Clamping tool for loading and unloading oversized polycrystalline silicon rods

A super-large polysilicon, clamping tooling technology, applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problem of unbearable polysilicon rods, silicon rods detachment, cutting, etc., to achieve excellent structural performance and stable clamping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

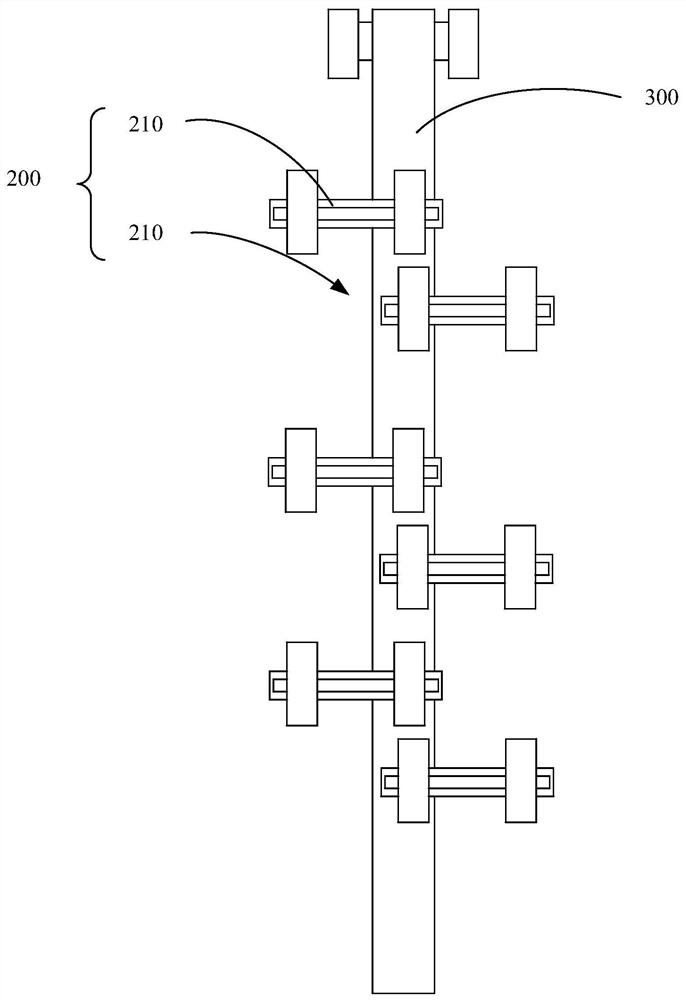

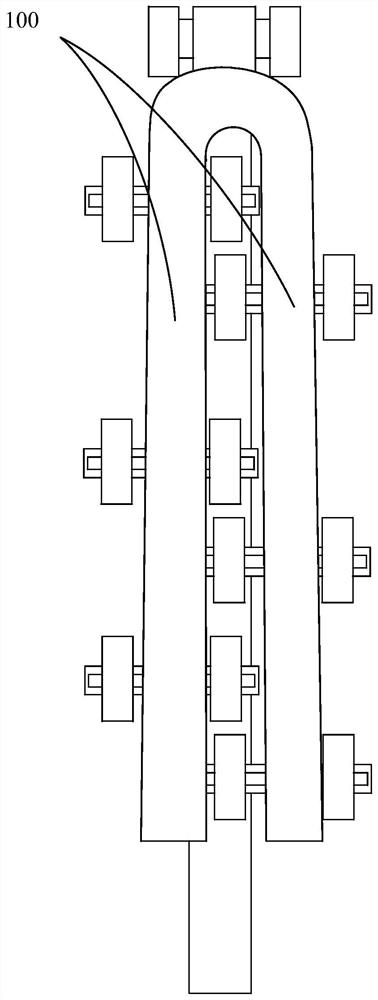

[0038] see figure 1 , figure 2 and image 3 , are respectively a structural schematic diagram of a clamping tool for loading and unloading super polysilicon rods provided in Embodiment 1, and a schematic diagram of clamping super polysilicon rods.

[0039]Among them, the polysilicon rod is mainly composed of two rod bodies 100 placed on the left and right sides, which are in a vertical state in the reduction furnace, and the clamping tool is mainly used to hold the polysilicon rod in the reduction furnace, and then Driven by the movable end 300 of the mechanical arm, it turns over to a horizontal state for conveying.

[0040] The clamping tooling in the present embodiment 1 includes a base (not shown), a mechanical arm (not shown) whose fixed end is connected to the base, and is arranged on the movable end of the mechanical arm in turn along the extension direction of the rod body 100. Several groups of clamping groups 200 on the 300; each group of clamping groups 200 incl...

Embodiment 2

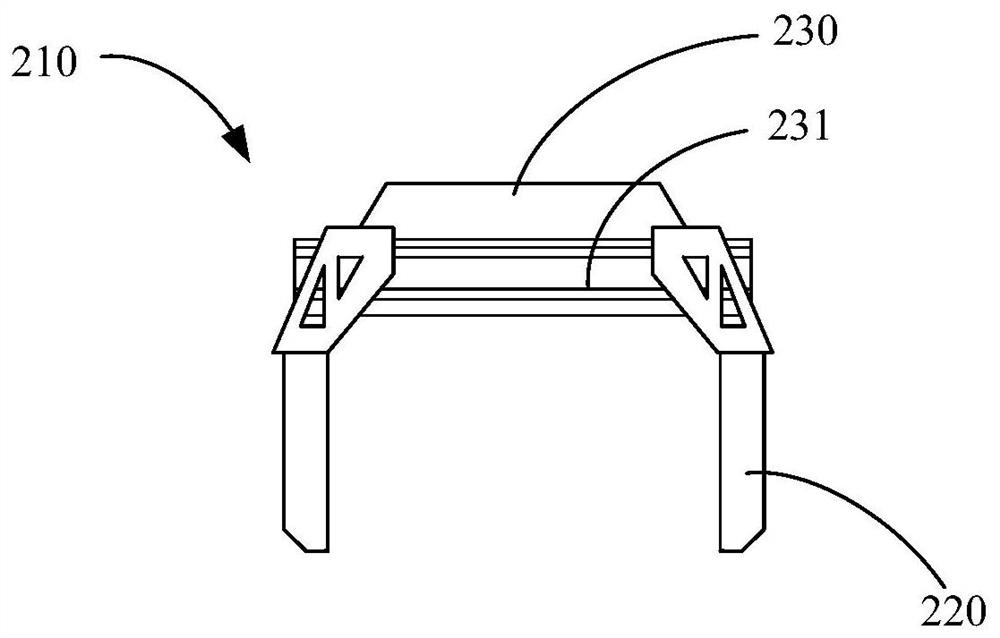

[0047] Embodiment 2 is substantially the same as Embodiment 1, and the main difference between the two lies in the structural details of the jaws 220 .

[0048] see Figure 4 to Figure 7 , in Embodiment 2, the jaw 220 is mainly composed of a moving steel frame for sliding connection with the first chute 231, and an elastic contact layer 222 for contacting the corresponding side wall of the rod body 100; A connecting plate 221 is formed on the moving steel frame, and the elastic contact layer 222 covers the connecting plate 221 and is fixedly connected to the connecting plate 221 by bolts. Compared with the clamping jaw 220 made of polyurethane material, the clamping jaw 220 is divided into a moving steel bar slidingly connected with the first chute 231 and an elastic contact layer 222 specially used for contacting the rod body 100 According to the setting method, since the connecting plate 221 on the moving steel frame is a steel structure, its stability and reliability are m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com