Test tube cleaning mechanism of water quality detection device and water quality detection device

A water quality detection and cleaning mechanism technology, applied in lighting and heating equipment, dryers, cleaning hollow objects, etc., can solve the problems of poor accuracy of detection results, high cost, manual operation errors and uncertainties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

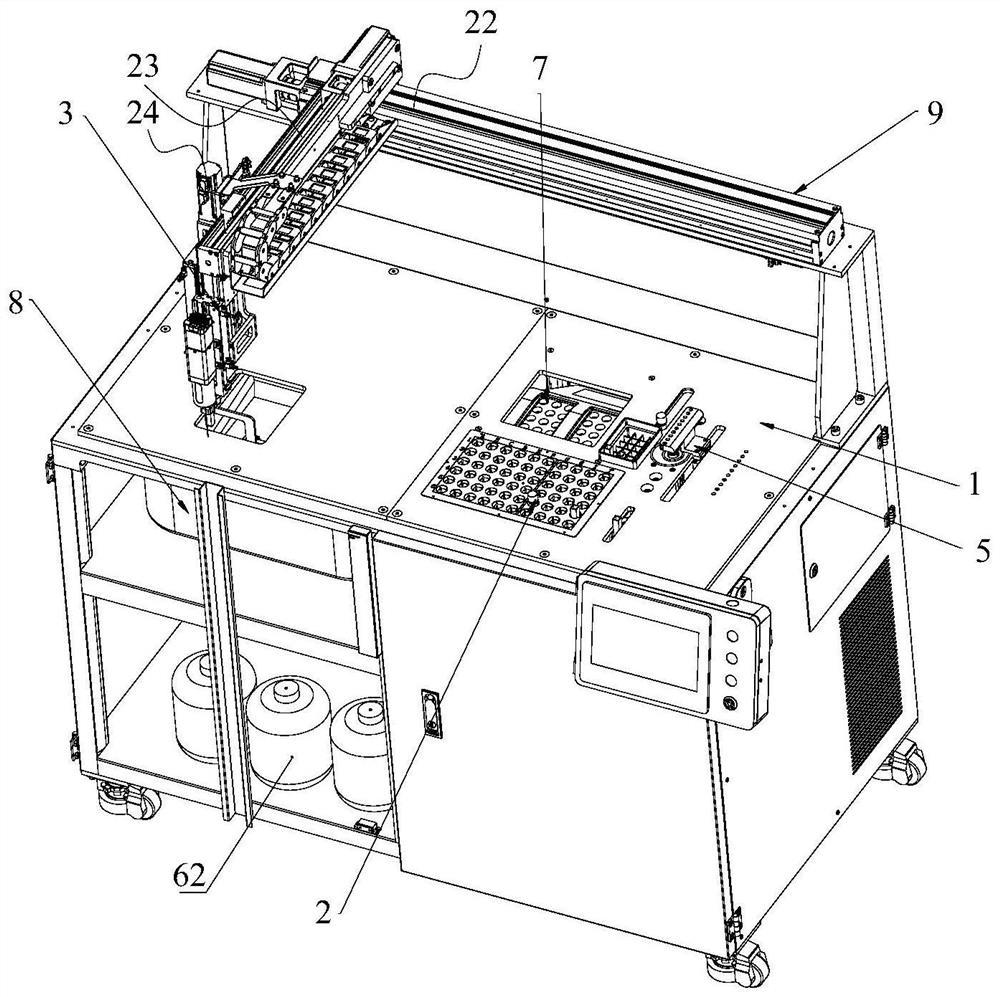

[0068] Such as Figure 1-13 Shown, a kind of water quality detection equipment, can automatically detect water quality, comprises frame 1, is installed on frame 1;

[0069] Storage rack 2, for placing test tube and cuvette 66;

[0070] Mobile grabbing mechanism 3 for grabbing items and taking samples;

[0071] The switch cover mechanism 4 is used to open or close the test tube cover 71 of the test tube;

[0072] The dosing mechanism 5 is used to add medicine to the test tube body 46;

[0073] Shaking mechanism 6, used to fully mix the sample and the medicament;

[0074] Digester 7, used to heat and digest the shaken liquid;

[0075] The detector 8 is used to detect the liquid in the contrast color dish 66 .

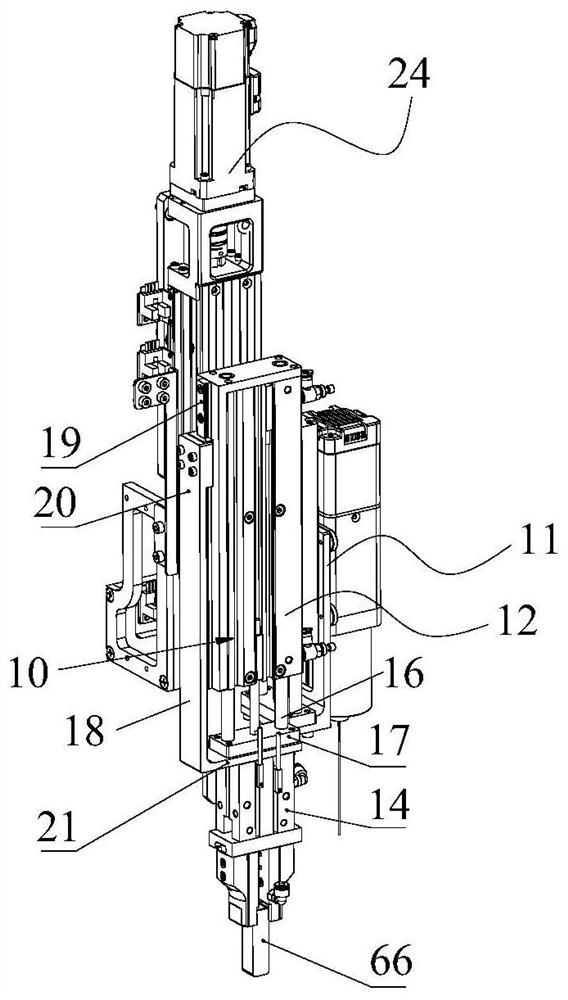

[0076] Such as figure 2 , 3 Shown in and 4, in the present embodiment, mobile grasping mechanism 3 comprises:

[0077] a mobile unit 9;

[0078] The mounting frame 11 is installed on the mobile unit 9;

[0079] The first lifting element 12 is installed on the m...

Embodiment 2

[0160] Such as Figure 17 and 18As shown, the difference between this embodiment and Embodiment 1 is that the digestion apparatus 7 is removed in this embodiment, and a heating element 70 is added on the basis of the shaking mechanism 6 in Embodiment 1 to form a shaking heating mechanism. Such as Figure 17 and 18 As shown, the shake well heating mechanism consists of:

[0161] the first rotating element 43;

[0162] The second rotating element 44 is fixed to the rotating shaft of the first rotating element 43, and the rotating shaft axis of the second rotating element 44 is perpendicular to the rotating shaft axis of the first rotating element 43;

[0163] The test tube self-clamping sleeve 45 is fixed to the rotating shaft of the second rotating element 44 for automatically clamping the test tube body 46 , and the test tube self-clamping sleeve 45 is equipped with a heating element 70 .

[0164] Through the first rotating element 43 and the second rotating element 44 , ...

Embodiment 3

[0171] The difference between this embodiment and embodiment 1 or 2 is that test tube and switch cover mechanism 4 are different, as Figure 19 and 20 As shown, the test tube assembly of this embodiment includes a test tube body 46 and a test tube cover 71. The test tube cover 71 is socketed and fitted with the test tube body 46. The test tube cover 71 includes an inner insertion part 72 and an outer outer part 73 arranged coaxially. An annular groove 74 is formed between the outer portion 72 and the outer sleeve portion 73, and the annular groove 74 is used to be clamped on the opening end of the test tube body 46; the inner insertion portion 72 is a cylindrical structure, and the end of the inner insertion portion 72 has a first tapered shape. Guide surface 75; test tube cover 71 is a flexible material, and the inner sidewall 72 of test tube cover 71 is sealed with the inner wall of test tube body 46, and the outer wall of test tube cover 71 is sealed with the outer wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com