Small part 3D printer

A technology for 3D printers and parts, applied in the field of 3D printers for small parts, which can solve problems such as ear damage, easy noise generation, and impact on hearing health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

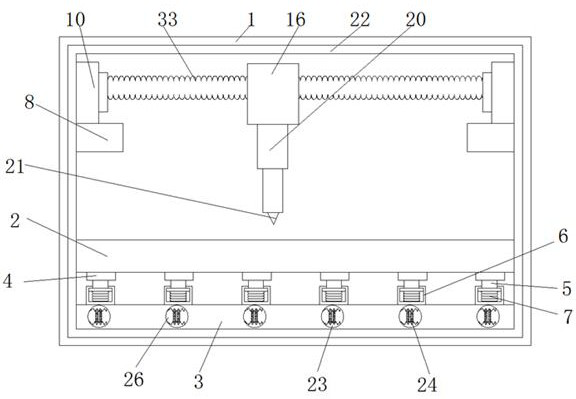

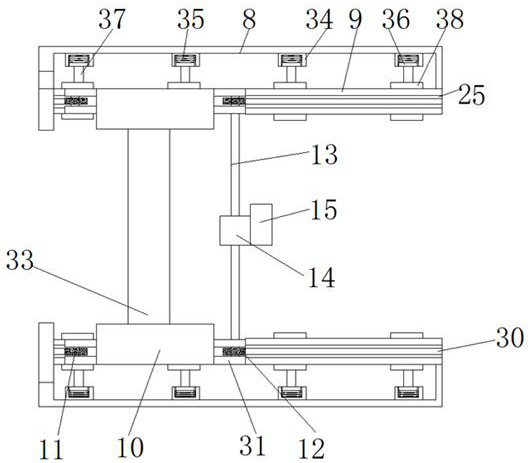

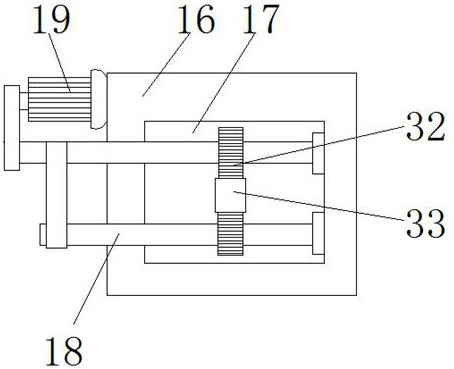

[0022] Embodiments of the present invention provide a small part 3D printer, such as Figure 1-3 As shown, including the chassis 1, the inner wall of the chassis 1 is fixed with a sound-absorbing panel 22, the surface of the sound-absorbing panel 22 is provided with a sound-absorbing hole, the inner side of the sound-absorbing panel 22 is provided with a sound-absorbing sponge, and the interior of the sound-absorbing sponge is provided with a sound-absorbing spring. Board 22 absorbs the noise of the printer in the sound-absorbing sponge through the sound-absorbing hole, adjusts the density of the sound-absorbing sponge through the sound-absorbing spring, buffers the noise, and reduces the damage to the human body caused by the noise. The printing platform 2 is installed inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com