Full-rotational-flow supersonic separation device

A separation device and supersonic technology, applied in swirl devices, devices whose axial direction of swirl remains unchanged, separation methods, etc., can solve the problem of inability to realize the free collocation of shrinkage section and diffuser section, narrow adaptability to working conditions, Difficult processing and other problems to achieve the effect of reducing the impact of re-evaporation of droplets, ensuring separation effect and separation efficiency, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

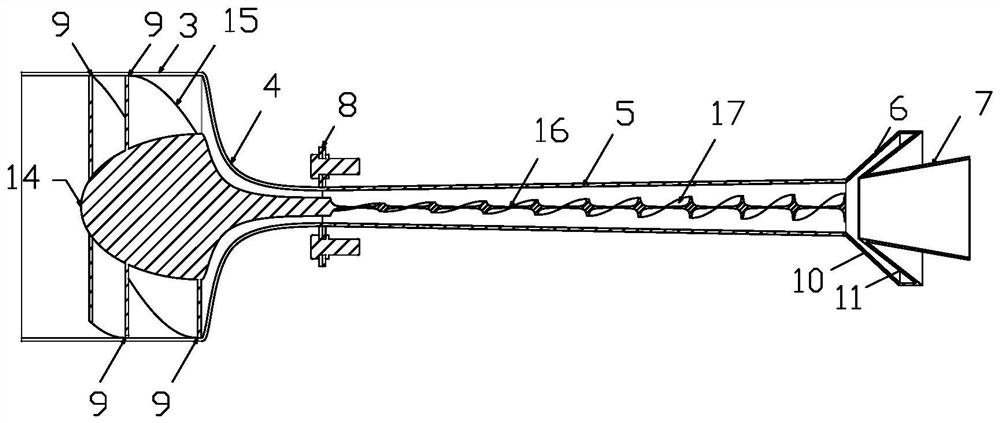

[0059] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

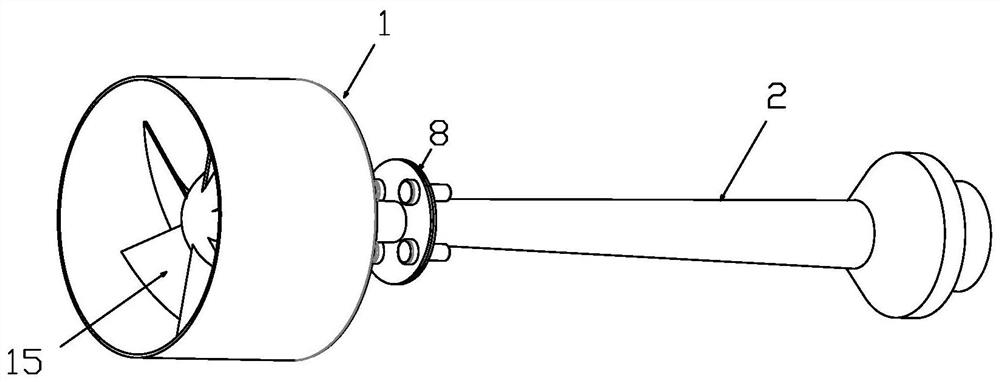

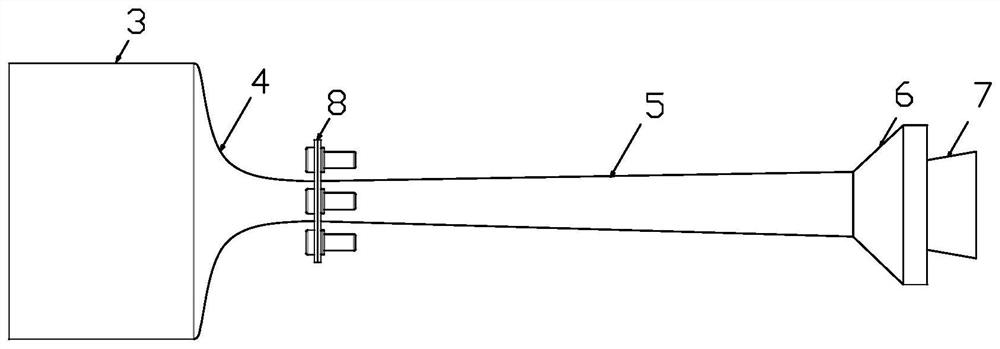

[0060] Such as figure 1 As shown, a full-swirl supersonic separation device includes a shell and a central swirl component. Among them, the shell includes a steady flow constriction section 1 and a diffuser separation section 2 connected in sequence, such as figure 2 shown.

[0061] definition figure 1 The left end is the front end of the separation device, and the steady flow contraction section 1 is located at the front side of the diffuser separation section 2.

[0062] The central swirl part is located in the shell, that is, in the steady flow constriction section 1 and the diffuser separation section 2 .

[0063] The steady flow constriction section 1 includes a straight pipe steady flow section 3 and a Laval nozzle tapering section 4 .

[0064] The steady flow section 3 of the straight pipe is located at the front side of the taperin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com