Concrete paver for U-shaped water channel construction

A paver and concrete technology, which is applied in the field of concrete paver for U-shaped water channel construction, can solve the problems of unusable and difficult construction of U-shaped water channel, and achieve the goal of improving flatness, rolling performance and impact strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the instructions and the accompanying drawings. The specific connection methods of each part adopt mature bolts, rivets, welding in the prior art , pasting and other conventional means, no longer described in detail here.

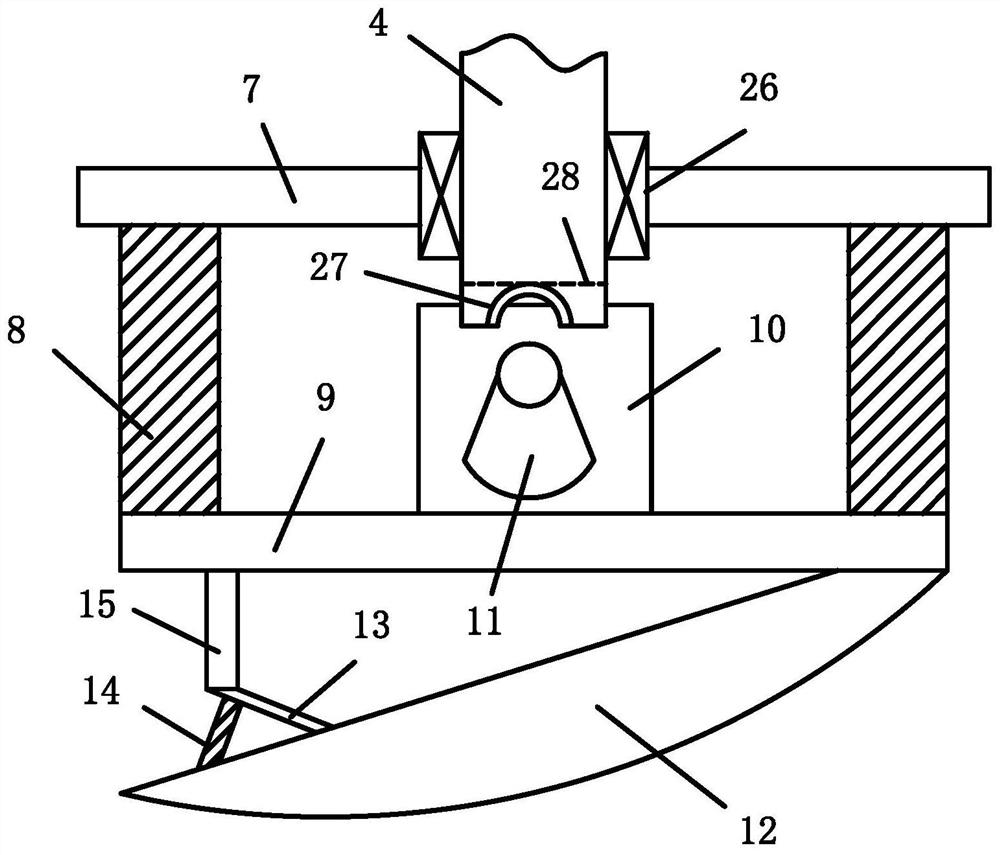

[0017] refer to Figure 1-3 , a specific embodiment of the present invention includes a paver main body 1, the two sides of the paver main body 1 are symmetrically equipped with a spray head 2, a U-shaped carriage 3 is installed on the paver main body 1, and a U-shaped carriage 3 A telescopic rod 4 is slidingly installed inside, and the outer end of the telescopic rod 4 is fixed with a vibrator 5, and the inner end of the telescopic rod 4 is connected with the swing cylinder 6, and the swing cylinder 6 is installed on the paver main body 1; the vibrator 5 includes The substrate 7 connected with the telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com