A kind of multi-effect rectification system and method of n-methylpyrrolidone

A multi-effect rectification and rectification technology, which is applied in the field of N-methylpyrrolidone multi-effect rectification system, can solve the problems of unsatisfactory refining effect and high energy consumption, so as to improve energy saving, rectification efficiency, and heat coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

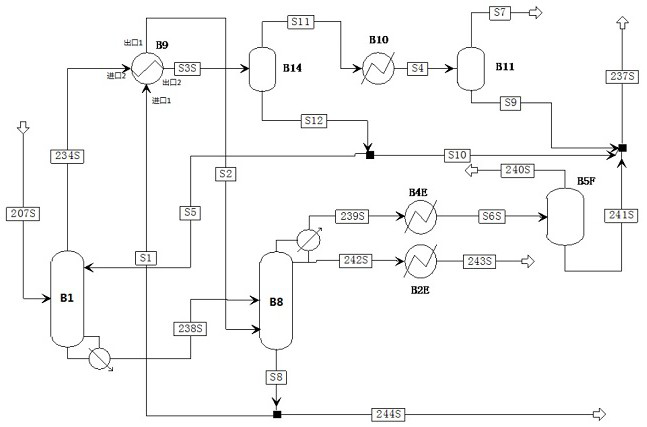

[0066] The present invention will be further described below with reference to the accompanying drawings and specific embodiments:

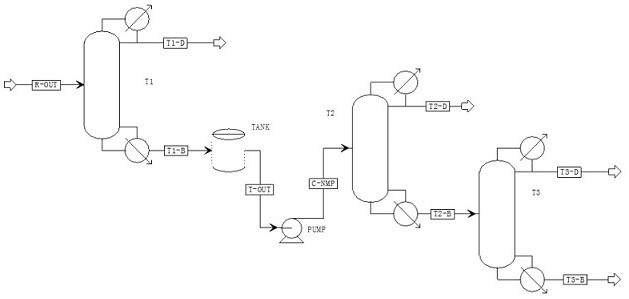

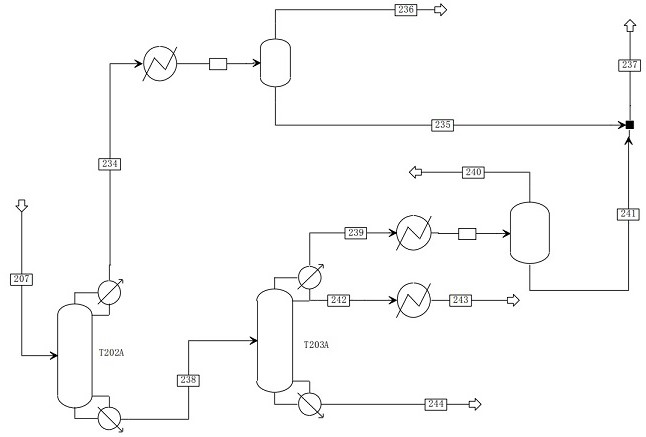

[0067] like image 3 As shown, an NMP multi-effect rectification system includes the following device:

[0068] Negative pressure dewatering tower B1, negative pressure dehydrated tower reboiler; NMP rectification tower B8, NMP rectification tower top condenser; and effect heat exchanger B9, material imports 1 and 2 and material outlet 1 And 2; gas-liquid separation devices B14 and B11 and condenser B10; gas-liquid separation device B5F; condenser B2e and condenser B4E.

[0069] The above device is connected as follows:

[0070] The tower of the negative pressure dewatering tower B1 is connected to the material inlet of the NMP rectification tower B8 by the negative pressure dewatering tower. NMP rectification is carried out in the middle of the NMP rectification column B8;

[0071] The tower exit of the NMP rectification tower B8 is divided into two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat load | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com