Multi-layer net-shaped wood pallet feeding device and method

A wooden pallet and mesh technology, which is applied in the field of multi-layer mesh wooden pallet feeding device, can solve the problems of low dimensional accuracy, rough manufacturing process of multi-layer mesh wooden pallets, and different shapes, so as to reduce labor intensity, Easy operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides a multi-layer net-shaped wooden pallet feeding device, including a bridge assembly 1 and a transverse assembly 2. The transverse assembly 2 is provided on the bridge assembly 1 and the two are slidingly connected. The moving assembly 2 clamps the wooden pallet 3, and the horizontal moving assembly 2 can drive the wooden pallet 3 to move up and down and laterally.

[0050] The bridge assembly 1 is used to carry the weight of the horizontal movement assembly 2 and provide a passage for horizontal movement and lifting; the horizontal movement assembly 2 is used to realize the lifting, the horizontal movement along the bridge assembly 1 and the clamping and clamping opening of the wooden pallet 3 Adjustment.

[0051] Specifically, the working process or application process provided by this embodiment is as follows:

[0052] The upstream wooden pallet 3 conveying equipment transports the wooden pallet stack 8 to the bottom of the bridge assembly 1, and the...

Embodiment 2

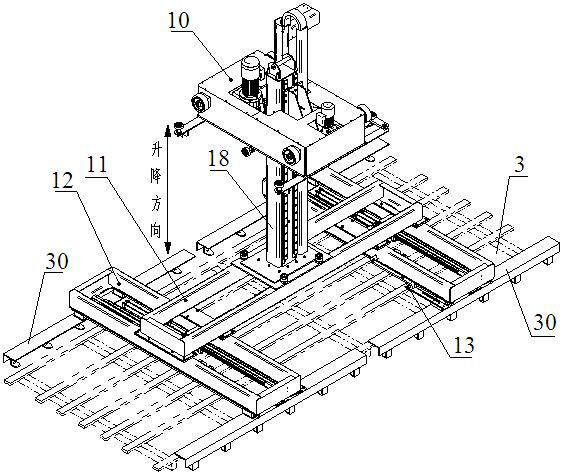

[0054] On the basis of embodiment 1, this embodiment provides a multi-layer net-shaped wooden pallet feeding device. The transverse assembly 2 includes a transverse main body 10, a beam assembly 11, a clamping unit 12 and a transverse drag chain 13. The traverse main body 10 and the clamping unit 12 are respectively fixed on the top and bottom of the beam assembly 11, and the traverse drag chain 13 is arranged on the side of the clamping unit 12.

[0055] The traversing main body 10 implements traversing and lifting actions, the beam assembly 11 is used to expand the number of clamping units 12, and the clamping unit 12 is used to implement clamping actions.

[0056] Such as image 3 As shown, the transverse beam assembly 11 is installed under the traverse main body 10 to install the clamping unit 12. In this embodiment, there are two clamping units 12 so that it can handle two wooden pallet stacks 8 at the same time; The chain 13 is used to accommodate the air pipes and cables tha...

Embodiment 3

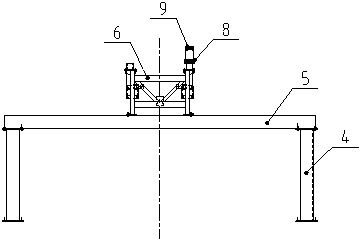

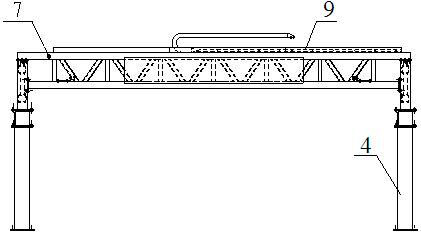

[0058] On the basis of embodiment 1 or 2, this embodiment provides a multi-layer net-shaped wooden pallet feeding device. The bridge assembly 1 includes a column 4, a beam 5, a large frame 7 and a small frame 6. The cross beam 5 is arranged between the two uprights 4 to form a gate structure. There are two gate structures, which are respectively arranged at the beginning and the end of the logistics transportation line of the wooden pallet stack 8;

[0059] The small frame 6 is fixed on the cross beam 5, and the large frame 7 is set between the small frames 6 and is two, which are respectively set on both sides of the small frame 6, and the small frame 6 and the large frame 7 form a horizontal movement Assemble 2 walking channel.

[0060] Such as figure 1 , figure 2 As shown, the combination of the column 4 and the beam 5 provides a door structure, which is convenient for the upstream wooden pallet 3 conveying equipment to transport the wooden pallet stack 8; two beams 5 are insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com