Hyaluronic acid fiber material and preparation method thereof

A technology of hyaluronic acid and fiber materials, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve problems that limit the application of hyaluronic acid fiber materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Mix 0.4g of high-molecular methacrylylated hyaluronic acid (Mw=1.8 million Da), 0.2g of low-molecular-weight methacrylated hyaluronic acid (Mw=500,000Da), and 0.3g of polyethylene oxide Alkanes (Mw=1 million Da) were respectively dissolved in 5 ml of 70% formic acid-water solution. Mix the two solutions to a total of 10ml, add 0.1g of chitosan quaternary ammonium salt and 0.01g of photoinitiator I2595, stir evenly, and centrifugally defoam to obtain an electrospinning solution;

[0049] The electrospinning solution was placed in the liquid storage device of the electrospinning equipment (Japan MECC nano electrospinning machine, model: NANON-01A), and electrospinning was performed to obtain electrospun fibers. Among them, the electrospinning conditions are as follows: the inner diameter of the capillary needle is 0.6mm, the spinning voltage is 15kV, and the receiving distance between the spinneret and the receiving screen is 20cm;

[0050] The obtained electrospun fiber...

Embodiment 2- Embodiment 5

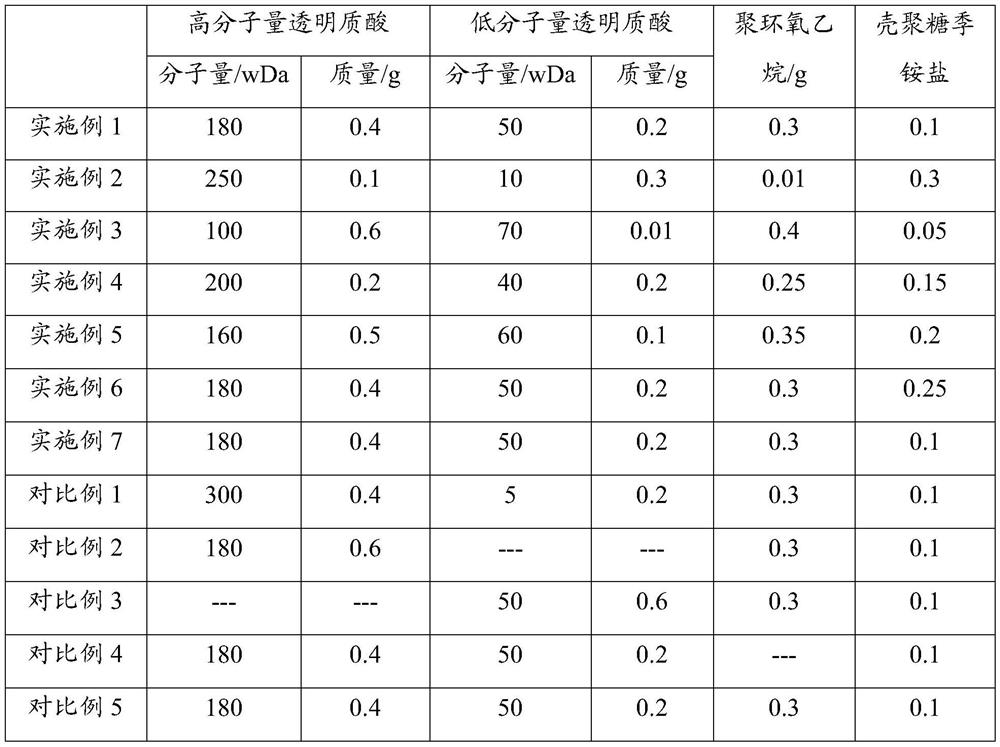

[0052] The difference between Examples 2-5 and Example 1 lies in the content and molecular weight of polyethylene oxide, chitosan quaternary ammonium salt, high-molecular-weight hyaluronic acid and low-molecular-weight hyaluronic acid. See Table 1 for detailed parameters. Other operating steps are the same as in Example 1.

Embodiment 6

[0054] The difference between Example 6 and Example 1 lies in the modification groups and cross-linking methods of the hyaluronic acid used. In Example 6, mercaptolated hyaluronic acid is used, and the cross-linking method adopts the method of curing and cross-linking by introducing oxygen. Concrete preparation steps are as follows:

[0055] Mix 0.4g of high-molecular mercapto-hyaluronic acid (Mw=1.8 million Da), 0.2g of low-molecular-weight mercapto-hyaluronic acid (Mw=500,000 Da), and 0.3g of polyethylene oxide (Mw=1 million Da) were respectively dissolved in 5 ml of 70% formic acid-water solution. Mix the two solutions to a total of 10ml, stir evenly, and centrifuge to defoam to obtain an electrospinning solution;

[0056] The electrospinning solution is placed in the liquid storage device of the electrospinning equipment, and electrospinning is performed to obtain electrospinning fibers. Among them, the electrospinning conditions are as follows: the inner diameter of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com