Guardrail water spraying mechanism with good cleaning and wetting effect and using method thereof

A cleaning mechanism and wetting technology, applied in cleaning methods, road surface cleaning, construction, etc., can solve the problems of affecting the aesthetics of the guardrail, the poor washing effect of the guardrail when driving in, and the easy damage of the guardrail, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

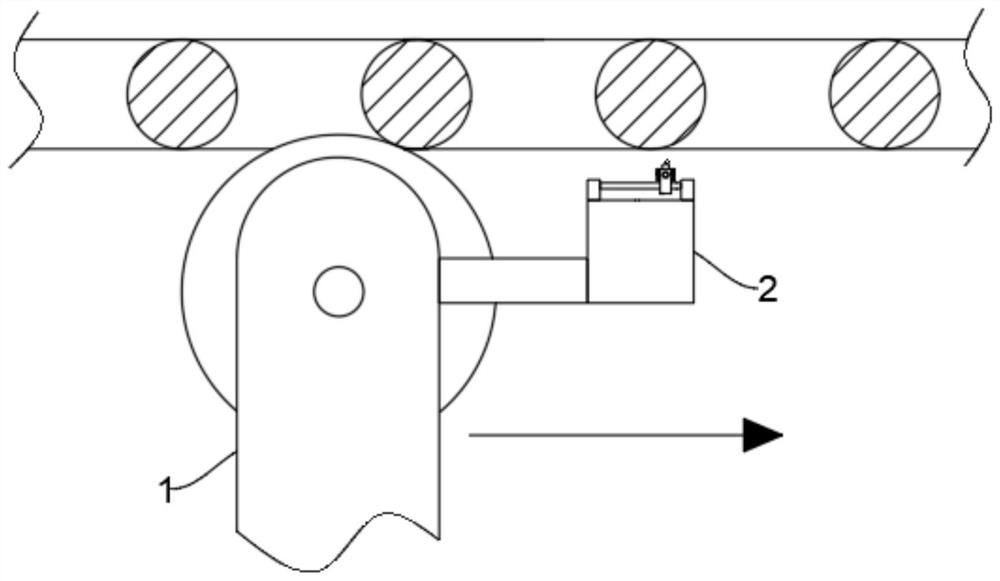

[0037] Such as Figure 1-5 As shown, a guardrail water spray mechanism with good cleaning and moistening effect and its use method include a housing 2 connected with a cleaning mechanism 1. The cleaning mechanism 1 includes structures such as cleaning rollers and a cleaning vehicle body, and is used to clean the front of the vehicle The direction is the front, and the housing 2 is arranged in front of the cleaning roller.

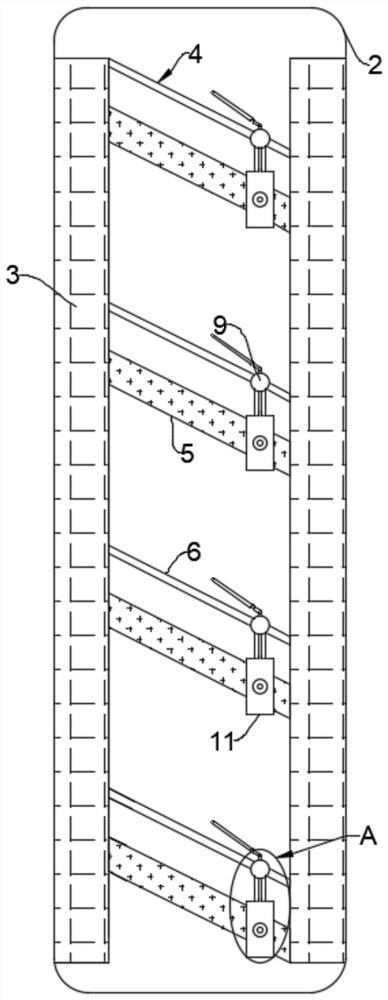

[0038] Such as figure 2 As shown, one side of the housing 2 is fixedly connected with two vertically arranged fixing bars 3, and a plurality of equidistantly distributed sliding rod groups 4 are fixedly connected between the two fixing bars 3, and the sliding rod groups 4 are composed of two mutually The first sliding bar 5 and the second sliding bar 6 are arranged in parallel, and the first sliding bar 5 is located below the second sliding bar 6 .

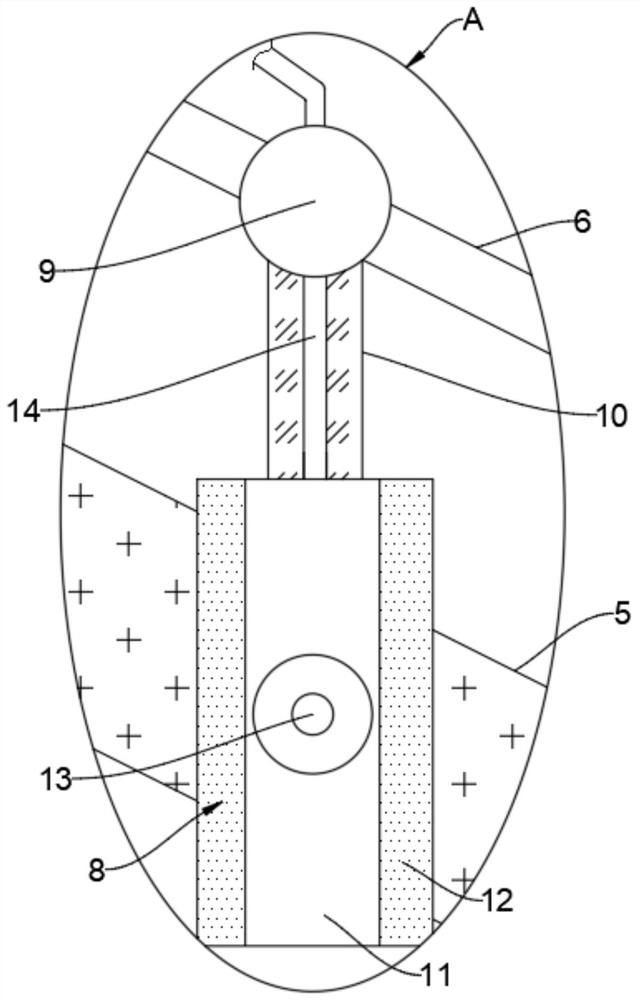

[0039] Such as Figure 4 , Figure 5 As shown, the first sliding bar 5 is slidably connected with a sli...

Embodiment 2

[0051] Such as Figure 6-7 As shown, the difference between this embodiment and Embodiment 1 is that: the first slide bar 5 and the second slide bar 6 are both inclined downward toward the cleaning mechanism 1, and the first slide bar 5 is axially sleeved with Spring 16, the two ends of spring 16 are fixedly connected with fixed bar 3 and sliding block 7 respectively, and spring 16 is positioned at the bottom setting of sliding block 7, and sliding block 7 and positioning ball 9 are respectively positioned at the first slide bar 5 and the second without external force. Slide bar 6 is set at the top.

[0052] When the nozzle 13 moves forward, the nozzle 13 will spray water to clean the guardrail. When the nozzle 13 faces the guardrail and continues to move forward, because the guardrail is made of iron, the guardrail and the magnetic strip 12 will attract each other. The guardrail will generate a backward magnetic attraction force for the magnetic strip 12, and the backward ma...

Embodiment 3

[0056] Such as Figure 8-9 As shown, the difference between the present embodiment and the second embodiment lies in that the connection block 11 is connected with the sliding block 7 for horizontal rotation.

[0057] When the sliding block 7 moves towards the railing, the magnetic strip 12 will be attracted by the railing so that the magnetic strip 12 drives the connecting block 11 and the sliding block 7 to rotate and move horizontally, so that the nozzle 13 is inclined towards the direction of the railing, so that the nozzle 13 ejects Water can be sprayed toward the railing; when the sliding block 7 moves away from the railing, the magnetic strip 12 will drive the connecting block 11 to rotate backward horizontally, so that the spray head 13 is inclined backward toward the railing.

[0058] Then ensure that the nozzle 13 is always facing the railing in the whole process, and then ensure that the water sprayed by the nozzle 13 can always be sprayed on the railing, thereby gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com