Paper printing product water-based printing device good in drying and dust removal effect

A printing device and drying device technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of dust removal effect to be improved, increased horizontal space occupation, easy damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

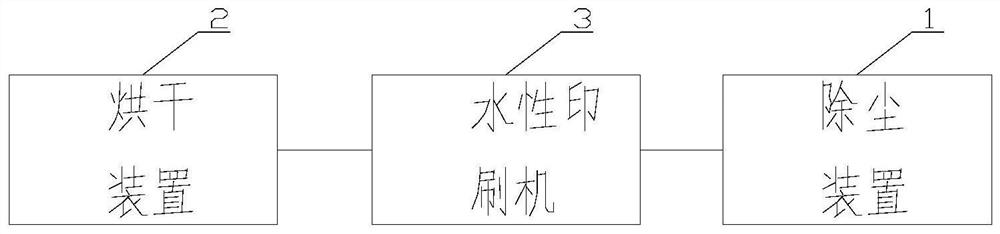

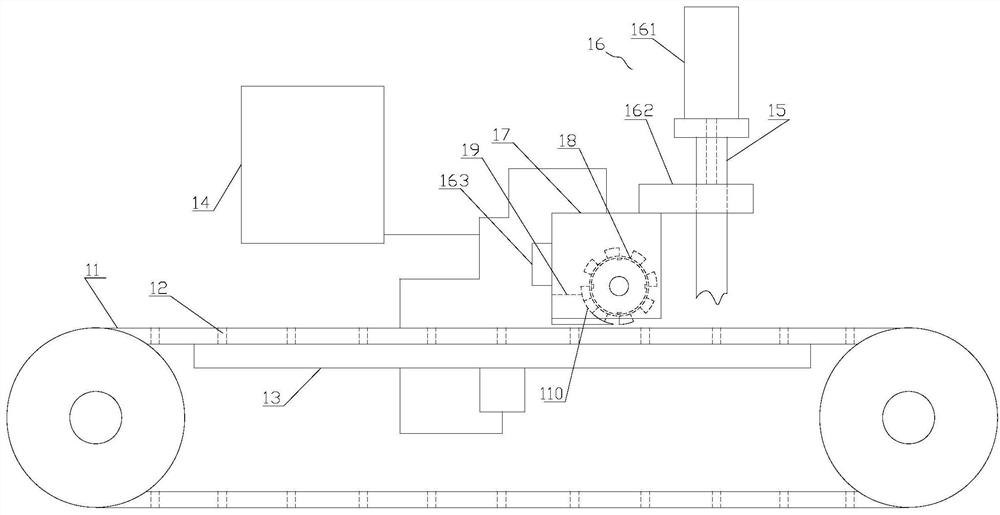

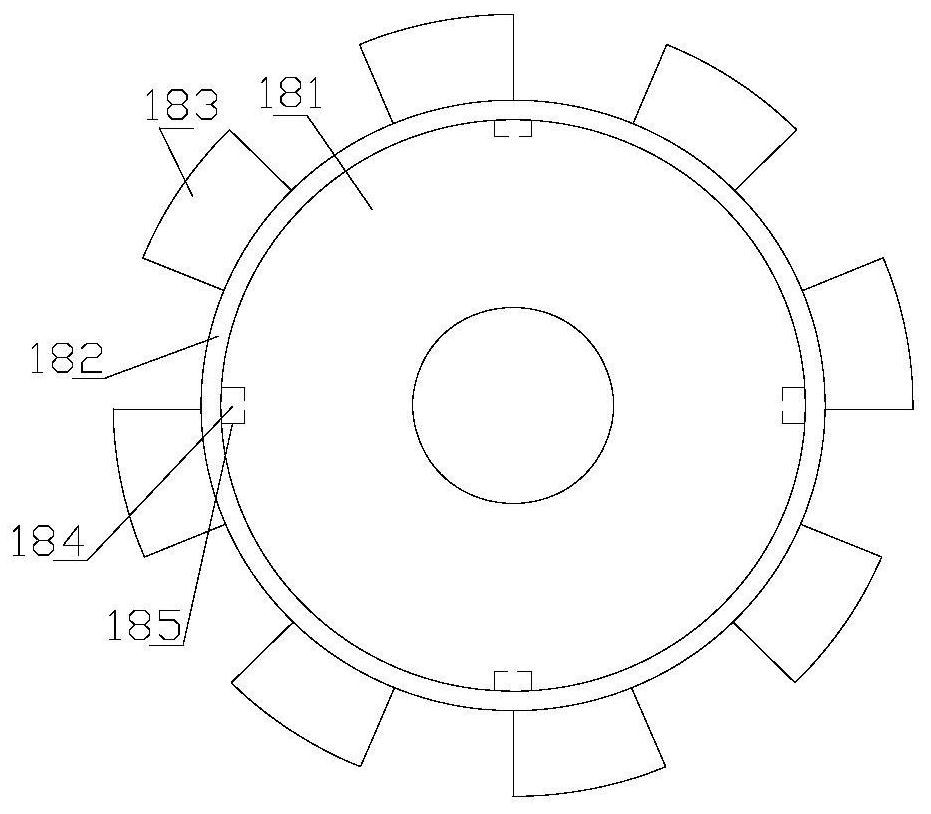

[0023] refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5, the present invention is a water-based printing device for paper printed matter with good drying and dust removal effect, comprising a dust removal device 1, a drying device 2 and a water-based printing machine 3, and the drying device 2, water-based printing machine 3 and dust removal device 1 are composed of Set up in sequence from front to back, the dust removal device 1 includes a plate chain 11, a number of suction holes 12, a gas collecting pan 13, a vacuum cleaner 14, a gantry frame 15, a lifting adjustment mechanism 16, a tank body 17, an electric brush roller 18 and Rubber dust scraping body 19, the beam of the gantry 15 is provided with a lift adjustment mechanism 16, the lower end of the lift adjustment mechanism 16 is provided with a groove body 17, and the inner front side of the groove body 17 is provided with a rubber dust scraper body 19. The tank body 17 is provided with an electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com