Tide type sand laying fracturing method

A tidal and sand-laying technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of shortening the effective fracture length, easily clogging reservoir pores, and residue particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

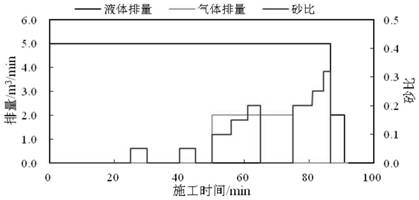

Embodiment 1

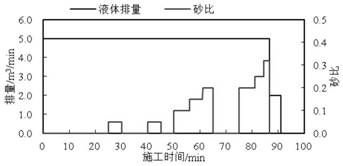

[0050] Use 2% concentration of active water fracturing fluid (that is, 2% concentration of KCl solution), and use N as the gas 2 , fracturing fluid displacement 5m 3 / min, the ceramsite proppant of 100 mesh (0.149mm) and 30 / 60 mesh (average particle size 0.324mm) is selected as the proppant, and the liquid is pumped continuously, but the gas and proppant are pumped discontinuously. Using the wave effect of liquid slug and discontinuous fluid, the proppant deposited around the fracture entrance is tidally propelled into the fracture in a timely manner, increasing the effective length of the fracture, and freeing up more space for the subsequent entry of proppant, thus It can not only reduce the risk of sand plugging, but also significantly increase the overall sand addition in fracturing construction, and improve the long-term conductivity of fractures. The fracturing pumping procedure is as follows: figure 2 , the indoor test results are as follows image 3 shown.

[0051]...

Embodiment 2

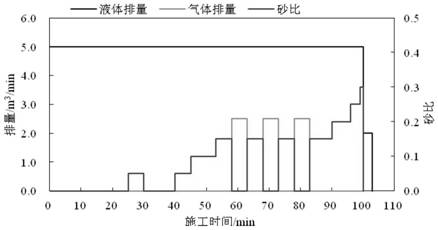

[0067] 2% concentration of active water fracturing fluid is used, and the gas is N 2 , fracturing fluid displacement 5m 3 / min, the ceramsite proppant of 100 mesh (0.149mm) and 30 / 60 mesh (average particle size 0.324mm) was selected as the proppant, the liquid was pumped continuously, the on-off period of the electromagnetic control valve 4 was set to 5min, and the pulse Discontinuous pumping of gas and proppant, using pulse capability to promote fracture expansion and horizontal movement of proppant, fracturing procedures such as Figure 4 shown.

[0068] Steps 1-6 are the same as steps 1-6 in Example 1.

[0069] (7) at 0.5m 3 Add 30 / 60 mesh ceramsite proppant and active water to the sand mixing tank at a speed of 1 / min to prepare a sand mixing liquid with a sand ratio of 10%, and pump it into the formation for 6 minutes; increase the sand ratio to 15%, and the pumping time is 5 minutes; Increase the sand ratio to 20% again, and stop adding sand after 4 minutes.

[0070]...

Embodiment 3

[0077] The fracturing procedure is the same as in Example 2, but the fracturing fluid is slow-release acid fracturing fluid, and the gas is CO 2 , fracturing fluid displacement 4m 3 / min, ceramsite proppants of 100 mesh (0.149mm) and 20 / 40 mesh (average particle size 0.55mm) are used as proppants. Using acidic liquids and acidic gases with Ca in reservoir 2+ , Mg 2+ Mineraloids undergo chemical reactions, dissolve rocks, increase fluid flow channels in reservoirs, and improve fracture conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com