An intelligent winch and its control method

A hoist and intelligent technology, applied in the field of hoist, can solve the problems of wire rope winding disorder, loose winding, and large safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

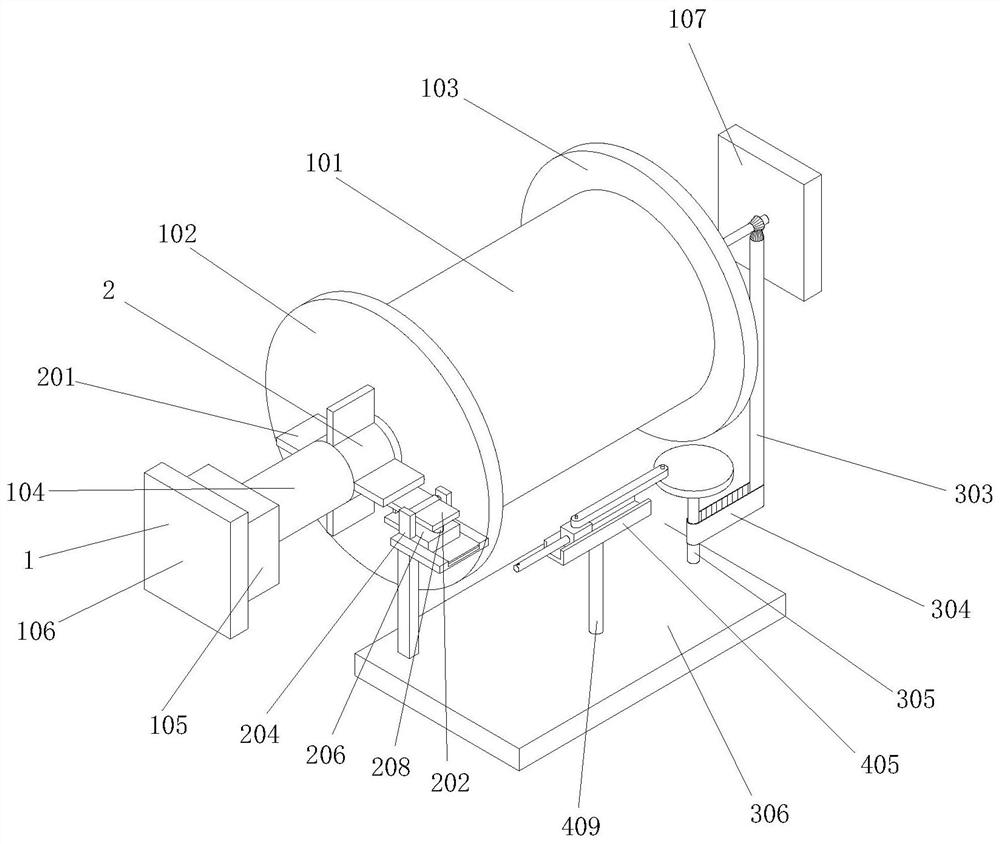

[0028] Embodiment: An automatic slope-adjusting gantry crane, as shown in Fig. 1-Fig. Including the roller shaft 101, the rear surface of the roller shaft 101 is fixedly connected with the roller plate 1 102, the front surface of the roller shaft 101 is fixedly connected with the roller plate 2 103, the rear end of the roller shaft 101 is fixedly connected with the output shaft 104, and the rear surface of the output shaft 104 is fixedly connected There is a motor 105, the rear surface of the motor 105 is fixedly connected with a side plate 106, and the front end of the output shaft 104 is movably connected with a side plate 2 107.

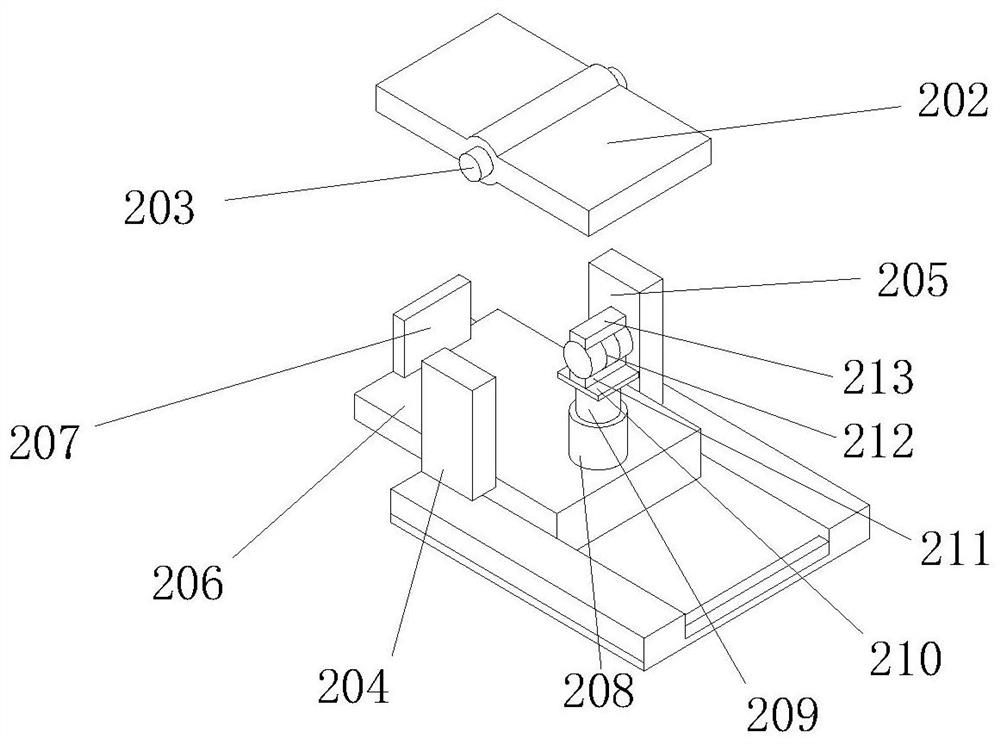

[0029]The rear end of the output shaft 104 is fixedly connected with an anti-falling device 2. The anti-falling device 2 includes a rotating plate 201. The lower surface on the right side of the rotating plate 201 is fitted with a turning plate 202. The middle part of the rear surface of the turning plate 202 is movable and internally connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com