Heavy-load operation lifting appliance

A spreader and operation technology, applied in the direction of load hanging components, safety devices, track systems, etc., can solve problems such as failure to meet assembly requirements and safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

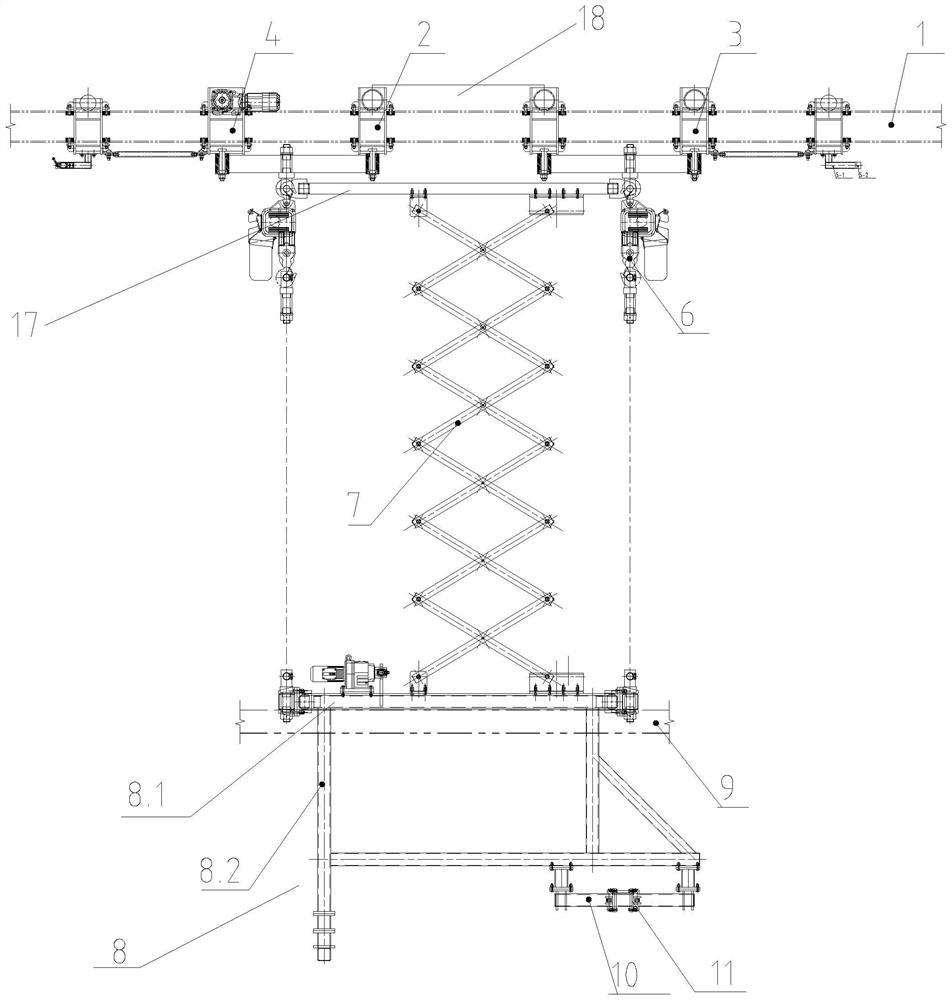

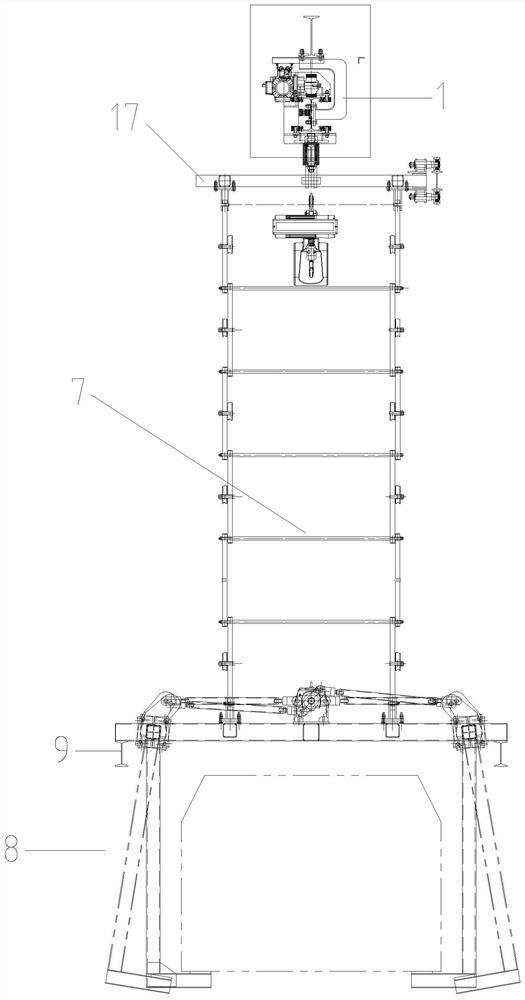

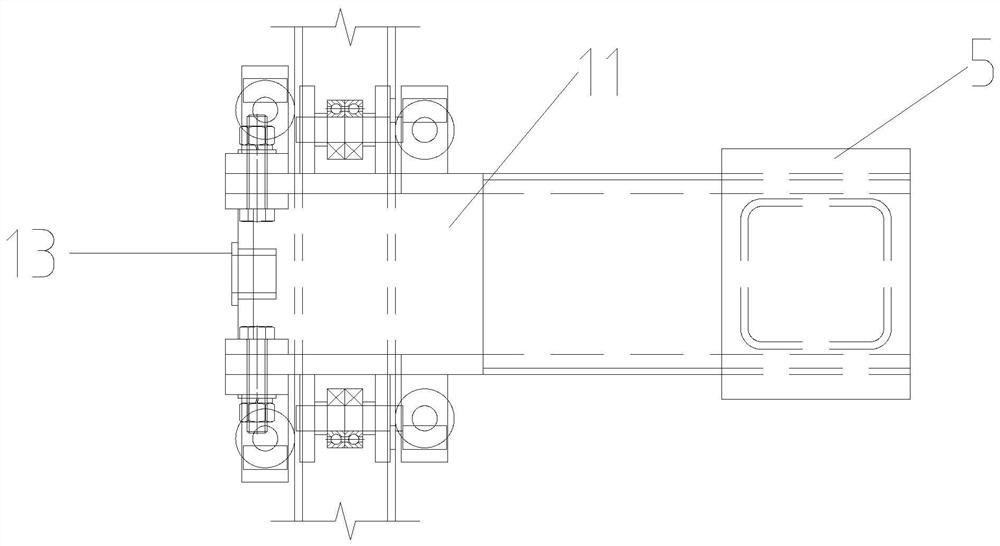

[0024] Such as figure 1 The heavy-duty work spreader shown in —7 comprises a walking track 1, a walking trolley arranged on the walking track 1 and a hoisting bracket 8, a walking bracket 17 is hoisted and fixed on the walking trolley, and the walking bracket 17 is connected with the hoisting bracket 8 Lifting device is arranged, and lifting device comprises electric hoist 6 and scissors fork 7. The walking trolley comprises a driving main vehicle 2 and a follow-up auxiliary vehicle 3 fixed with the driving main vehicle 2 by a connecting beam 18. The front end of the driving main vehicle 2 and the rear end of the following auxiliary vehicle 3 are respectively provided with a front anti-collision structure and a rear anti-collision structure. Hit the structure. The front anti-collision structure includes a front anti-collision beam 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com