Modular universal suction tool

A general-purpose, modular technology that can be used in chemical instruments and methods, lamination auxiliary operations, conveyors, etc., to solve problems such as easy bending of gaskets, easy deformation of suction cups, and difficult bending of gaskets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

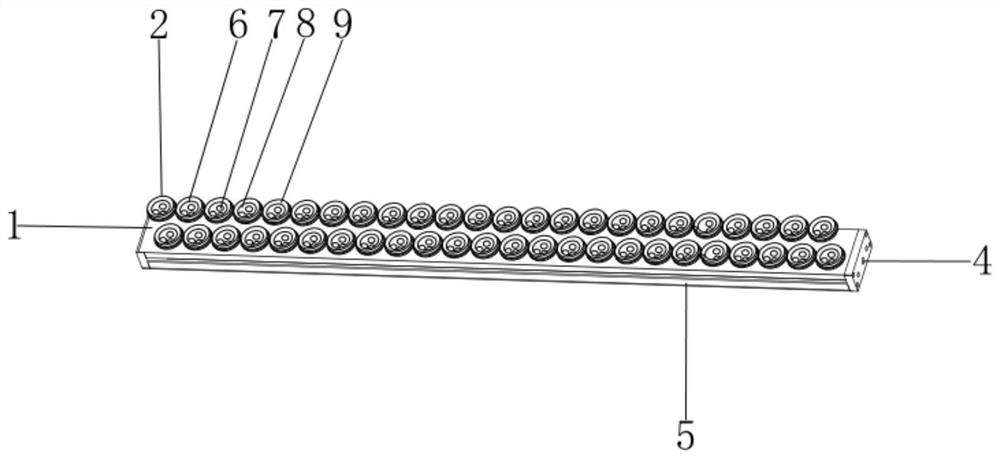

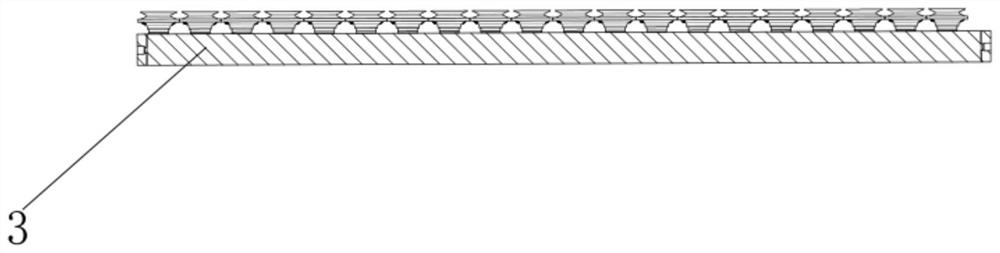

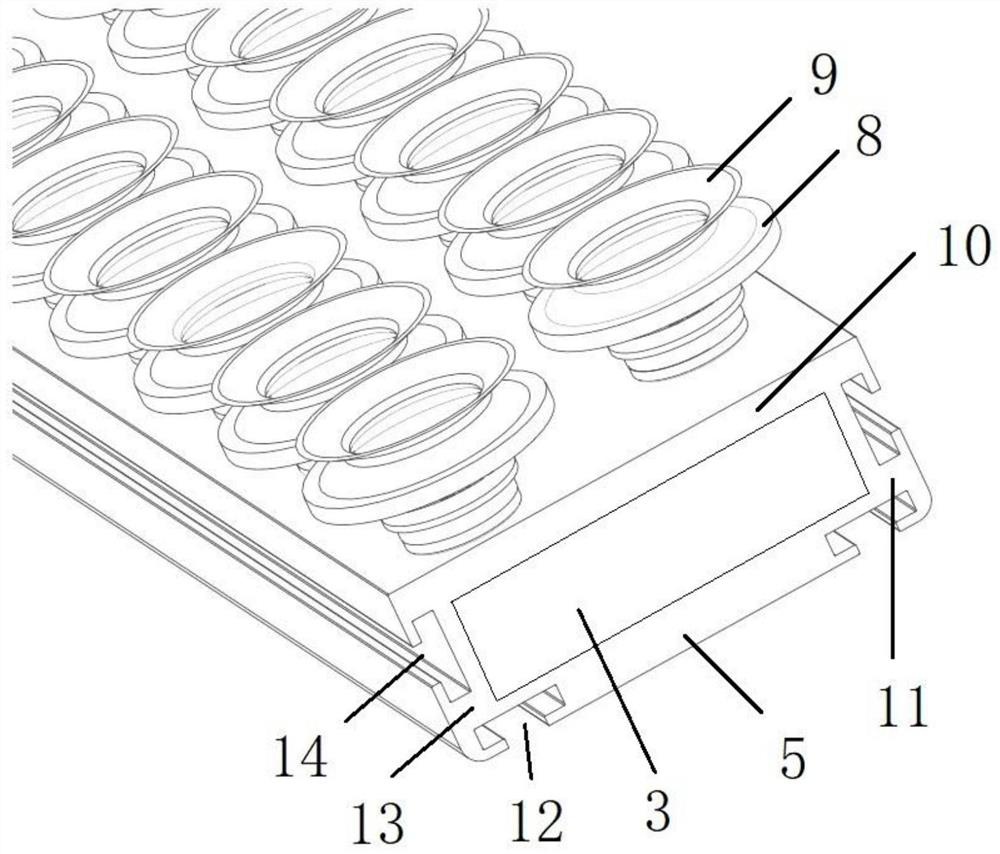

[0019] Such as figure 1 and figure 2 In the shown embodiment, a modular universal suction tool includes a body 1 and a number of suction nozzles 2. The interior of the body 1 is provided with an air chamber 3, and the side end surface of the body 1 is provided with a connection hole 4. The connection hole 4 It communicates with the air chamber 3 , the suction nozzle 2 is connected with the upper end surface of the body 1 , the lower end surface of the body 1 is the bottom plate 5 , and the suction nozzle 2 communicates with the air chamber 3 . The suction nozzle 2 includes a recessed part 6 and a number of adsorption holes 7, the adsorption hole 7 is placed inside the recessed part 6, the recessed part 6 is installed on the upper end surface of the body 1, the adsorption hole 7 communicates with the air chamber 3 inside the body 1, and the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com