Strip electrode submerged arc build up welding equipment

A submerged arc surfacing and strip electrode technology, which is applied in arc welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unbalanced heating state of welding strips, poor weld formation, and high adjustment requirements for commissioning personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

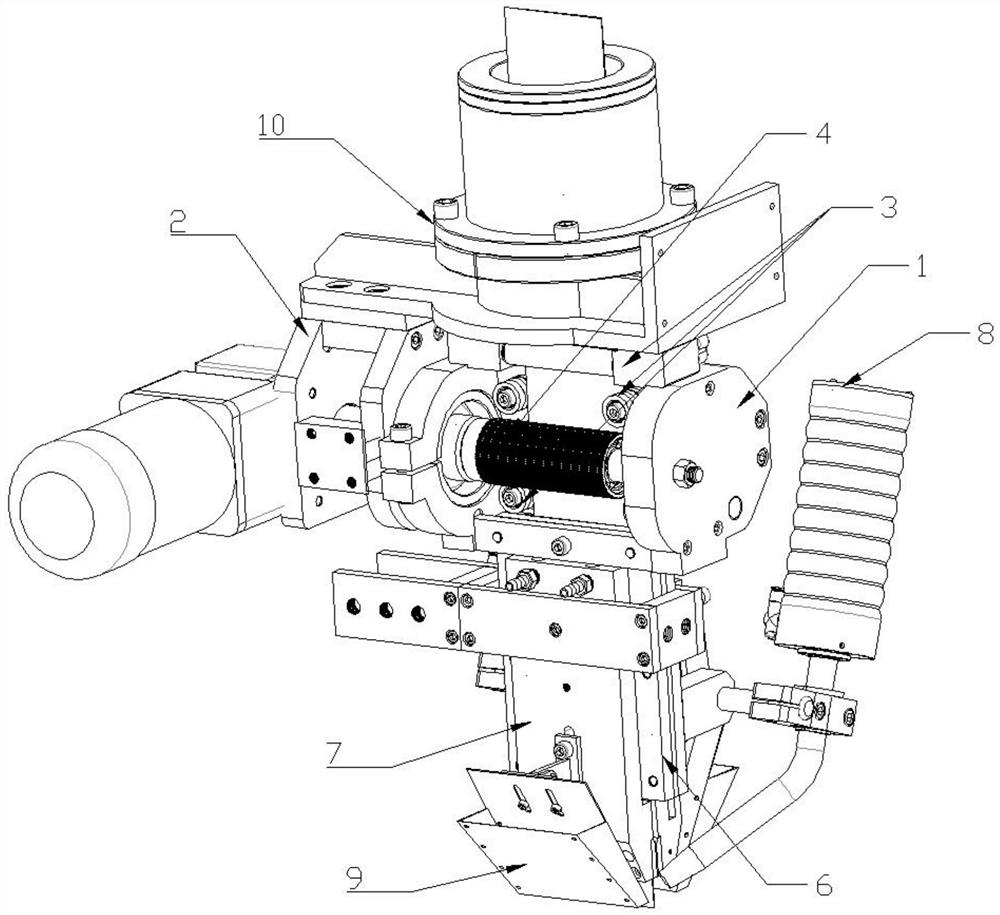

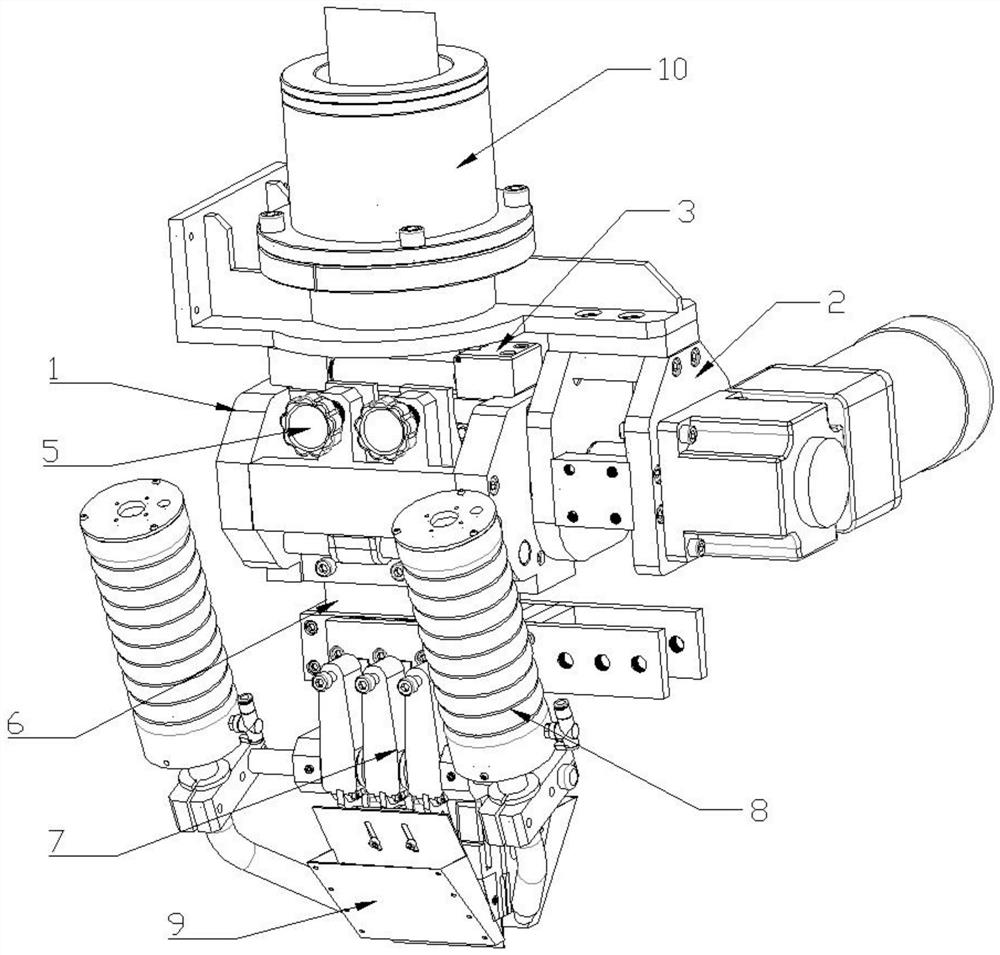

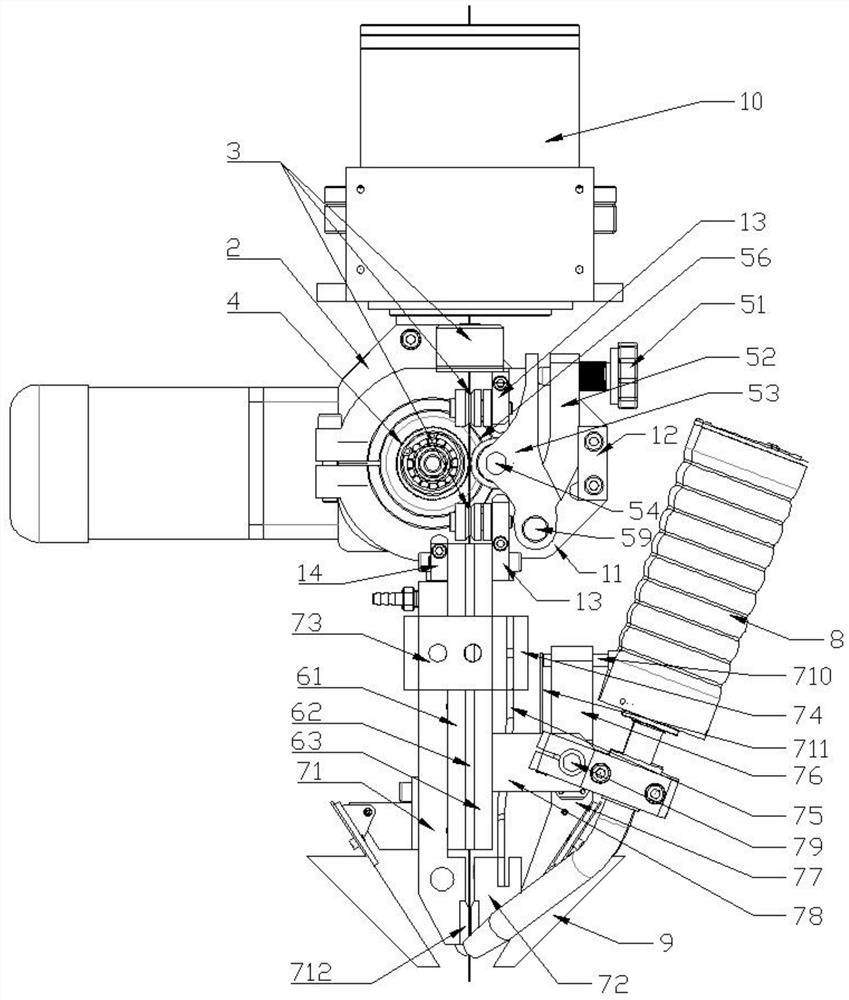

[0102] A strip submerged arc surfacing equipment, the machine head mounting seat is divided into upper and lower parts that can be rotated relatively, which can make the belt submerged arc surfacing welding machine head and random head mounting seat rotate to realize the 90° twist of the welding strip and realize two parts. Overlay welding in one direction, such as Figure 1-Figure 13 As shown, specifically set to the following structure:

[0103] It includes a machine head mounting base 10 and a belt submerged arc surfacing machine head. The belt electrode submerged arc surfacing machine head includes a pulley assembly 3, a belt box assembly 6, a machine base assembly 1, a hanger assembly 2, and a motor drive Assembly 4, geared motor, pressing wheel assembly 5 and contact tip assembly 7.

[0104] The machine head mounting base 10 includes a connecting base and an insulating cylinder 103. The connecting base has an inner hole straight through up and down. The connecting seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com