Citrus fiber-containing black sesame normal-temperature yoghourt and preparation method thereof

A technology of citrus fiber and black sesame, which is applied to milk preparations, bacteria used in food preparation, dairy products, etc., can solve the problems of insufficient taste of yogurt at room temperature, nutritional quality stability during shelf life, etc., to improve shelf life stability, Improve stability and suppress allergies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

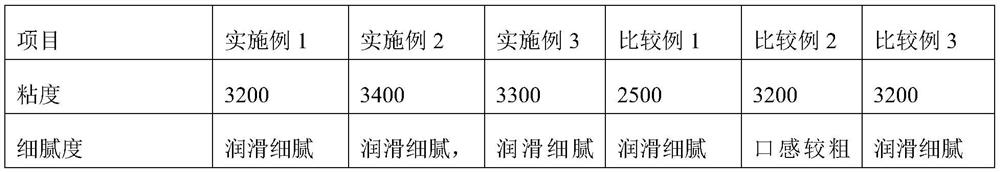

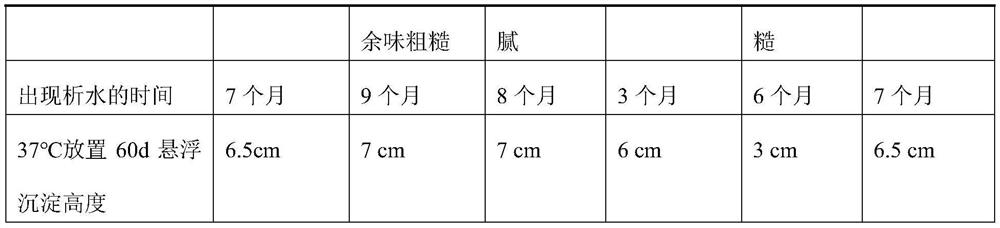

Examples

Embodiment 1

[0032] The preparation method of the black sesame normal temperature yoghurt containing citrus fiber of the present embodiment, the steps are as follows:

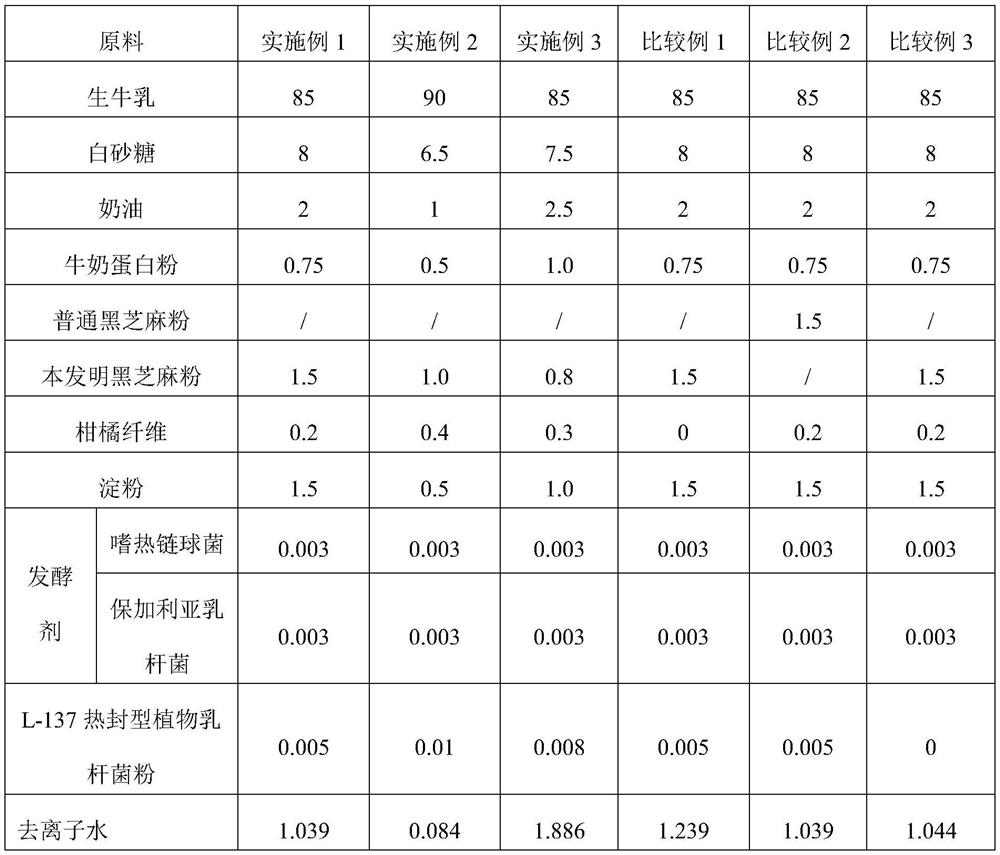

[0033] A, carry out proportioning by embodiment 1 in table 1, prepare materials;

[0034] B. Sterilize raw milk at 137°C for 5 seconds, then dissolve citrus fiber, starch, milk protein powder, black sesame powder, cream, and white sugar in raw milk at a temperature of 58°C. The time is 15min, adding deionized water to obtain the feed liquid;

[0035] C. Homogenize the feed liquid, the homogenization temperature is 58°C, the pressure is 20MPa, then sterilize at 95°C for 5 minutes, inoculate the starter, the fermentation temperature is 42°C, ferment to the end of fermentation, the end point of fermentation is pH4.3, and cool down to At 25°C, add L-137 heat-sealed Lactobacillus plantarum powder to obtain fermented milk, pasteurize the fermented milk at 75°C for 25 seconds, and fill it to obtain black sesame room temperature y...

Embodiment 2

[0040] A, carry out proportioning by embodiment 2 in table 1, prepare materials;

[0041] B. Sterilize raw milk at a temperature of 140°C for 3 seconds, then dissolve citrus fiber, starch, milk protein powder, black sesame powder, cream, and white sugar in raw milk at a temperature of 55°C. The time is 30min, adding deionized water to obtain the feed liquid;

[0042] C. Homogenize the feed liquid, the homogenization temperature is 60°C, the pressure is 18MPa, then sterilize at 90°C for 10 minutes, inoculate the starter, the fermentation temperature is 41°C, ferment to the end of fermentation, the end point of fermentation is pH4.4, and cool down to At 20°C, add L-137 heat-sealed Lactobacillus plantarum powder to obtain fermented milk, pasteurize the fermented milk at 72°C for 30 seconds, and fill it to obtain black sesame room temperature yogurt containing citrus fiber.

[0043] The black sesame powder described in step A, preparation method is as follows:

[0044] a. Remove...

Embodiment 3

[0047] A, carry out proportioning by embodiment 3 in table 1, prepare materials;

[0048]B. Sterilize the raw milk at a temperature of 138°C for 7 seconds, then dissolve citrus fiber, starch, milk protein powder, black sesame powder, butter, and white sugar in the raw milk at a temperature of 60°C. The time is 20min, adding deionized water to obtain the feed liquid;

[0049] C. Homogenize the feed liquid, the homogenization temperature is 55°C, the pressure is 19MPa, then sterilize at 93°C for 8 minutes, inoculate the starter, the fermentation temperature is 43°C, ferment to the end of fermentation, the end point of fermentation is pH4.2, and cool down to At 22°C, add L-137 heat-sealed Lactobacillus plantarum powder to obtain fermented milk, pasteurize the fermented milk at 73°C for 23 seconds, and fill it to obtain black sesame room temperature yogurt containing citrus fiber.

[0050] The black sesame powder described in step A, preparation method is as follows:

[0051] a....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com