Continuous and automatic trimming equipment for barrel-shaped plastic part ports

A technology for trimming and plastic parts, which is applied in the field of continuous automatic trimming equipment for barrel-shaped plastic parts. It can solve the problems of manpower consumption, low trimming quality, and low trimming efficiency of plastic parts, and achieve high trimming efficiency. , Guarantee the quality of products and save labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

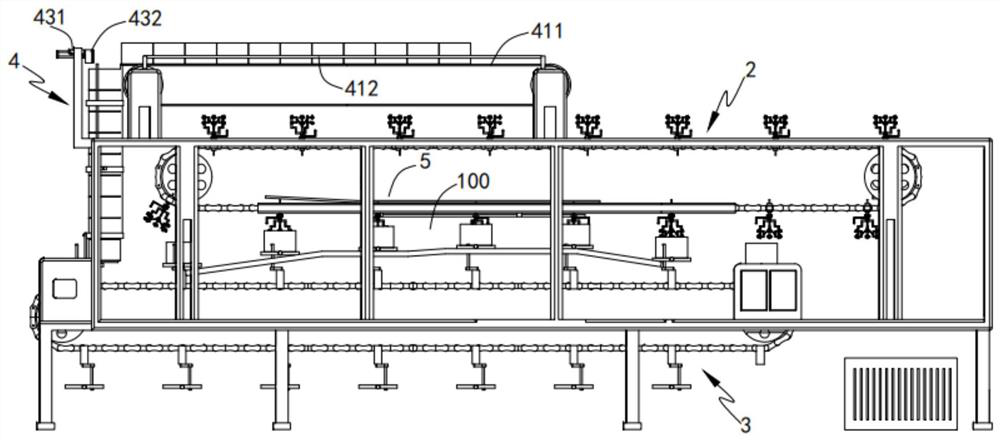

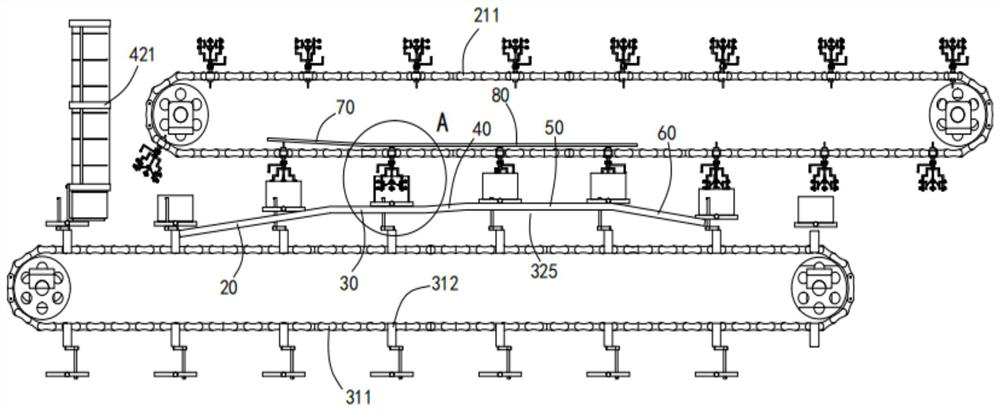

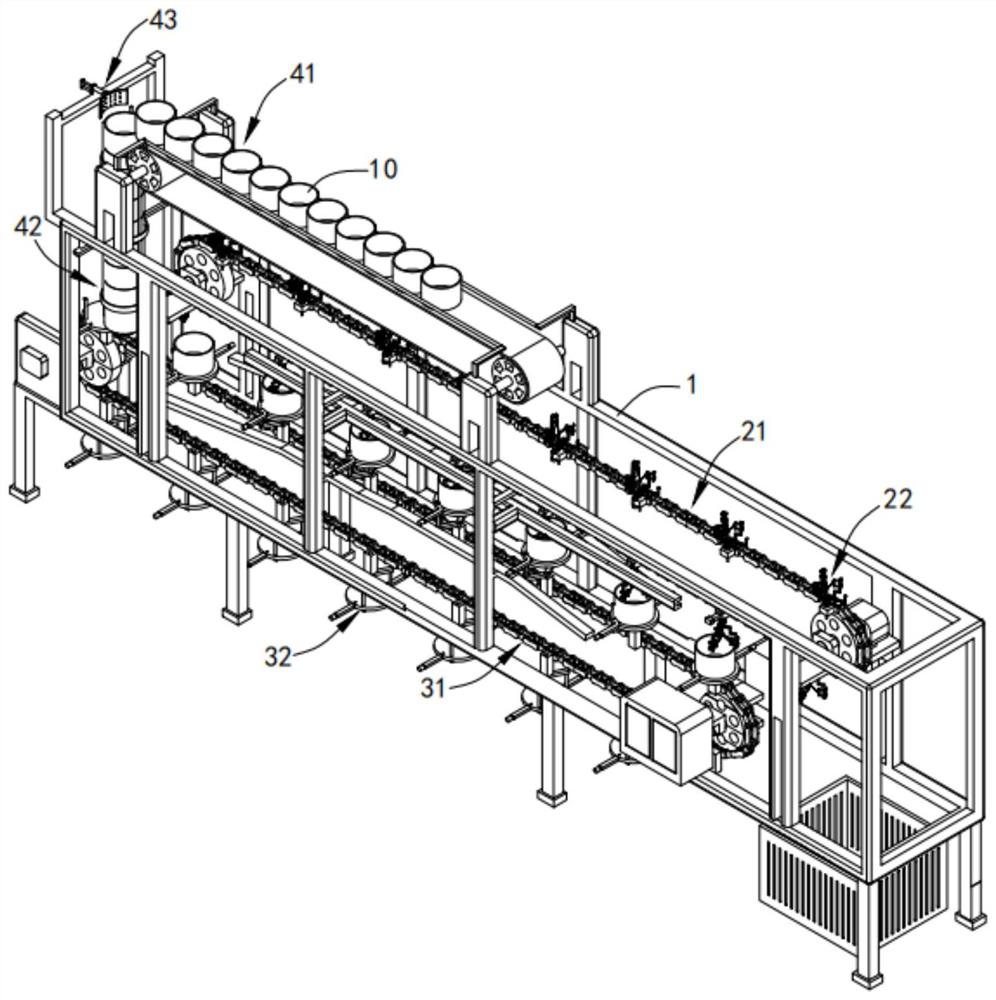

[0040] Such as Figure 1 to Figure 8As shown, a barrel-shaped plastic port continuous automatic trimming equipment, including a frame 1, the frame 1 is provided with a rotary trimming device 2 and a rotary support device 3, the rotary trimming device 2 and the rotary support The device 3 is arranged up and down, forming a trimming channel 100 between the two; the rotary trimming device 2 includes a rotary mechanism a21 and an array of trimming mechanisms 22 arranged on the rotary mechanism a21 and driven by the rotary mechanism a...

Embodiment 2

[0056] Such as figure 2 and Figure 8 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The feature is that: the feeding mechanism 41 includes a transmission belt 411 arranged on the frame 1, and both sides of the transmission belt 411 are provided with limit guide rods 412 fixed on the frame 1;

[0057] The feeding mechanism 42 includes a blanking frame 421 arranged vertically, a supporting plate 422 is provided at the lower end of the blanking frame 421, the supporting plate 422 is arranged in an L shape, and the plastic part 10 falls on the The upper end surface of the supporting plate 422 is lower than the lower bottom surface of the blanking rack 421 when it is on the supporting plate 422 ;

[0058] In this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com