Luggage cloth winding device

A technology for fabric rolls and bags, which is used in transportation and packaging, coiling strips, and thin material handling, etc., can solve problems such as lack of fixtures, hidden dangers, and increased safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

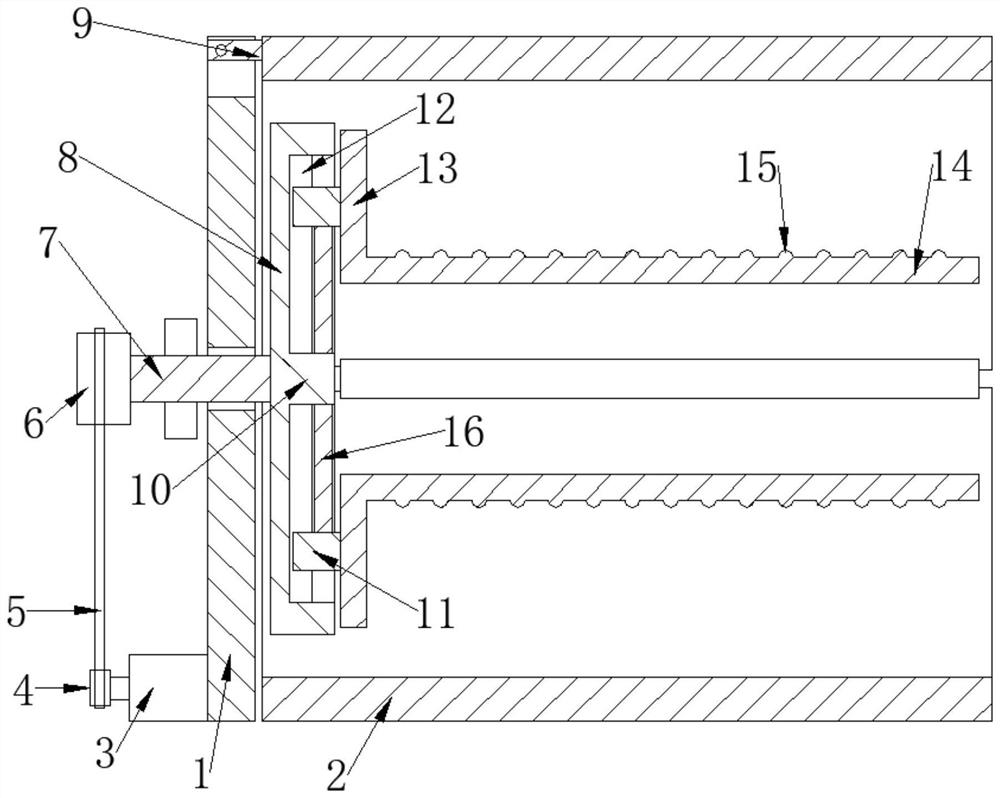

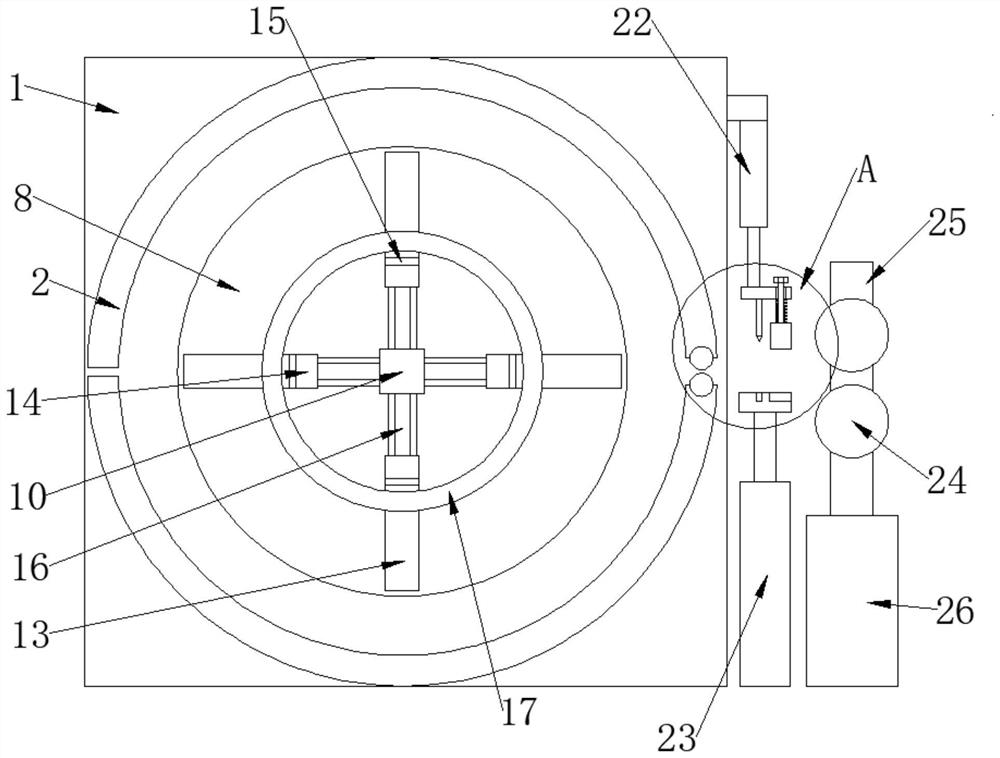

[0025] see Figure 1-6 , the present embodiment provides a bag fabric rolling device, including a fixed frame 1, a guide transfer structure and a rotating disk 8, the guide transfer structure includes a fixed support leg 26, the support leg 26 is fixedly connected with a mounting Rod 25, two guide rollers 24 for guiding and transferring are arranged on the mounting rod 25, the transmission shaft 7 is fixedly connected to the rotating disk 8, and the transmission shaft 7 runs through the fixed frame 1, so The side of the rotating disk 8 is provided with a number of cloth roller brackets, the cloth roller bracket includes a sliding block 11, a vertical strut 13 and a horizontal strut 14, and the side of the rotating disk 8 is provided with a number of "T" shaped sliding grooves 12 , the sliding block 11 is slidably disposed in the sliding groove 12, the vertical strut 13 is fixedly connected to the sliding block 11, and the horizontal strut 14 is fixedly connected to the vertica...

Embodiment 2

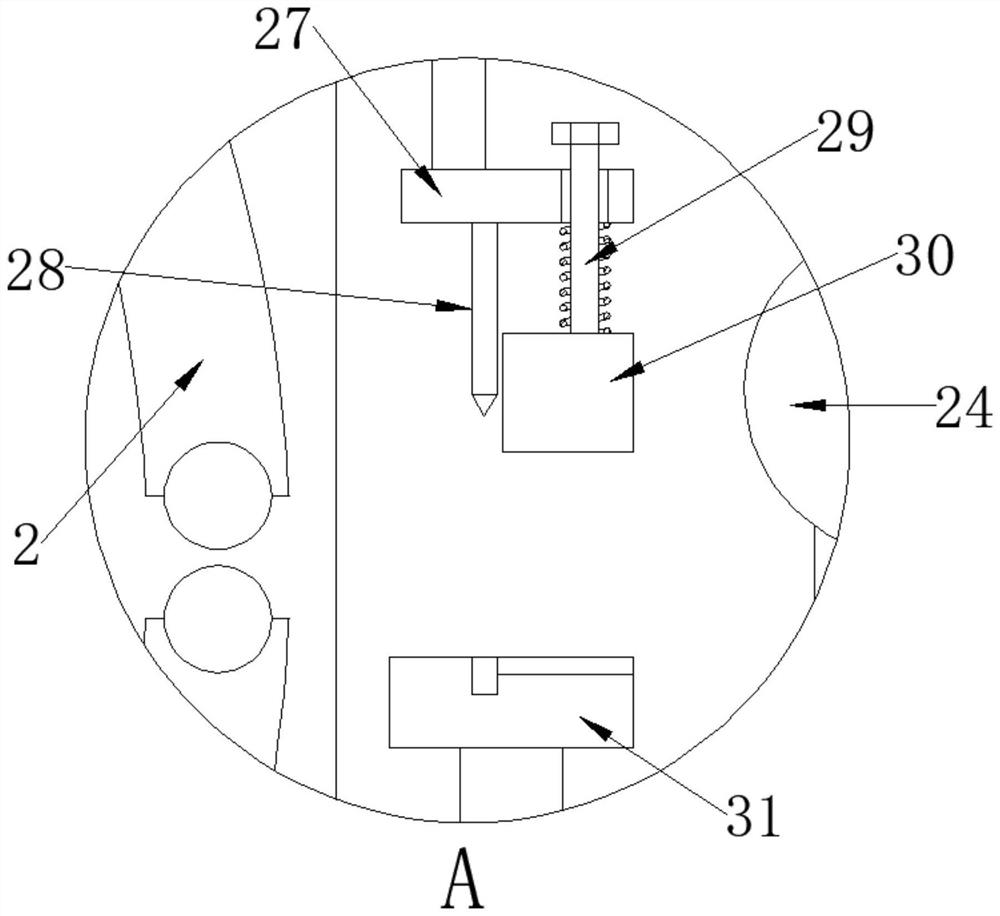

[0036] see figure 2 and image 3 , on the basis of Embodiment 1, a sliding bar 29 is slidably arranged on the cutting frame 27, and the lower end of the sliding bar 29 is fixedly connected with a cover pressing bar 30, and the sliding bar 29 is located between the cutting frame 27 and the cover pressing bar 30. The positions between are provided with compression springs, the position of the lowest point of the cover pressure strip 30 is lower than the position of the lowest point of the cutting knife 28, and the cutting table 31 is provided with the cutting knife 28 and the cover pressure strip 30. Corresponding gap, by being provided with cover bead 30 and described cover bead 30 contacts cloth first, can cut off after cloth is suppressed, makes incision more neat, and described cover bead 30 can not rise automatically, so that Catch the cloth head in the process of changing the cloth roll 17, and then control it to rise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com