Separation membrane assembly

A separation membrane and component technology, applied in semi-permeable membrane separation, membrane technology, permeation/dialysis water/sewage treatment, etc., can solve the problems of reduced life of membrane elements, reduce membrane service life, ensure recovery rate, and prolong life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

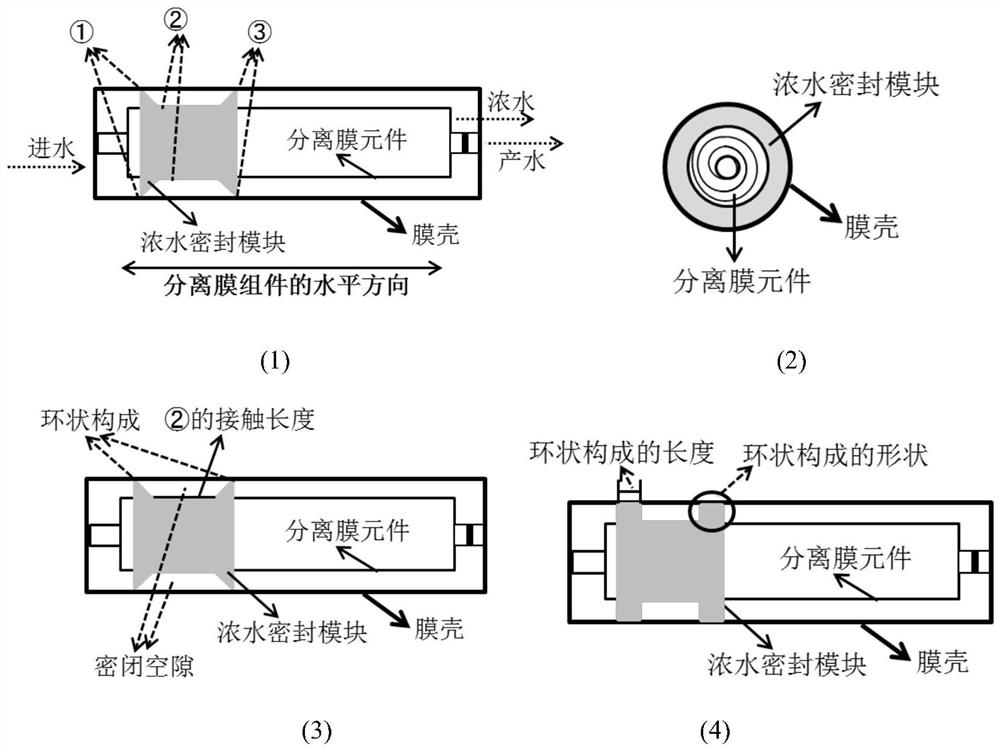

[0035] Such as figure 1 The separation membrane module shown includes a membrane shell, a separation membrane element and a concentrated water sealing module. The concentrated water sealing module is composed of a concentrated water sealing ring. The concentrated water sealing module forms a closed gap after contacting the membrane shell. The contact methods of the membrane shell and the separation membrane element include in turn: closed contact with the membrane shell and separation membrane element (①), only closed contact with the separation membrane element (②), airtight contact with the membrane shell and membrane element (③), and ② The contact length with the separation membrane element is 0.9cm, the airtight gap formed between ① and ③ of the concentrated water sealing module has a porosity of 100%, and the ring shape of the concentrated water sealing module in contact with the membrane shell is triangular. The annular contact between the water sealing module and the me...

Embodiment 3

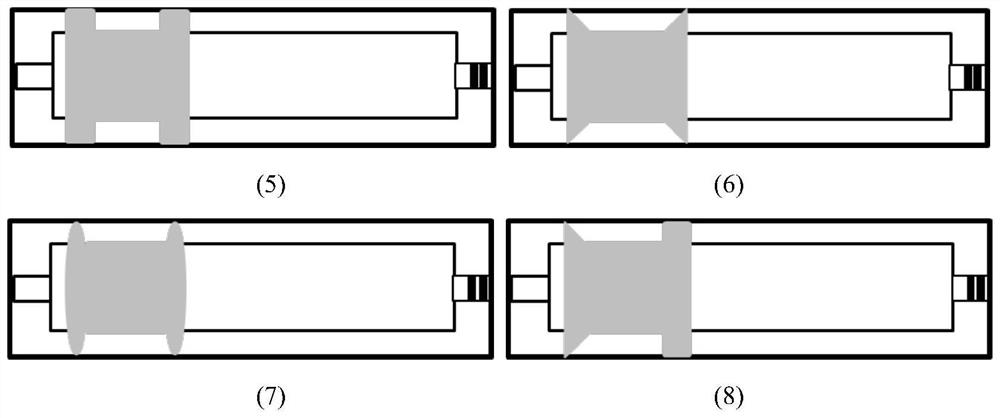

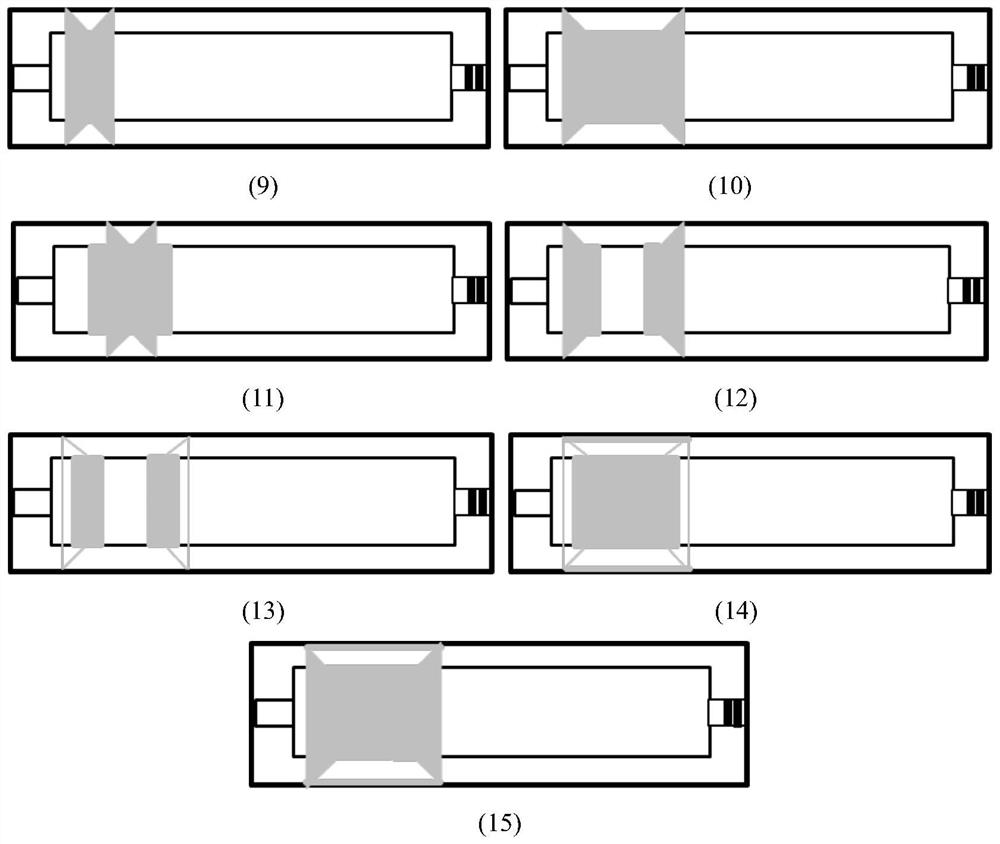

[0039] Compared with Example 1, the original parameters in the example are only different in the contact mode of ③ in the contact mode between the concentrated water sealing module and the separation membrane element and the membrane housing, and other original parameters are the same, and their specific values are shown in Table 1.

Embodiment 6

[0045] Compared with Example 4, the original parameters in the example are only different in the contact length between the concentrated water sealing module and the separation membrane element and the membrane housing (2) and the contact length with the separation membrane element, and the other original parameters are the same, and the specific values are shown in the table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com