Environment-friendly wet-process paper shredding device for paper-making industry

A papermaking and environmental protection technology, which is applied in the field of environmental protection wet paper shredding device for papermaking industry, can solve the problems of increasing waste paper shredding time and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

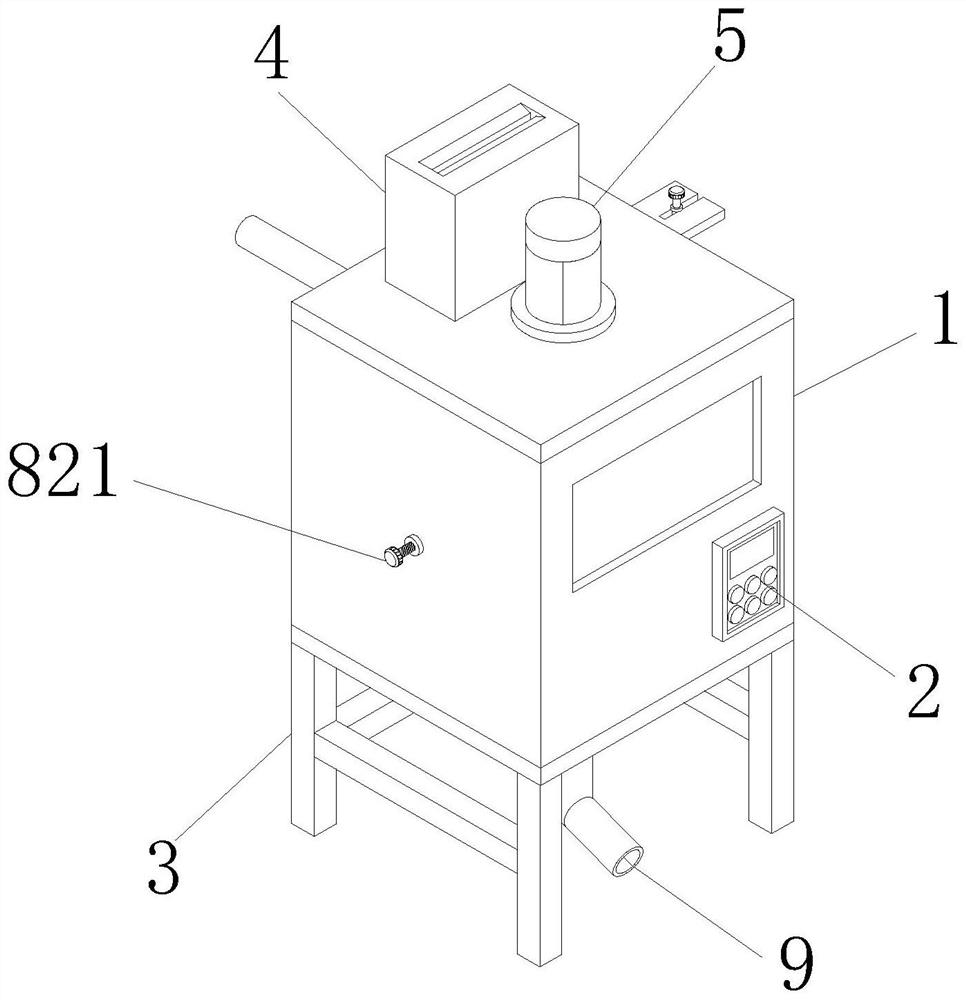

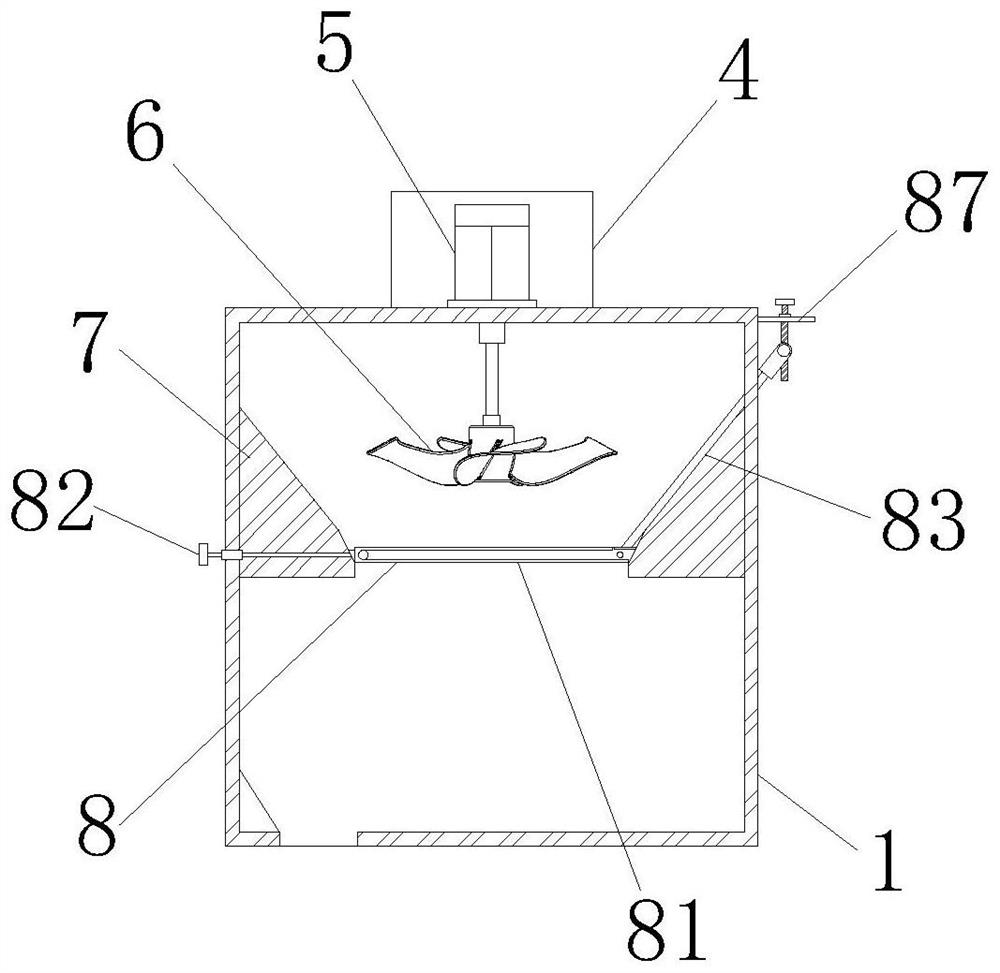

[0028] see figure 1 , the present invention provides an environment-friendly wet paper shredding device for the papermaking industry through improvement, including a casing 1 and a filter device 8, the front end of the casing 1 is locked with the controller 2 by bolts, and the bottom end of the casing 1 is locked by bolts It is mutually locked with the support foot 3, the rear side of the top of the casing 1 is locked with the paper shredder 4 through bolts, the middle part of the top of the casing 1 is locked with the motor 5 through bolts, and the output shaft at the bottom of the motor 5 is connected with the stirring blade through the rotating shaft. 6 phases are connected, the middle part of the left and right sides inside the casing 1 is locked with the support slant plate 7 by bolts, the bottom end of the support swash plate 7 is equipped with a filter device 8, and the left side of the bottom end of the casing 1 is connected with a discharge pipe 9, supporting There ar...

Embodiment 2

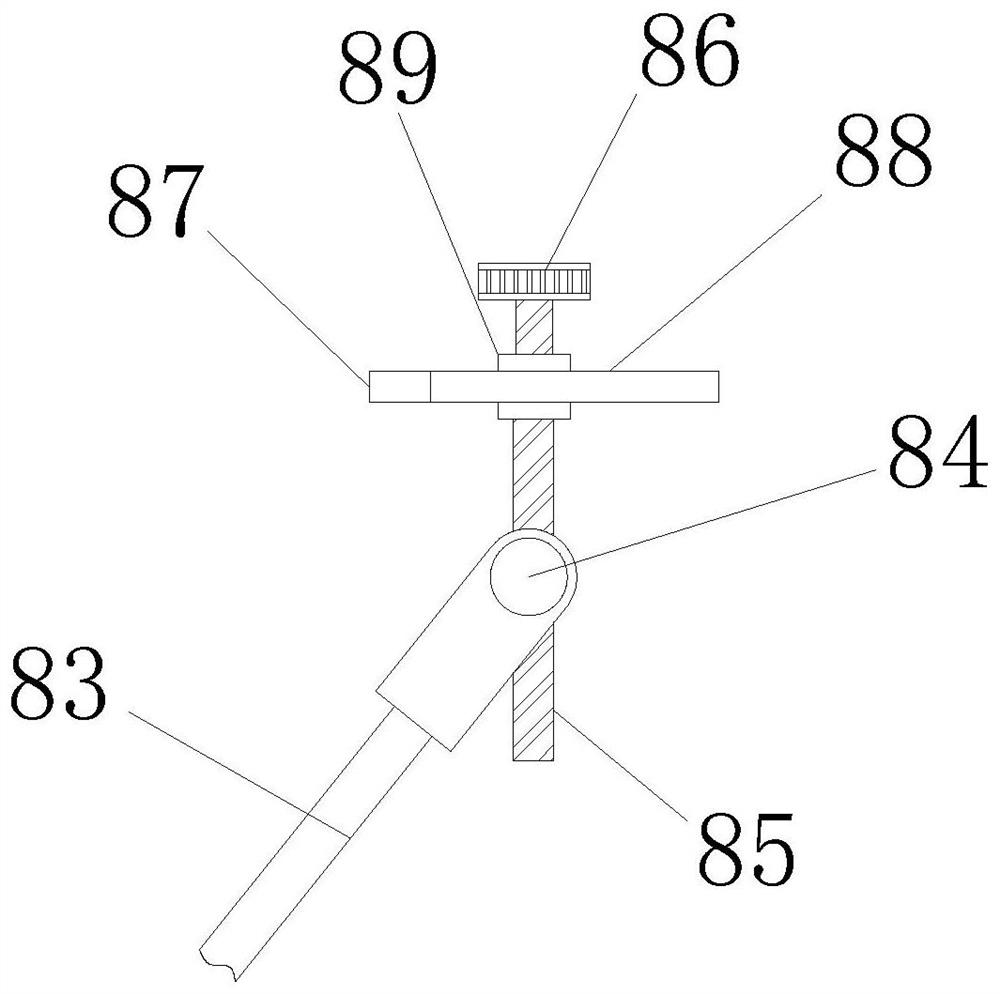

[0033] The present invention provides an environment-friendly wet paper shredding device for the papermaking industry through improvement. There is an opening on the top right side of the second chute 815, and baffle plates are welded on the top of the right side of the front and rear sides of the outer frame 811, so that the sliding rod 813 extends Entering into the second chute 815, the bottom end of the right side of the clamping block 827 is smooth, and the clamping block 827 is inclined downward at a forty-five degree angle from right to left, so that when the outer frame 811 squeezes the clamping block 827 to the left , the block 827 moves upward.

[0034] The present invention provides an environment-friendly wet shredding device for the paper industry through improvement, and its working principle is as follows;

[0035] First, before use, first place the device on the required plane position through the supporting feet 3, then connect the controller 2 with an external...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com