a twisting machine

A wire twisting machine and wire clamping technology, which is applied in the field of wire twisting machines, can solve problems such as troublesome core wires requiring manual operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

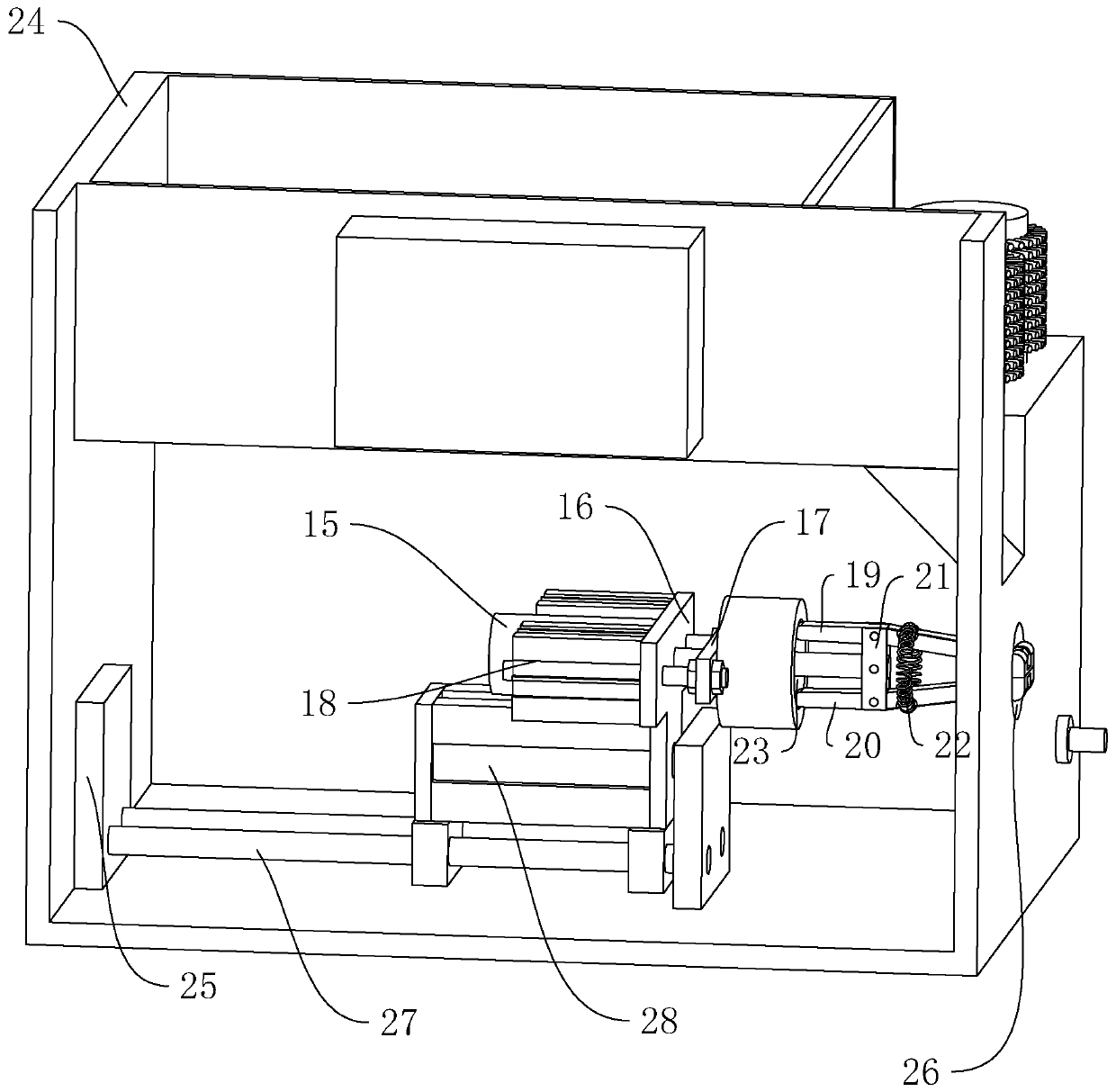

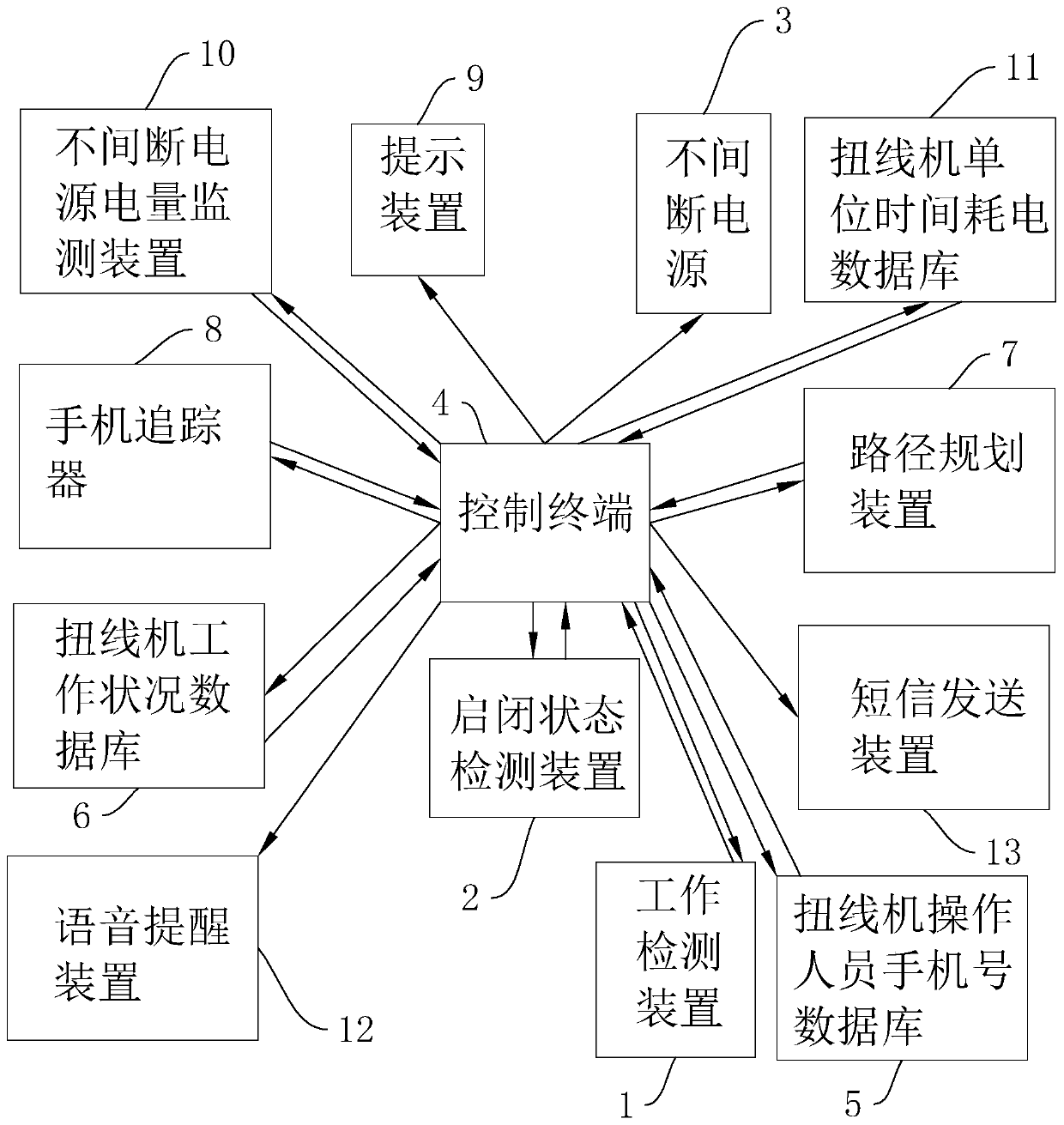

[0035] refer to figure 1 , The twisting machine includes a clamping assembly, a driving motor 15, a mounting base plate 16, an adjusting plate 17 and a jaw adjusting cylinder 18.

[0036] Wherein, the clamping assembly includes a first clamping arm 19, a second clamping arm 20, a pivot seat 21, an elastic element 22 and a tapered cavity structure 23; the middle sections of the first and second clamping arms are respectively pivoted On the pivotal seat 21, the first and second clamping arms are separated at both ends of the pivotal seat 21 to form a clamping section for clamping wires and an operating section for controlling the opening and closing of the clamping section. The element 22 adopts a pressure spring, and the two ends of the pressure spring are respectively connected to the two clamping sections. Of course, it can also be designed as other convent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com