Steel pipe end grooving device

A technology for steel pipes and mounting brackets, applied in positioning devices, clamping devices, clamping, etc., can solve the problems of wasting manpower, easy cutting and skewing, and different slotting depths, and achieve the effect of improving work quality and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

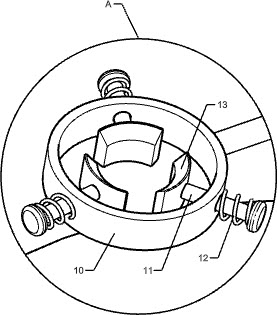

[0020] A steel pipe end grooving device, such as Figure 1-5 As shown, it includes a mounting frame 1, a slotting assembly and a rotating clamping assembly. The upper left side of the mounting frame 1 is provided with a slotting assembly that is slotted by sliding, and the left side of the mounting frame 1 is provided with a slotting assembly that is slotted by sliding. Clamped swivel clamp assembly.

[0021] When grooving the end of the steel pipe, the staff clamps the steel pipe that needs to be grooved by rotating the clamping device, and then the staff grooves the clamped steel pipe through the grooving device. While grooving, the staff rotates Rotate the clamping device to remove the slotted steel pipe for replacement. After the slotting is completed, close the slotting assembly.

[0022] Such as figure 1 As shown, the slotting assembly includes a guide rod 2, a sliding sleeve 3, a first spring 4, a first installation block 5, a handle 6 and an electric cutting knife 7,...

Embodiment 2

[0027] On the basis of Example 1, such as figure 1 , 3 , 4 and 5, also includes guide sleeve 14, L-shaped slide bar 15, third spring 16, square block 17, push block 18, second mounting block 19, wedge-shaped teeth 20, torsion spring 21, second rotating shaft 22, ratchet 23, the first bevel gear 24 and the second bevel gear 25, the guide sleeve 14 is welded on the top of the installation disk 8, and the inner sliding type of the guide sleeve 14 is provided with an L-shaped slide bar 15, and the L-shaped slide bar 15 and the guide sleeve A third spring 16 is wound around the 14, a square block 17 is welded to the right end of the L-shaped slide bar 15, and a push block 18 is welded on the rear side sliding sleeve 3, and the push block 18 cooperates with the square block 17, and the bottom of the L-shaped slide bar 15 The end is welded with a second mounting block 19, and the second mounting block 19 is evenly spaced and rotated to be provided with six wedge-shaped teeth 20, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com