Grid flocculation sedimentation tank filled with diatomite

A technology of grid flocculation and sedimentation tank, which is applied in the direction of flocculation/sedimentation water/sewage treatment, water treatment parameter control, chemical instruments and methods, etc. Unstable water quality and other problems, to achieve the effect of saving dosage, saving dosage, and easy precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

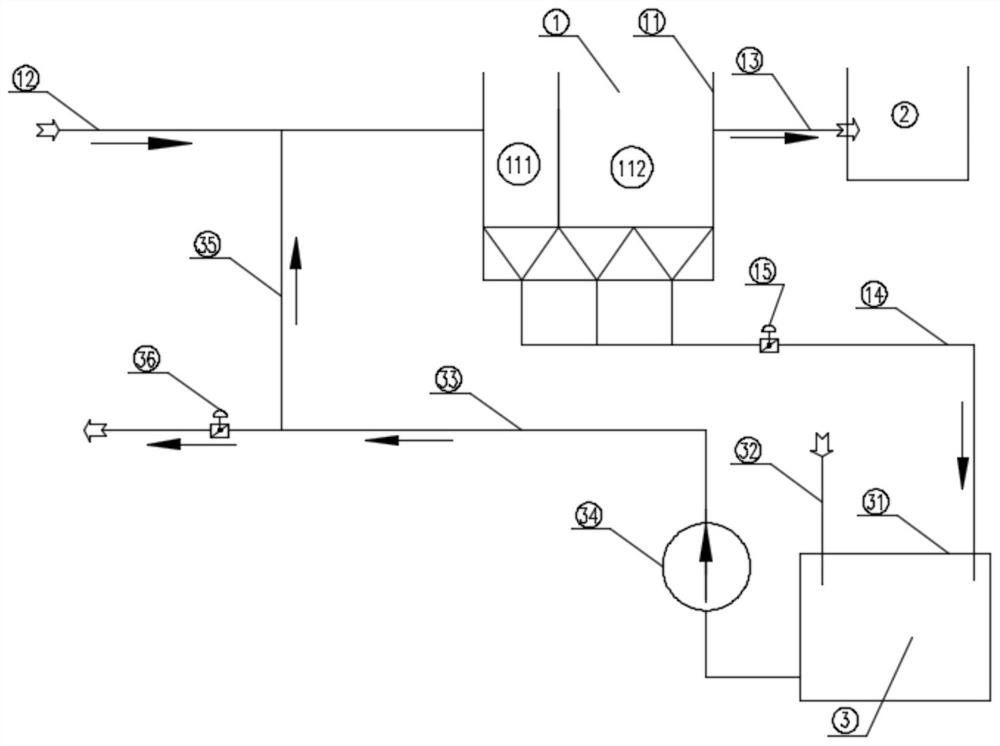

[0037] like figure 1 As shown, a grid flocculation sedimentation tank adding diatomite includes a grid flocculation sedimentation tank 1, a water production tank 2 connected to the grid flocculation sedimentation tank 1, and a sludge circulation tank 3.

[0038] The grid flocculation sedimentation tank 1 includes a grid flocculation sedimentation tank body 11, and the grid flocculation sedimentation tank body 11 includes a flocculation zone 111 and a sedimentation zone 112 arranged in the drainage direction of the flocculation zone 111;

[0039] The grid flocculation sedimentation tank 1 also includes a water inlet pipe 12 arranged on one side of the grid flocculation sedimentation tank body 11, and a water production pipe 13 arranged on the upper part of the grid flocculation sedimentation tank body 11 on the opposite side of the water inlet pipe 12. The bottom of the grid flocculation sedimentation tank body 11 is a main mud discharge pipe 14 formed by several branches of mu...

Embodiment 2

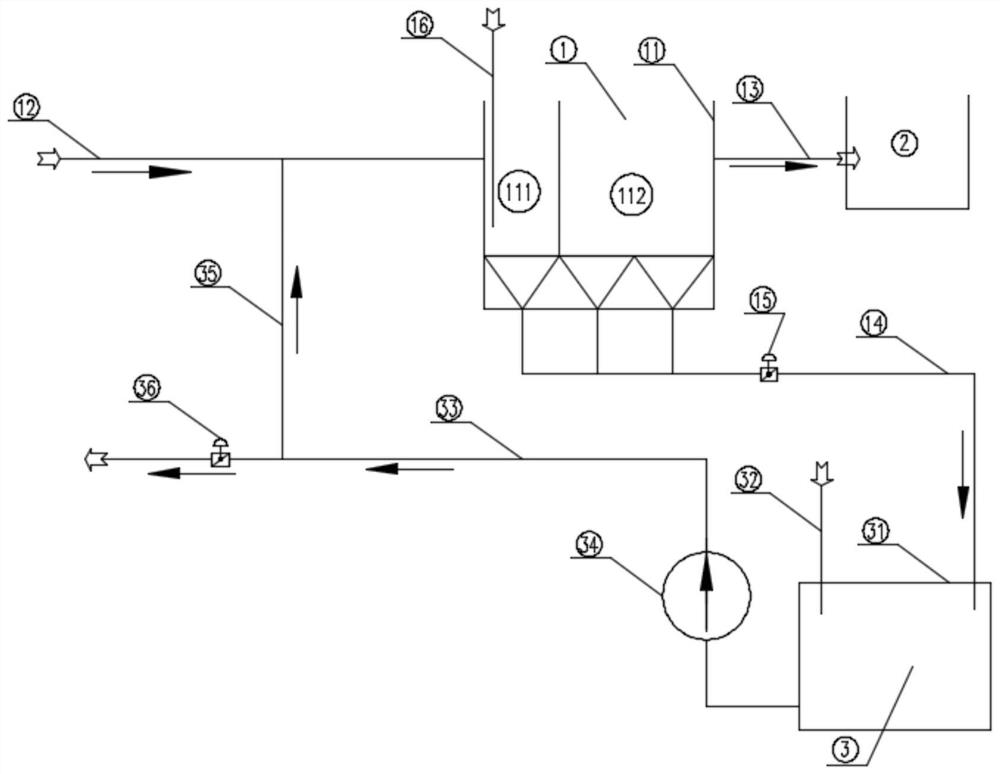

[0044] like figure 2 As shown, a grid flocculation sedimentation tank adding diatomite includes a grid flocculation sedimentation tank 1, a water production tank 2 connected to the grid flocculation sedimentation tank 1, and a sludge circulation tank 3.

[0045] The grid flocculation sedimentation tank 1 includes a grid flocculation sedimentation tank body 11, and the grid flocculation sedimentation tank body 11 includes a flocculation zone 111 and a sedimentation zone 112 arranged in the drainage direction of the flocculation zone 111;

[0046] The grid flocculation sedimentation tank 1 also includes a water inlet pipe 12 arranged on one side of the grid flocculation sedimentation tank body 11, and a water production pipe 13 arranged on the upper part of the grid flocculation sedimentation tank body 11 on the opposite side of the water inlet pipe 12. The bottom of the grid flocculation sedimentation tank body 11 is the main mud discharge pipe 14 formed by several branches of...

Embodiment 3

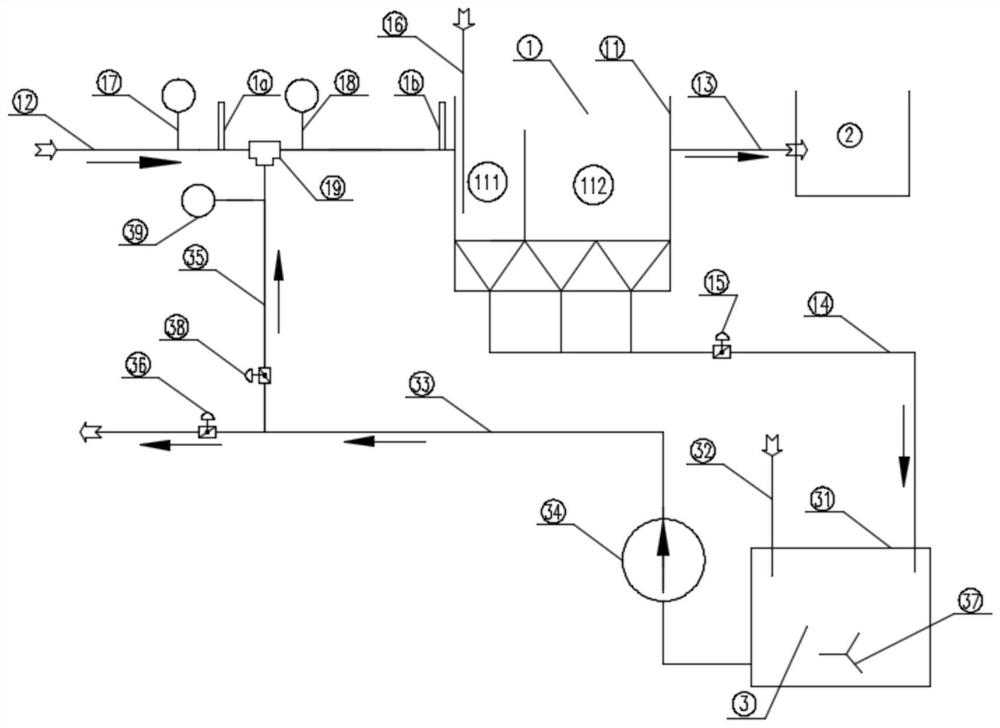

[0051] like image 3 As shown, a grid flocculation sedimentation tank adding diatomite includes a grid flocculation sedimentation tank 1, a water production tank 2 connected to the grid flocculation sedimentation tank 1, and a sludge circulation tank 3.

[0052] The grid flocculation sedimentation tank 1 includes a grid flocculation sedimentation tank body 11, and the grid flocculation sedimentation tank body 11 includes a flocculation zone 111 and a sedimentation zone 112 arranged in the drainage direction of the flocculation zone 111;

[0053] The grid flocculation sedimentation tank 1 also includes a water inlet pipe 12 arranged on one side of the grid flocculation sedimentation tank body 11. The water inlet pipe 12 is provided with a first flow meter 17 and a turbidity meter 18, and the water outlet of the first flow meter 17 is provided At one end of the water inlet of the turbidity meter 18, a tee 19 is provided on the water inlet pipe 12 between the first flow meter 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com