Anti-frosting fresh air heat recovery device

A new air heat recovery and anti-frost technology, applied in the field of building environment and equipment engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

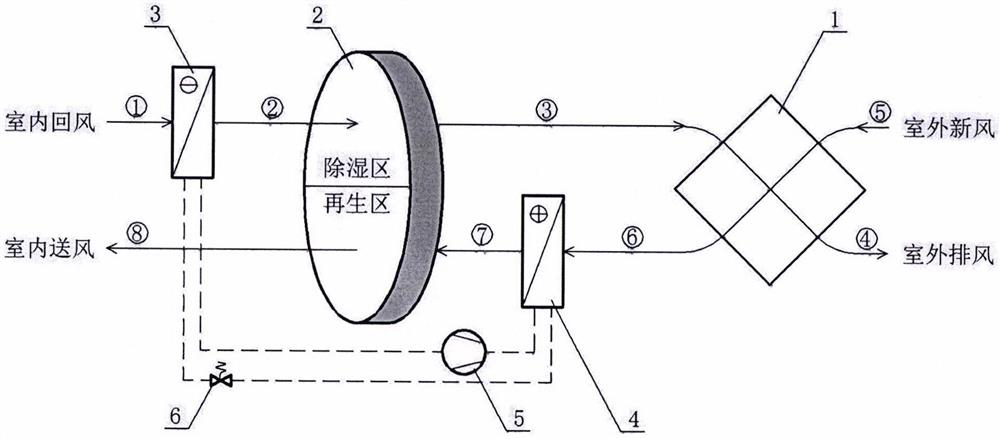

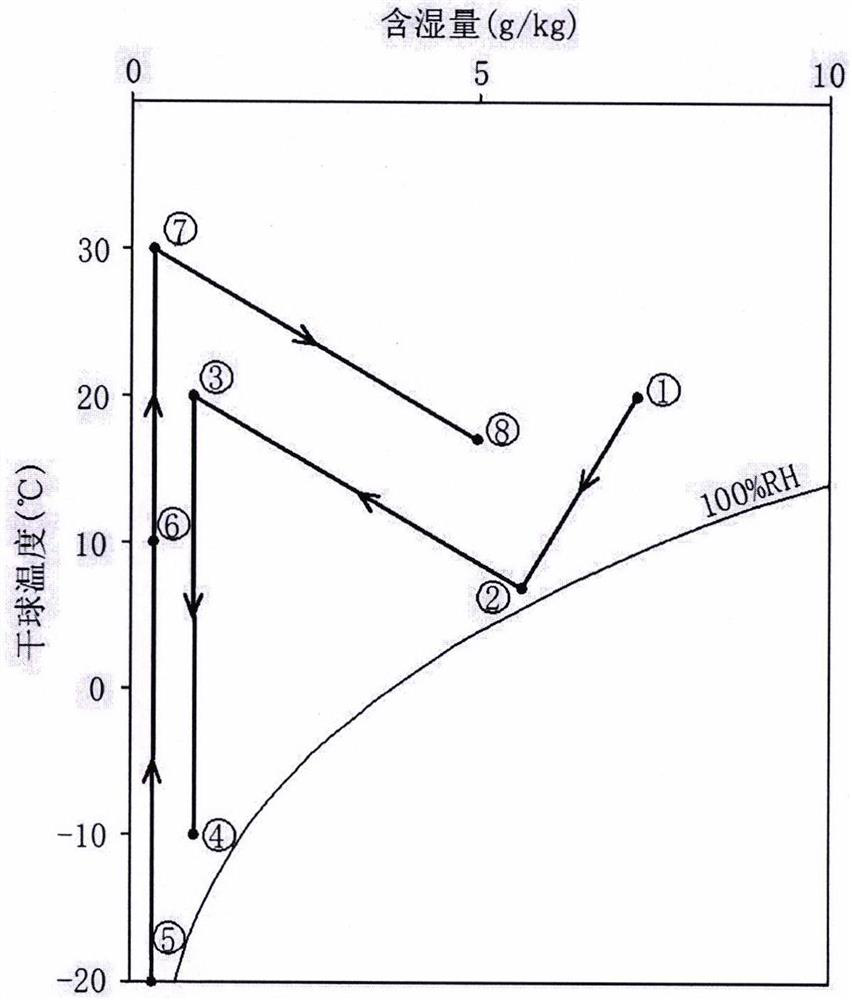

[0009] For the exhaust side, the indoor return air (status point ①) reaches the state point ② after being pre-cooled by the heat pump evaporator (3), then flows through the dehumidification zone of the dehumidification wheel (2) and reaches the state point ③ after being heated and dehumidified. After passing through the heat recovery core (1) and exchanging heat with the outdoor fresh air, the temperature drops to the state point ④ and is discharged outside.

[0010] For the fresh air side, the outdoor fresh air (status point ⑤) reaches the state point ⑥ after the heat exchange between the heat recovery core (1) and the exhaust air, and then reaches the state point ⑦ after being reheated by the heat pump condenser (4). Then flow through the regeneration zone of the dehumidification wheel (2) to cool and humidify, reach the state point ⑧ and send it into the room.

[0011] The evaporator (3), condenser (4), compressor (5), and throttling device (6) constitute a complete heat pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com