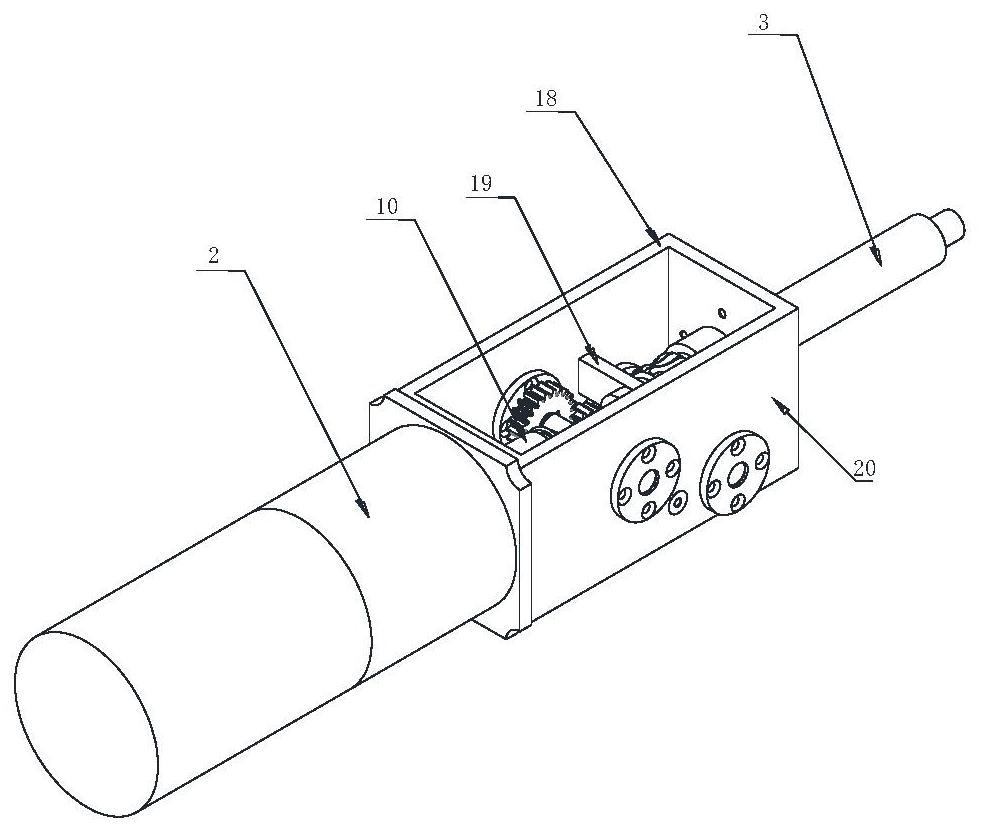

A three-dimensional textile driving system

A drive system and textile technology, applied in textiles, textiles, papermaking, looms, etc., can solve problems such as complex structural design and unstable transmission, and achieve the effect of simple structure, stable rotation, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solution, and advantages of the embodiments of the present invention more clear, the defect management mode in the embodiments of the present invention will be described in detail below in conjunction with the drawings in the embodiments of the present invention.

[0036] At present, when three-dimensional three-dimensional spinning is carried out, the fiber yarn is spun according to the set route mainly by continuously moving the yarn carrier. Three-dimensional three-dimensional textile equipment often needs to be provided with a drive system to drive the yarn carrier to move. Different three-dimensional textile equipment often has different drive systems, and the methods used by these drive systems to drive the yarn carrier to move are also different. In the driving system, the movement of the yarn carrier is mainly realized by arranging a driving gear and a driven gear, or arranging a gear and a rack. However, in some drive sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com