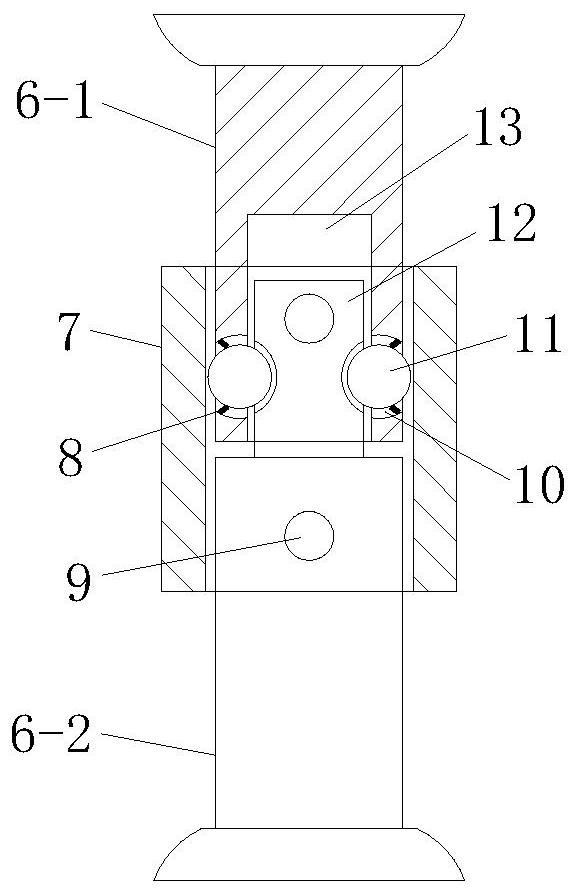

[0034] Embodiment three, please refer to Figure 1~2 and 5-6, a bearing cage that is easy to disassemble and assemble, including a cage body 3 that surrounds the balls 2 laterally, and a flying plate 4 that reaches the shaft frame 1 is integrally formed on the cage body 3, and the flying plate 4 is used as a plug The seal between the shaft frame 1 and the ball 2 is used to prevent foreign matter such as dust from entering the ball 2 and affecting the normal rotation of the ball 2, thereby affecting the overall service life of the bearing. Considering the fly plate 4 and the shaft frame 1 friction, so the flying plate 4 is recommended to be made of nitrile rubber, which is fixed with the metal cage body 3 by embossing. The cage body 3 is provided with an arc-shaped groove 5 at the position close to the ball 2. Because it is close to the ball 2, it is convenient for the ball 2 to roll;

[0035] The cage body 3 includes a front frame body 3-1 and a rear frame body 3-2 located on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com