Up-down floating type concrete acoustic vibrator

A concrete and floating technology, applied in construction, building structure, construction material processing, etc., can solve problems such as limited operation scope and cumbersome vibrating operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

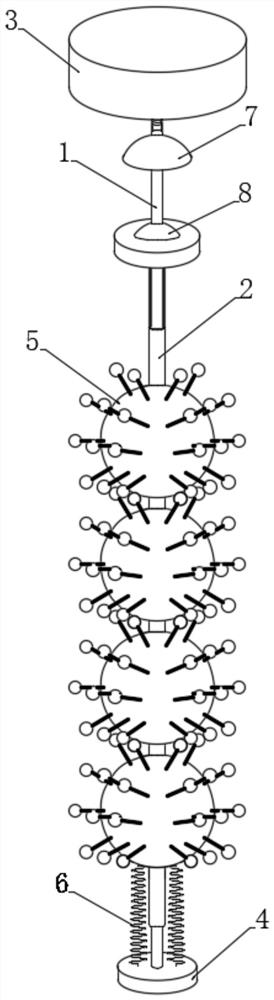

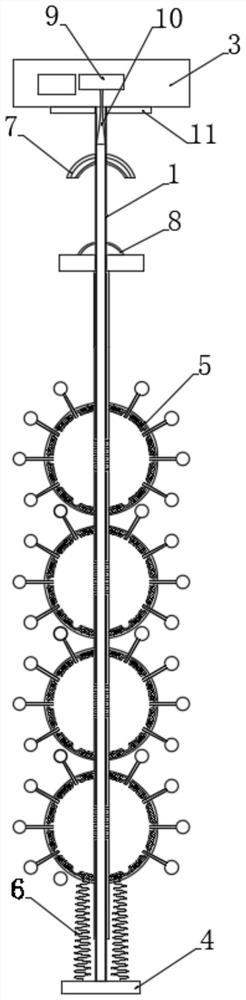

[0036] see Figure 1-3 , an up and down floating concrete acoustic vibrator, comprising a vibrating rod 1 and an upper console 3 fixedly connected to the upper and lower ends of the vibrating rod 1 and a lower embedding platform 4, the sliding sealing sleeve on the vibrating rod 1 is provided with a moving sleeve The tube 2 and the outer wall of the moving sleeve 2 are fixedly connected with a plurality of vibrating bodies 5 sequentially from top to bottom. The end face is fixedly connected, the bottom of the upper console 3 inside the upper console 3 is equipped with a magnetic block 11, and the top of the moving sleeve 2 is fixedly connected with a magnetic attractor 8 slidingly sleeved on the vibrating rod 1, vibrating The side wall near the top of the rod 1 is fixedly covered with a magnetic shield 7 corresponding to the position of the magnetic absorber 8, and the magnetic attraction of the magnetic absorber 11 to the magnetic attractor 8 is used to realize the moving sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com