Lightweight anti-static foam pump and material production process thereof

A foam pump and anti-static technology, which is applied to sealing parts with unloading devices, closing, packaging, etc., can solve the problems of lack of double-piston and connecting seat structural design, material production process needs to be improved, and poor overall structural design, etc. , to achieve the effects of good sealing, convenient production, and small space occupation of pump body height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

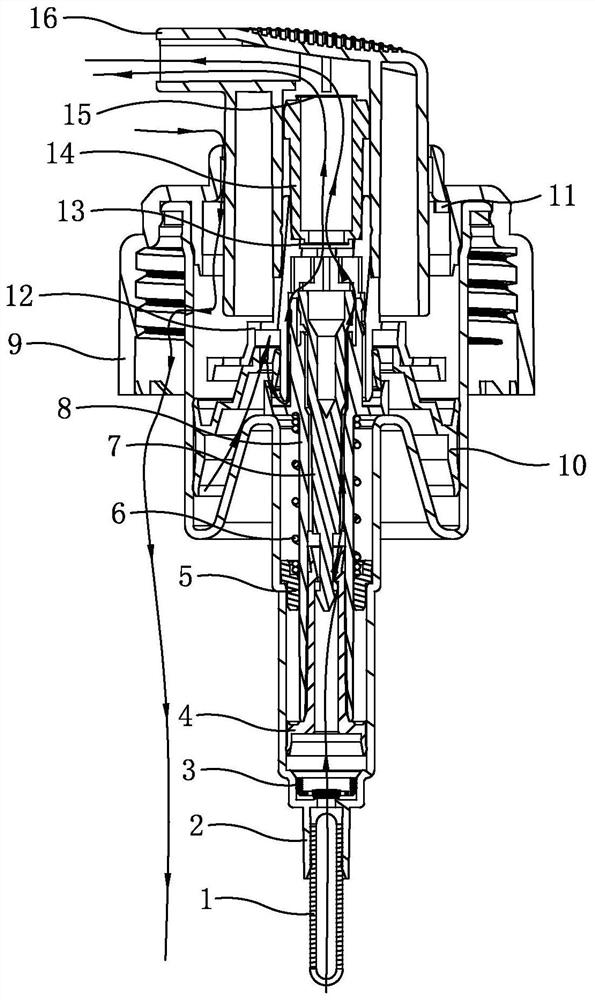

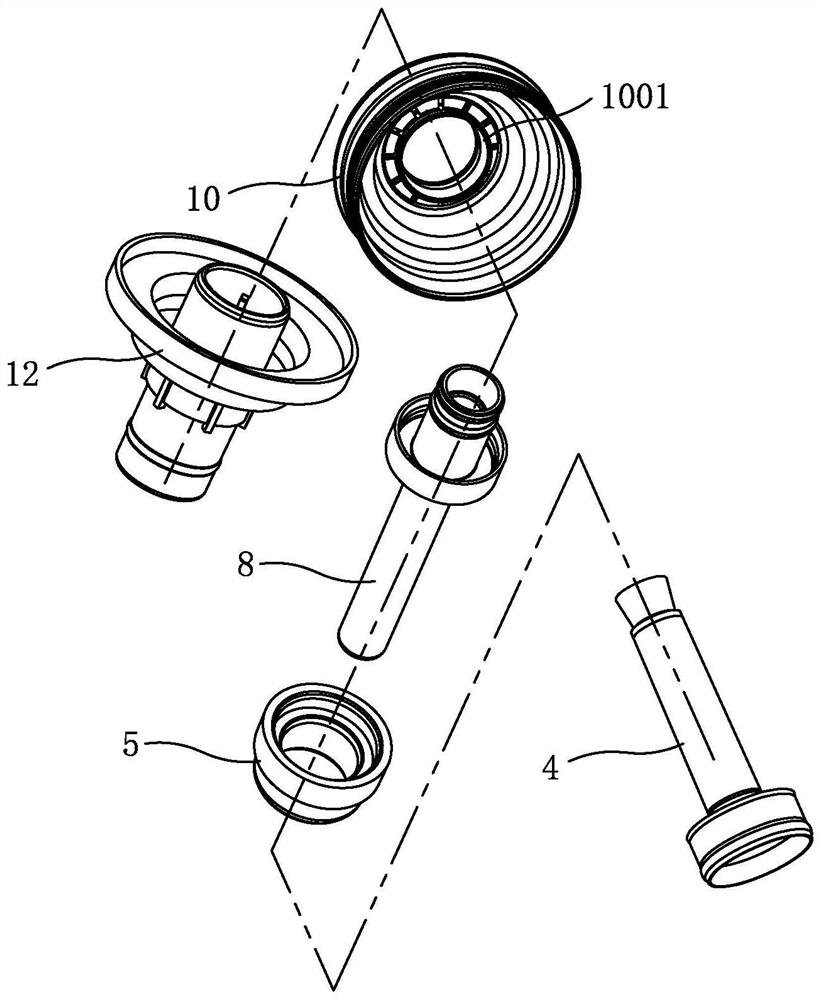

[0020] Now in conjunction with accompanying drawing, the present invention will be further described. Such as Figure 1-Figure 6 As shown, the outer diameter of the inner ring diameter of the large ring 9 of the foam pump is sleeved in the inner diameter of the pump port of the pump body 2, and at the same time the outer diameter of the pump port of the pump body and the inner ring diameter of the large ring fit together with the ribs, and the fitting place A gasket 11 is provided, and the pump body is provided with a piston, a spring pad 5, a connecting seat 12, a valve stem 8, a valve needle 7, a spring 6 and an elastic sleeve 3, and the elastic sleeve is arranged at the water inlet hole in the pump body. The water inlet hole is provided with a suction pipe 1, and the shrapnel in the middle of the bullet sleeve is against the orifice of the water inlet hole in the pump body. The valve stem protruding from the pump body is connected to the duckbill 16 through the connecting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com