A workbench for soldering and positioning of printed circuit boards

A printed circuit board, welding positioning technology, used in printed circuits, welding equipment, manufacturing tools, etc., can solve problems such as reducing welding accuracy, and achieve the effect of improving quality and efficiency, convenience and stability, and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

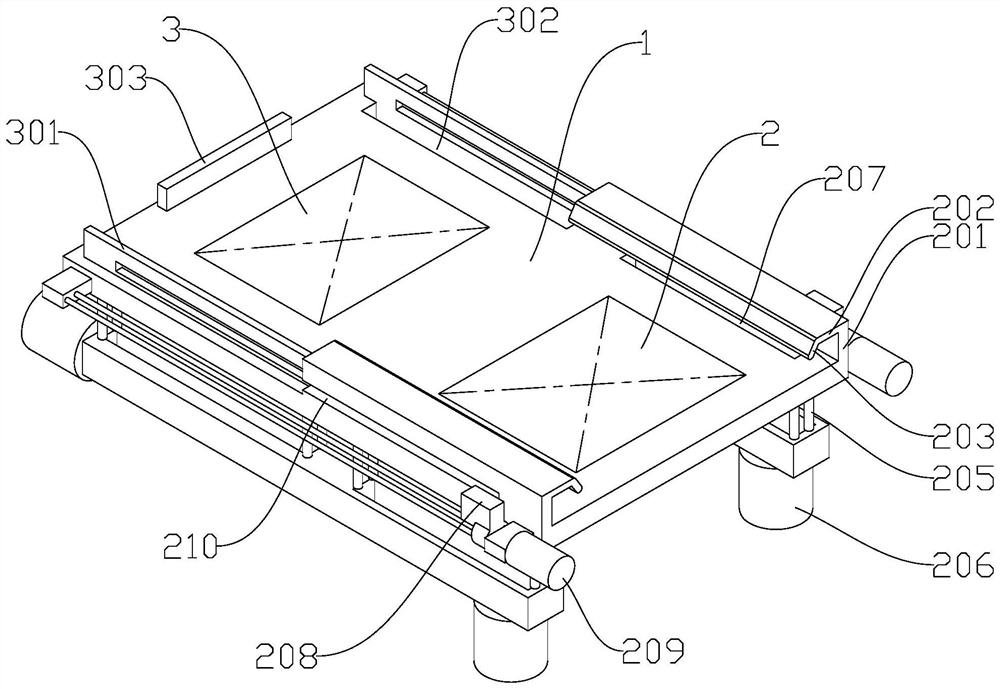

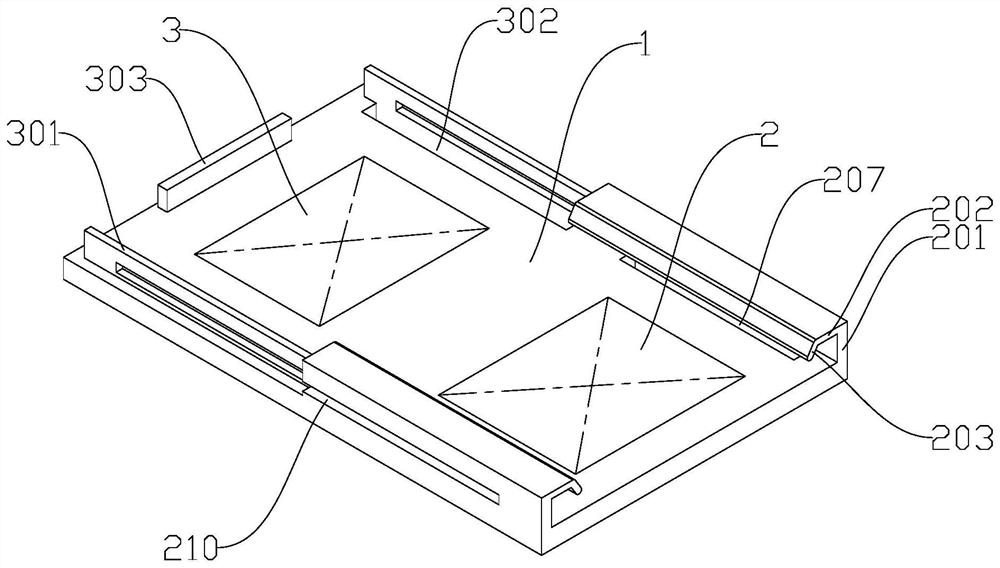

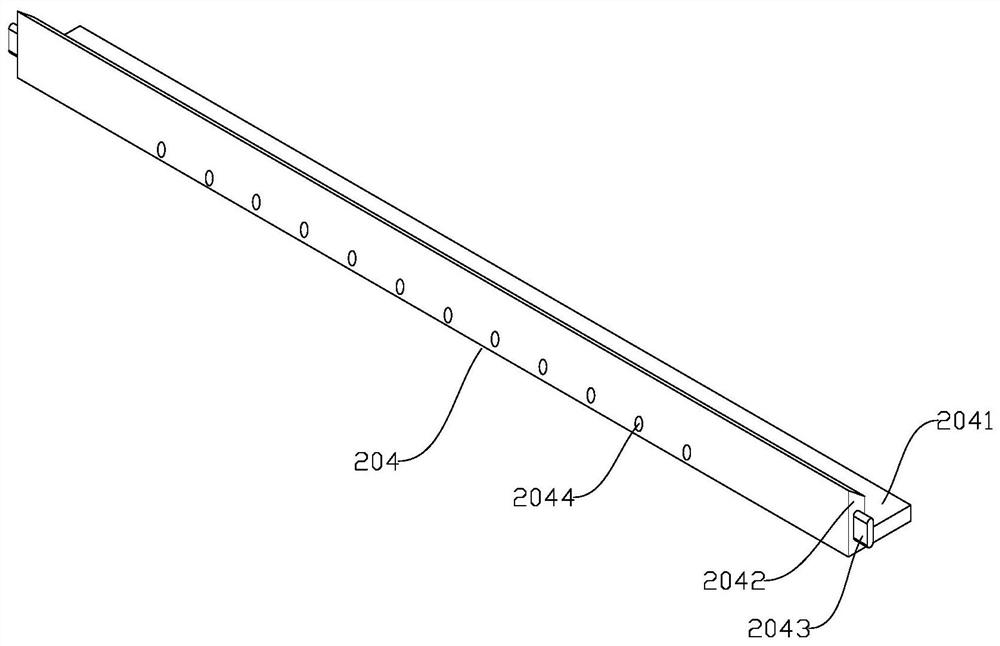

[0040] Such as Figure 1-7 As shown, the present invention proposes a workbench for soldering and positioning of printed circuit boards, which is mainly used for the precise positioning of printed circuit board materials 4 on the automatic production line during the automatic soldering process, including the work base 1, when used , place the working base 1 on the horizontal platform. Specifically, the middle position of the bottom surface of the working base 1 can be placed on the horizontal platform frame along the length direction, so that the upper plane of the working base 1 is in a horizontal position. The working platform 1 is provided with a positioning area 2, and the two opposite sides of the positioning area 2 are respectively pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com