Mixing device for producing body wash

A mixing device and shower gel technology, applied in mixers, transportation and packaging, shaking/oscillating/vibrating mixers, etc., can solve problems such as uneven mixing, uneven mixing of various raw materials, and single mixing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

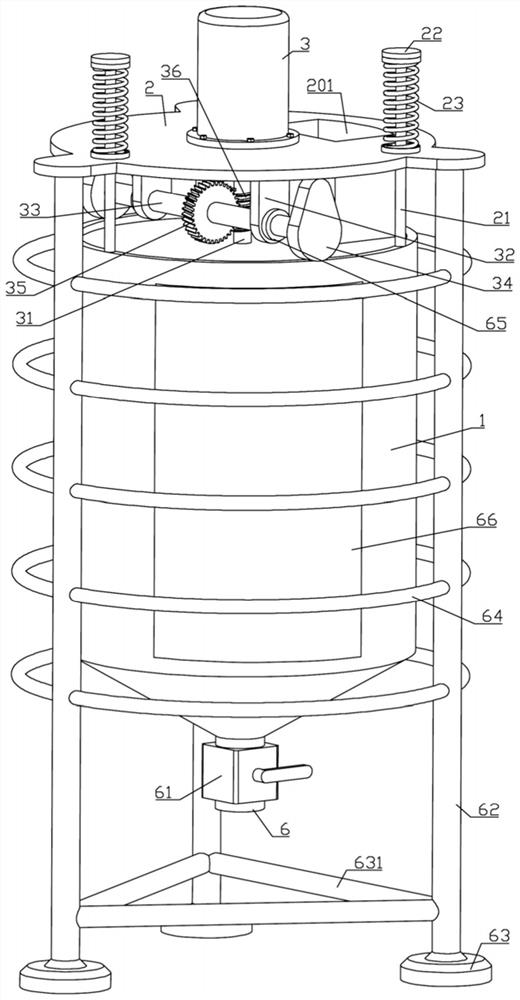

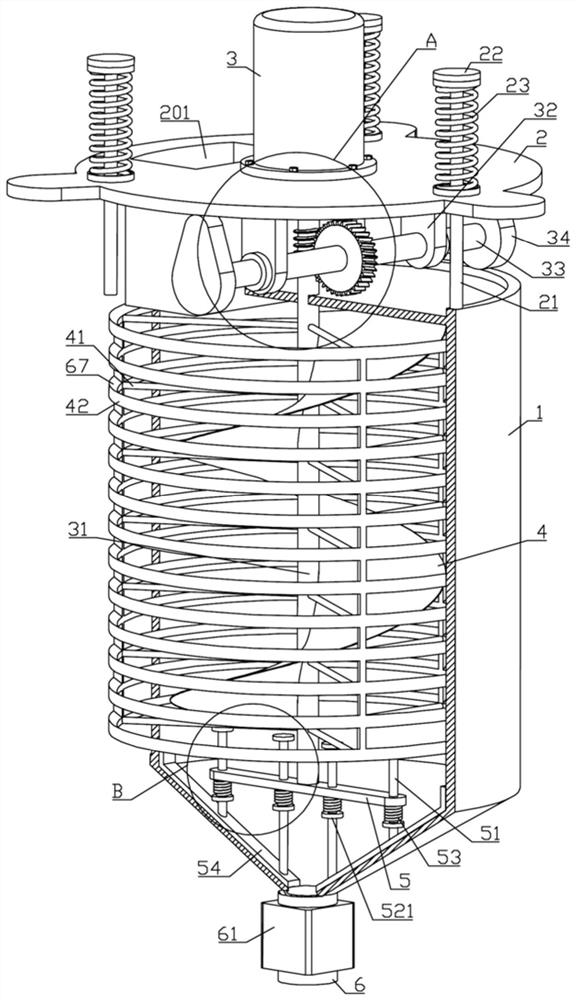

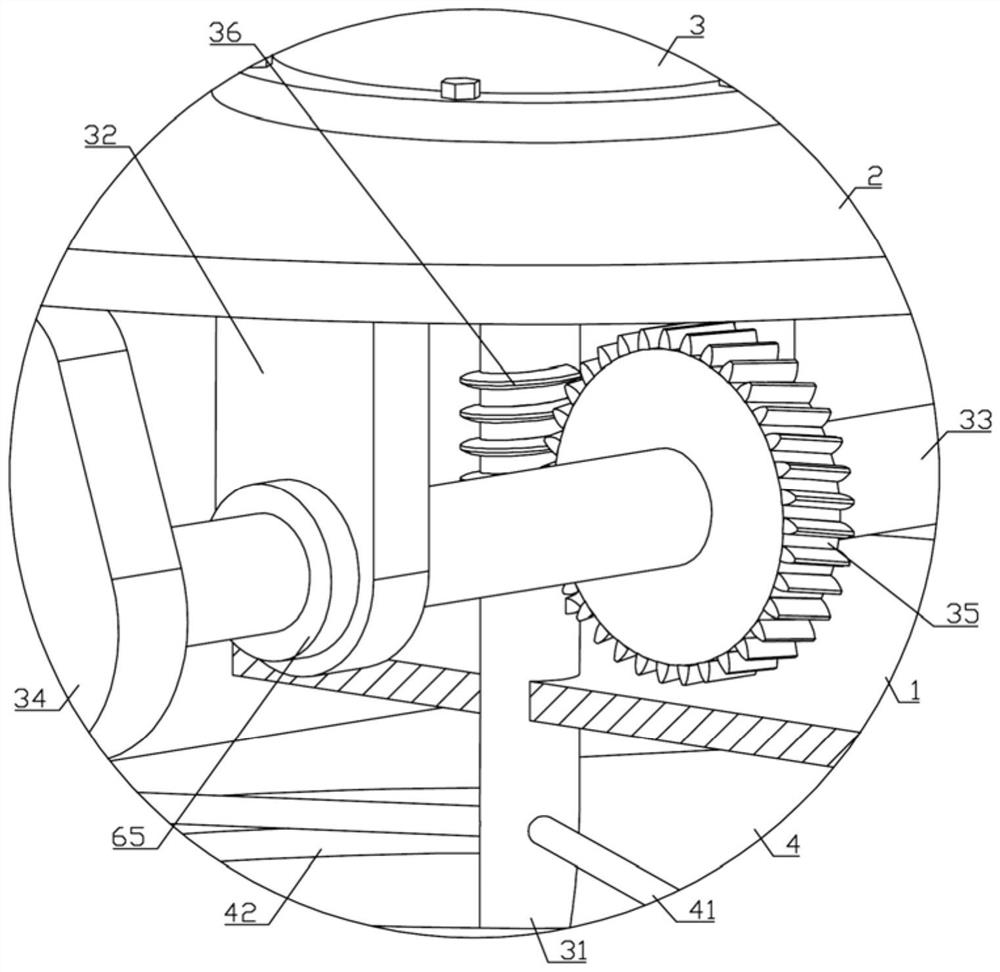

[0028] Such as Figure 1-4 As shown, a mixing device for bath milk production according to the present invention includes a mixing tank 1, a discharge mechanism is provided at the lower end of the mixing tank 1, a support plate 2 is provided on the upper side of the mixing tank 1, and a support plate 2 is provided at the lower end of the support plate 2. Support mechanism, the support plate 2 is provided with a feed hopper 201 matching with the mixing bucket 1, the support plate 2 is slidably connected with a number of first sliding rods 21 fixedly connected with the mixing bucket 1, and the upper end of the first sliding rod 21 is provided with a first A baffle 22, the outer side of the first slide bar 21 is provided with a first spring 23,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com