Floating powder suction device for pressed powder

A technology for floating powder and powder cake, which is applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning methods using gas flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

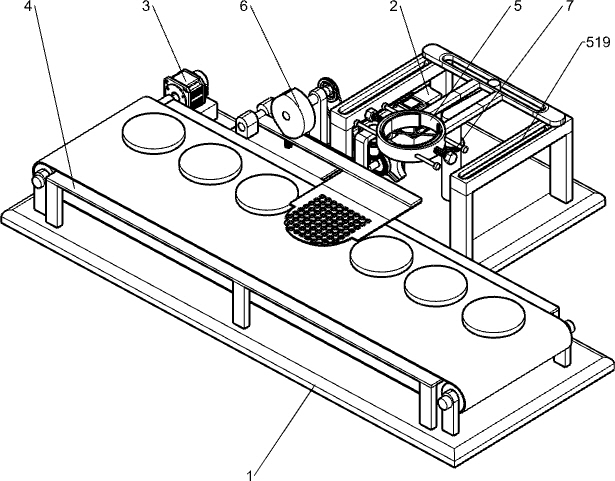

[0038] A powder suction floating powder device, such as figure 1 As shown, it includes a base 1, a drive motor 2, a material transport mechanism 3, a working plate 4 and an intermittent mechanism 5. The drive motor 2 is installed on the left side of the rear side of the base 1, and the material transport mechanism 3 is provided on the front side of the base 1. The base 1 The front side is provided with a working plate 4, and an intermittent mechanism 5 is installed on the rear side of the base 1, and the intermittent mechanism 5 is connected with the driving motor 2.

[0039] When it is necessary to absorb the floating powder on the powder cake, first place the powder cake on the parts of the material conveying mechanism 3, put the dust suction pipe of the vacuum cleaner into the parts of the intermittent mechanism 5 from top to bottom, and then manually start the drive motor 2 and the material conveying mechanism. The parts in the mechanism 3, the feeding mechanism 3 drives t...

Embodiment 2

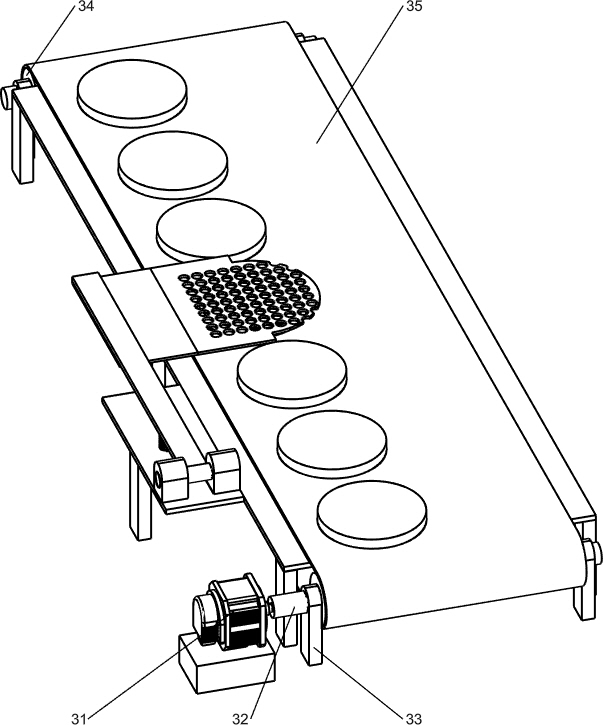

[0041] refer to Figure 1-2 and Figure 4-5 As shown, the feeding mechanism 3 includes a feeding motor 31, a feeding rotating shaft 32, a first support rod 33, a feeding drum 34 and a feeding belt 35, and the left side of the base 1 is equipped with a feeding motor 31, and the feeding motor 31 Intermittent operation, two first support rods 33 are arranged on the left and right sides of the front part of the base 1, and the upper part of the first support rod 33 on the same side is provided with a material delivery shaft 32 in a rotating manner, and the rear side of the left side material delivery shaft 32 The upper part is connected with the output shaft of the feeding motor 31, the feeding drum 34 is arranged on the feeding rotating shaft 32, and the feeding belt 35 is wound between the feeding drums 34 on both sides, and the upper feeding belt 35 is located at the working position. plate 4.

[0042] The powder cake is placed on the material conveying belt 35, then start th...

Embodiment 3

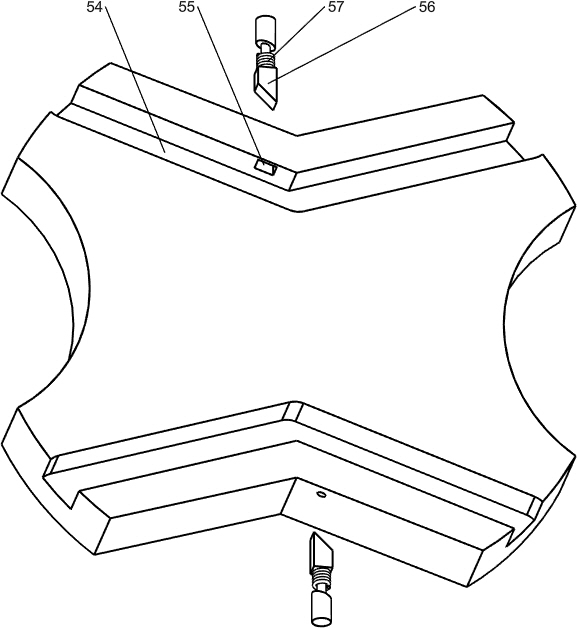

[0046] Specifically, such as Figure 2-3 As shown, a powder pressing mechanism 6 is also included. The powder pressing mechanism 6 includes a support plate 61, a second rotating shaft 62, a second belt assembly 63, a cam 64, a mounting seat 65, a pressing plate 66 and a second spring 67. The left side of the base 1 The rear part is provided with a support plate 61, the upper part of the support plate 61 is rotatably equipped with a second rotating shaft 62, a second belt assembly 63 is connected between the rear side of the second rotating shaft 62 and the front side of the transmission shaft 51, and the front end of the second rotating shaft 62 is provided with Cam 64, mounting seat 65 is arranged on the left side rear part of working plate 4, and mounting seat 65 is provided with pressing plate 66 swingingly, and cam 64 is in contact with pressing plate 66, and second spring 67 is connected between the bottom of pressing plate 66 and working plate 4 tops .

[0047] After st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com