Centrifugal water pump

A centrifugal and water pump technology, applied in the field of centrifugal pumps, can solve problems such as high cost, affecting pump efficiency, and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

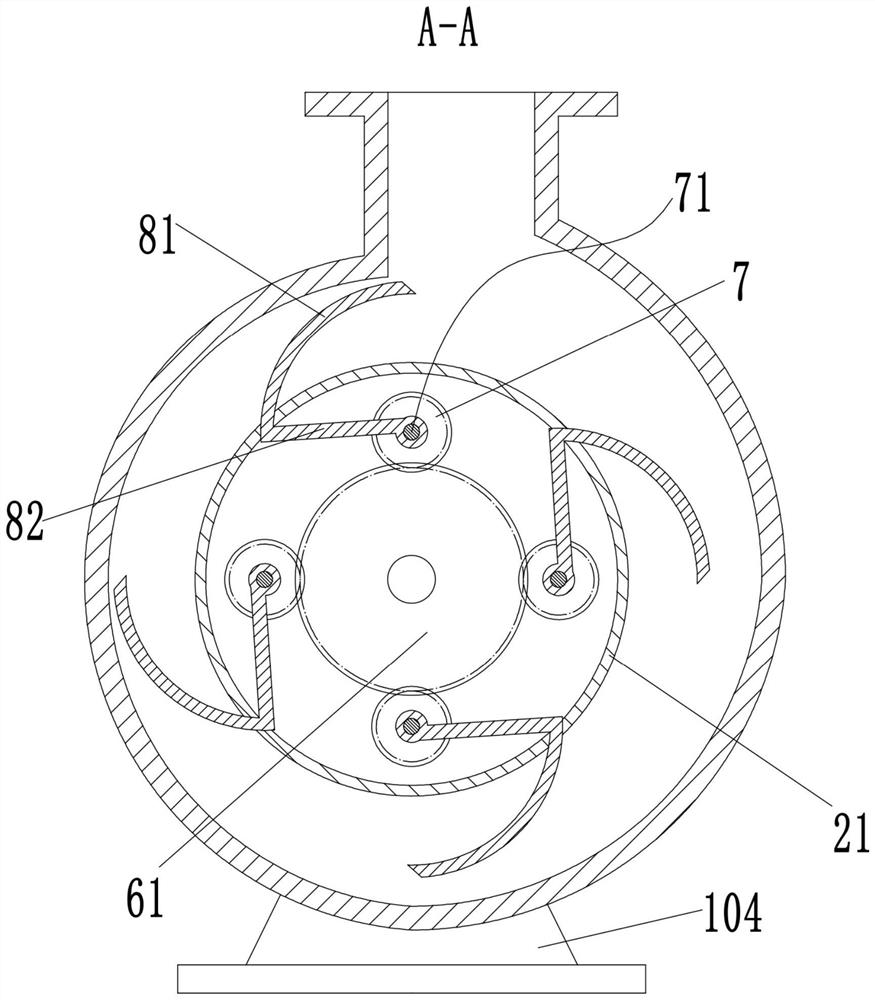

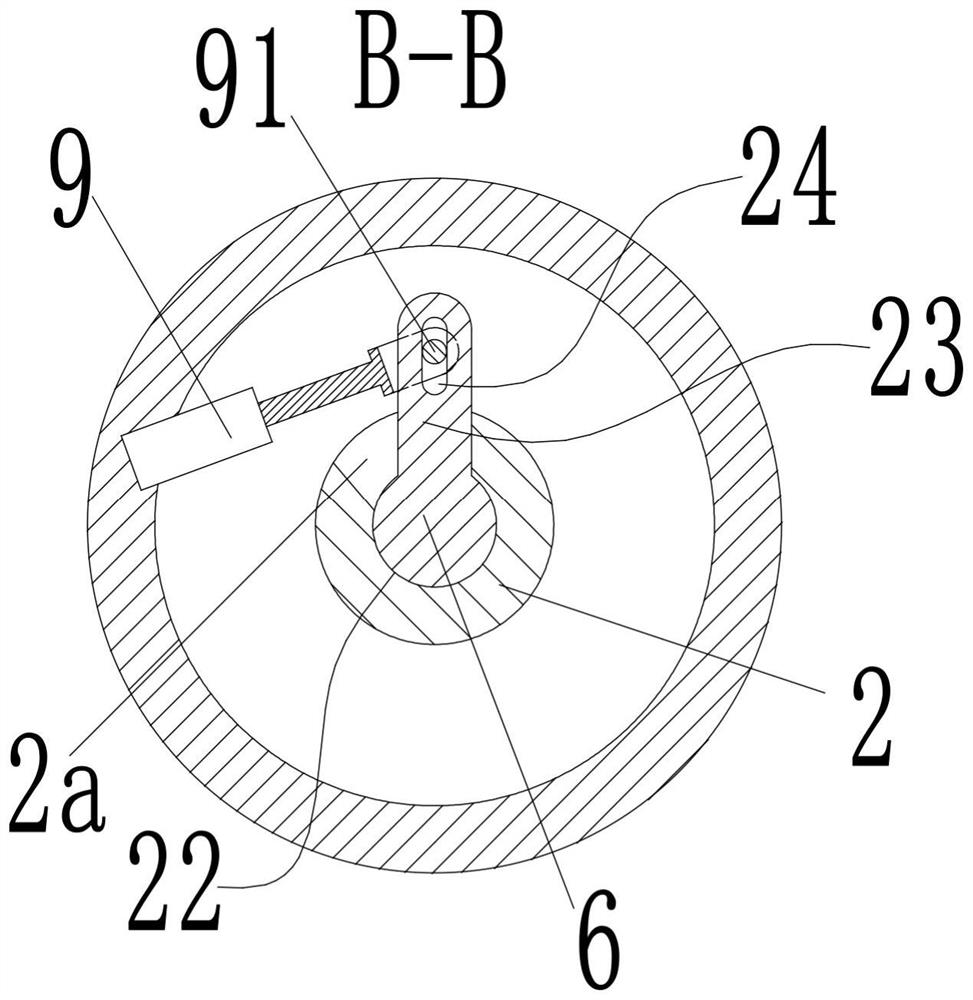

[0019] see Figure 1-5 As shown, a centrifugal water pump includes a pump body 1, a pump chamber 101 is arranged inside the pump body 1, and a pump cover 3 is fixedly installed at the opening of the right end of the pump chamber 101, and the pump cover 3 is rotatably connected to There is a power shaft 2 whose left end extends into the pump cavity 101, the side of the pump body 1 is provided with a water inlet pipe 102 along the axial direction of the power shaft 2, and a water outlet pipe 103 is provided along a direction perpendicular to the power shaft 2; The left end of the power shaft 2 is provided with a wheel housing 21 with a left end opening, and the left end of the power shaft 2 in the wheel housing 21 is provided with a shaft hole 22, and the shaft hole 22 is rotationally connected with a shaft rod 6, and the shaft rod 6 The left end is provided with a gear plate 61 located in the wheel housing 21; the opening of the left end of the wheel housing 21 is fixedly equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com