Solar efficient power generation device

A power generation device and solar technology, applied in the field of solar power generation, can solve the problems of short power generation time, monotonous functions, and large silicon battery consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

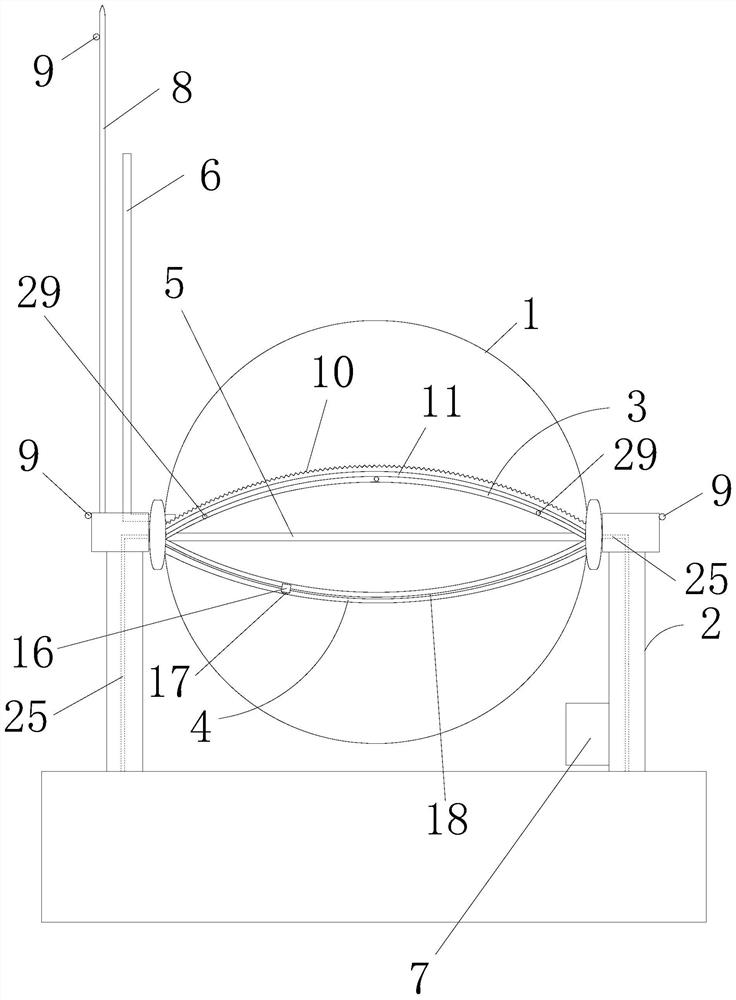

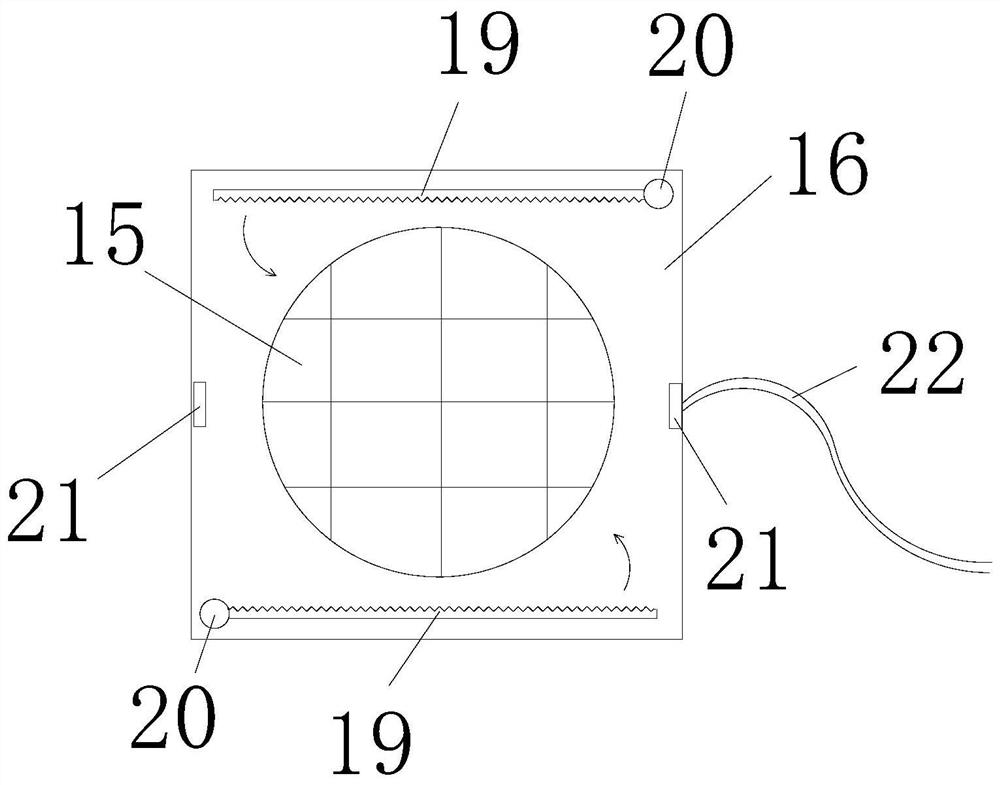

[0043] like figure 1 , 2As shown in the figure, a high-efficiency solar power generation device includes a glass spherical shell 1, which is sealed with a transparent liquid (not shown in the figure) filled inside the glass spherical shell 1. At both ends of the glass spherical shell 1 along the horizontal diameter, there are The fixing bracket 2, around the outer surface of the glass spherical shell 1, is provided with a first semicircular track 3, the two ends of the first semicircular track 3 are respectively connected with the fixing bracket 2 in rotation, and along the outer side of the first semicircular track 3, there is a second semicircular track 3. The two ends of the semicircular track 4 and the second semicircular track 4 are respectively rotatably connected with the fixing bracket 2 . From one fulcrum end of the fixed bracket 2, there is a transparent L-shaped sealed communication connector 6 that communicates with the interior of the glass spherical shell 1. The...

Embodiment 2

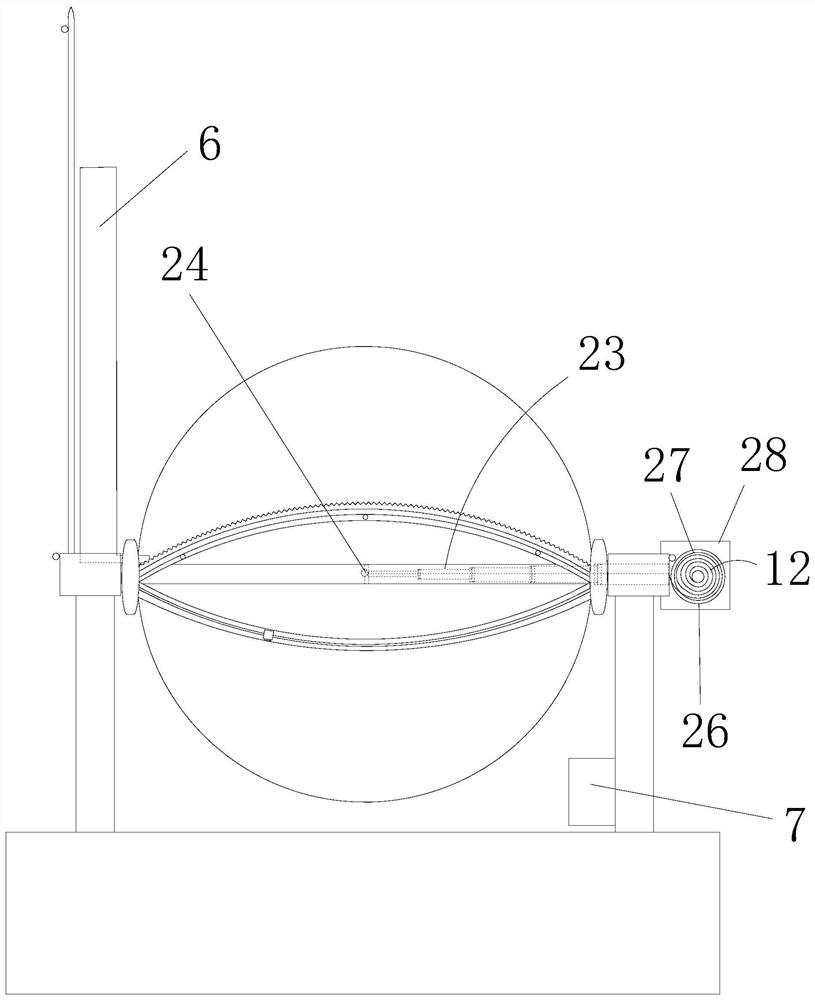

[0053] like image 3 , 4 As shown, the difference from the above-mentioned Embodiment 1 is that this embodiment is provided with an automatic telescopic rod 23 from the other end of the fulcrum of the fixed bracket 2 to the inside of the glass spherical shell 1, and the front end of the automatic telescopic rod 23 is provided. There is an LED light 24, the entrance of the automatic telescopic rod 23 is a sealed structure, the joints between each sleeve 32 of the automatic telescopic rod 23 are respectively provided with sealing rings 33, and the tail end of the automatic telescopic rod 23 is The second rotary motor 26 is connected, the second rotary motor 26 is mounted on the bracket 28 outside the fixed bracket 2 , and the second rotary motor 26 is electrically connected to the controller box 7 . During the day, the automatic telescopic rod 23 is hidden in the end of the fixed bracket 2. The automatic telescopic rod 23 is sleeved by a plurality of sleeves 32 (its structure i...

Embodiment 3

[0055] like Figure 5 As shown, the difference from the above-mentioned Embodiment 1 is that the shape of the fixing bracket 2 in this embodiment is a horseshoe shape. The rest of the content is exactly the same as that in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com